Home » 9 Different Types of Corrugated Retail POP Displays

9 Different Types of Corrugated Retail POP Displays

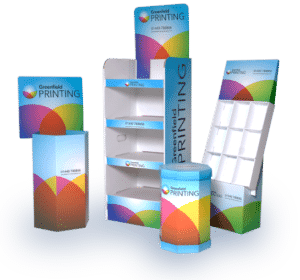

Retail point of purchase (POP) displays are essential tools for marketing products directly to consumers within retail environments. These displays vary widely in shape, size, and design, each tailored to specific marketing and placement needs. Corrugated POP displays, known for their versatility and durability, offer an array of options to suit various retail settings. Here, we explore nine popular types of corrugated POP displays, detailing their applications and benefits to help you choose the right one for your products.

What is a Corrugated Retail POP Display?

Corrugated retail POP displays are made from corrugated fiberboard, which is notable for its structural sturdiness yet lightweight properties. These displays are customized with unique structures, sizes, shapes, and folds, and are often enhanced with vibrant graphic designs, various print options, and finishes. Designed to be temporarily installed, from a day to several months, they provide a flexible and cost-effective solution for seasonal marketing or promotional campaigns.

Detailed Overview of Corrugated Retail POP Displays

Floor Display

Floor displays, or floor stands, are the quintessential type of POP display used in retail. Positioned in prominent store aisles, they provide access from multiple sides, maximizing consumer interaction.

- Applications: Ideal for new product launches or special promotions.

- Benefits: High visibility and easy accessibility increase consumer engagement and potential sales.

Full Pallet Display

These displays are built directly on a shipping pallet and are commonly seen in wholesale and bulk retail environments.

- Applications: Best for large-volume promotions or wholesale club stores.

- Benefits: They facilitate bulk selling and are easy to set up directly from the shipping pallet, reducing setup time and effort.

Half Pallet Display

Smaller than full pallet displays, these are versatile for both product showcasing and promotional uses in retail environments.

- Applications: Effective in retail settings where space is more limited but product visibility is still a priority.

- Benefits: Offers a balance between the bulk promotion of a full pallet and the space-saving design of smaller displays.

Quarter Pallet Display

Designed for small spaces, quarter pallet displays optimize retail areas by accommodating compact display needs.

- Applications: Suitable for checkout areas or in narrow aisle endcaps.

- Benefits: Maximizes retail space efficiency and is ideal for highlighting smaller product quantities.

Full Pallet Display

Half Pallet Display

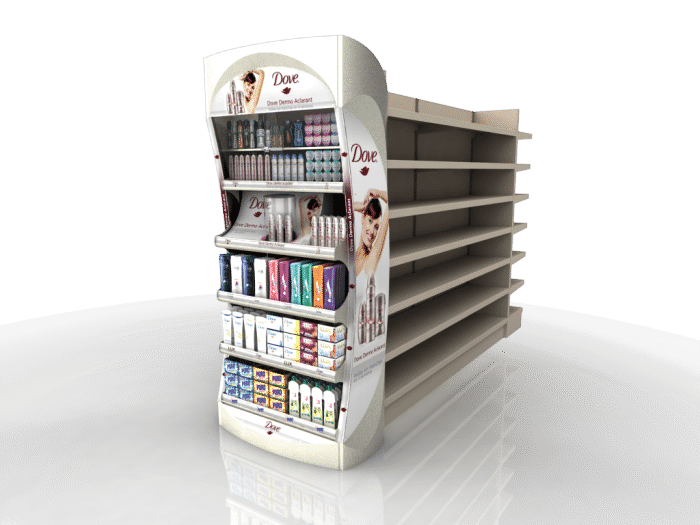

Power Wing/Sidekick

These are secondary displays attached to existing shelving or at the end of aisles using hooks or adhesives.

- Applications: Perfect for promoting small, impulse-buy items next to related products.

- Benefits: Enhances product visibility and encourages impulse purchases; easy to install and move.

Dump Bin

An open container for bulk or loose items, placed strategically to attract customers through ease of access and the allure of rummaging.

- Applications: Great for clearance items, seasonal goods, or promotional products.

- Benefits: Encourages spontaneous purchasing by making items easily accessible and visibly appealing.

Pallet Skirt/Wrap

A decorative and informative wrap around the base of a pallet, this display type is often used in warehouse-style retail environments.

- Applications: Enhances the aesthetic of bulk product displays on pallets.

- Benefits: Provides significant branding space to communicate marketing messages effectively; quick to install.

Counter Tops

Small displays designed to sit on counters or other surfaces where space is at a premium.

- Applications: Ideal for checkout areas to promote small, last-minute purchase items.

- Benefits: Utilizes otherwise wasted counter space and captures customer attention during the checkout process.

PDQ Trays

Pre-packed display trays that are easy to set up and can be placed on shelves, counters, or alongside larger displays.

- Applications: Suitable for quick setup in retail environments, offering versatility for product placement.

- Benefits: Streamlines the merchandising process, reducing labor costs and enhancing product turnover.

Dump Bin

Countertop Display

Summary: Different Types of Corrugated POP Displays

Choosing the right type of corrugated POP display can significantly impact the effectiveness of your in-store marketing efforts. By understanding the specific features and benefits of each display type, you can tailor your approach to better meet your promotional goals and engage more effectively with your target customers.

If you are interested in POP displays, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » 9 Different Types of Corrugated Retail POP Displays

In the retail environment, the placement of Point of Purchase (POP) displays is just as critical as their design and content. Strategic positioning can significantly

POP display design must serve two masters — maximizing visual impact in-store while minimizing logistics costs. Engineering the right balance between display footprint, assembly complexity,

Point-of-purchase (POP) displays do more than attract shoppers—they must also survive the complexities of modern supply chains. From manufacturing and warehousing to transportation and in-store