Home » 10 Essential Questions You Should Ask Your Packaging Supplier

10 Essential Questions You Should Ask Your Packaging Supplier

Finding the right packaging supplier for your company can be quite a challenging, time consuming, and frustrating process, since not all packaging companies are the same. Packaging companies can vary among quality standards and capabilities to products, services, who they serve and where. For your company’s success it is important for you to select the right packaging provider for your business as it can have a direct impact on your company’s operations.

A good packaging supplier should be able to meet all of your packaging needs in one place and on time (within industry standard). A quality packaging supplier will improve your business operations with efficient packaging solutions, which will help your bottom line.

Typically, a poor packaging supplier will not be able to fulfill your order to your specifications or requirements. Usually, a poor packaging supplier will provide a poor experience with delivery delays, quality issues, billing roadblocks, which will essentially cost you time and many lost opportunities for your business.

Ultimately, your packaging provider’s products, services, capabilities, quality standards, who they serve and where, should align with your company’ needs. In order to find this information, you have to ask questions to potential suppliers you are considering working with.

Overview: 10 Questions You Need To Ask Your Packaging Provider

- What Packaging Products Do You Offer?

- Do You Offer Any Services?

- Are You A Manufacturer or Distributor?

- What Is Your Expected Lead Time?

- Is There An Order Minimum?

- Can You Supply Me With Samples, If Needed?

- Can You Meet Retailer Requirements?

- Do You Have Any Recommendations Or Concerns For My Project?

- How Much Does It Cost For Delivery?

- Are You Experienced In Projects Similar To Mine?

What Packaging Products Do You Offer?

Not all packaging suppliers provide the same packaging products, as there are a large variety of packaging supplies in the market. Some suppliers focus on stock or standard products, others do custom packaging and some do both. Not every packaging supplier will sell the same product.

For example, some packaging companies focus on POP displays, some will supply foam, others focus on corrugated or chipboard boxes. You will find that some packaging companies may only offer one product and specialize in that product, while others can offer you a wide selection of stock and custom packaging.

Ultimately, depending on what packaging company you choose to question, their answer should vary from one another. It is important to keep in mind that you are looking for a packaging partner that can help you and fulfill your packaging needs.

Do You Offer Any Services?

Like products, services and capabilities of the packaging supplier can vary from one another. Services can be delivery, product and material sampling/testing, consulting, structural design, graphic design, fulfillment, and more. Some of these services can be offered in-house by the packaging supplier or it may be outsourced.

Services are usually most required when you are purchasing a custom packaging product. Stock products generally do not require services as often. Delivery services are usually universally provided by packaging suppliers.

Pick a packaging service provider that works best for you. If your supplier does not offer your desired services, then this may require you to involve another party or to find a supplier that does everything for you under them.

Are You A Manufacturer or Distributor?

Buying from a manufacturer versus a distributor can be completely different. Manufacturers tend to only provide only one or few products and services, while a distributor can provide you a wide variety of products and services.

Purchasing from a manufacturer is best when you are buying in bulk and are only seeking one item. It is important to mention that some manufacturers only work distributors and may not supply products to you.

Distributors are ideal when you are unsure about what packaging product you will need, as they can supply and recommend a variety of packaging products. If you need multiple packaging products, for example, packaging tape, boxes, edge protectors, stretch film and labels, then a distributor can help you get all that in one place. In addition, they work with a variety of manufacturers and vendors to help provide you a wide range of outsource services that you may need. Hybrid suppliers can provide some of these services in-house in addition to what a distributor can provide.

What Is Your Expected Lead Time?

It is important for you to meet your project deadlines, prevent shortages, and missed opportunities due to poor lead times. By asking your supplier when they expect your packaging order to be complete, should be a main focus on whether you choose that supplier.

Lead times can tell you a lot about your packaging supplier such as their purchasing power in the market, relationship with other suppliers, and how attentive they are to your order. This does not mean you should create unrealistic deadlines, as packaging can be complex and take time to create, however you should see if it’s comparable to other vendors you are trying to get a quote from.

In general, stock packaging products have a much lower lead time, while custom packaging products have a much longer lead time.

Is There An Order Minimum?

Manufacturers and distributors typically require order minimums when placing an order. This is because in order to remain profitable, competitive, and in business, they have to cover all costs of creating or supplying your packaging, while including a markup.

Order minimums are subjective to suppliers, some are more efficient than others in small quantities, while others are better in medium or large quantities. This is based on machinery and company capabilities, networking (for distributors). In addition, order minimums will vary based on what materials you order.

Depending on how much packaging product you will need will help influence which packaging provider will work best for you.

Can You Supply Me With Samples, If Needed?

Product and material sampling is key to a successful packaging transaction. Before placing such a large investment, it is recommended you sample your product before it is mass produced. Sampling can help you make changes to your packaging or provide you with peace of mind knowing that it meets your expectations.

Ultimately, this service can help you prevent any errors or costly mistakes in your packaging design that do not meet your company expectation or quality standards.

Can You Meet Retailer Requirements?

If you are trying to bring your product to retail, then you have to make sure your packaging meets their specifications. For example, some packaging may need to be made with sustainable material, meet safety or quality standards, or fit on their shelves, countertop, or sales floor.

Typically, this may require you to work with a packaging supplier that can consult with you through the packaging process and offer you structural design. Structural design is how you shape and size your package. This includes how it folds. Generally, retailers are picking on how products are displayed in their store, which is why consulting with a professional is vital in the structural design process.

Do You Have Any Recommendations Or Concerns For My Project?

It is important to get feedback from a prospective supplier to see whether they are engaged with your project or knowledgeable about the subject. Most packaging experts will provide you insights to your packaging requests. They will make recommendations or raise concerns for potential problems.

How Much Does It Cost For Delivery?

You should always account for shipping costs as they can vary from packaging company and where the packaging is being shipped to. Shipping costs may actually make some packaging suppliers less appealing and cost competitive, which may make it worth your while to know these costs ahead of time. Especially if you plan on doing routine business with the supplier.

Are You Experienced In Projects Similar To Mine?

Experience plays a large role in the success and value of packaging products. Experienced packaging professionals know the ins and outs of packaging such as how to improve your packaging’s cost efficiency, protection, structural integrity, storage efficiency and more.

By asking packaging suppliers if they are experienced in projects similar to yours, can help you weed inexperienced suppliers. Inexperienced manufacturers may have issues in production, while distributors may not have the best networking to give you the best value and overall cost for your project.

If you are interested in working with an experienced packaging supplier with diverse experience in serving businesses with packaging solutions, then contact Brown Packaging today.

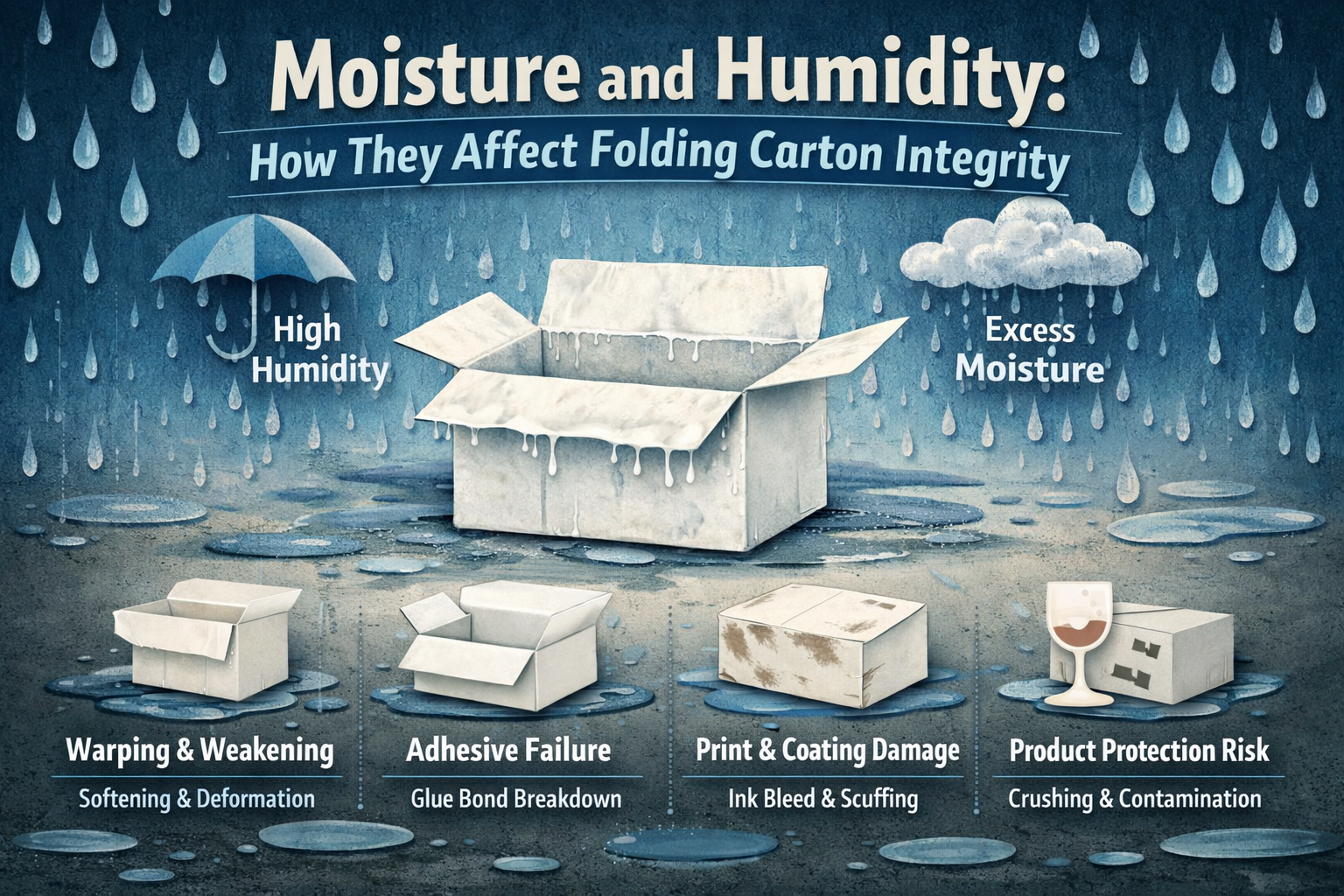

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » 10 Essential Questions You Should Ask Your Packaging Supplier

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies