Home » Wine Packaging Explained: A Guide to Storing and Displaying Wine

Wine Packaging Explained: A Guide to Storing and Displaying Wine

Wine, the elixir of celebration and sophistication, demands packaging that not only safeguards its integrity but also reflects its prestige. Whether you’re a winery owner, retailer, or wine enthusiast, understanding the intricate world of wine packaging is essential to preserving the quality of the wine and enhancing its allure. In this comprehensive guide, we explore the nuances of wine packaging, from its functional aspects to its role in brand identity and consumer experience.

The Art and Science of Wine Packaging

Wine packaging is an art that marries aesthetics with functionality. It involves creating packaging solutions that maintain the wine’s freshness, prevent oxidation, and protect it from temperature fluctuations. At the same time, packaging must capture the essence of the wine and convey the story of the vineyard and winemaking process.

Unveiling the Types of Wine Packaging

Wine packaging encompasses a variety of solutions tailored to different purposes:

- Glass Bottles: The classic choice for storing wine, glass bottles come in various shapes and sizes, each contributing to the overall wine experience. The choice of closures, such as corks or screw caps, can impact the aging process and flavor profile.

- Bag-in-Box: Offering convenience and longevity, bag-in-box packaging keeps oxygen exposure to a minimum, ensuring the wine stays fresh for an extended period after opening. This option is ideal for everyday wines.

- Cans: An emerging trend, canned wine packaging is convenient and eco-friendly. Cans are portable, lightweight, and perfect for outdoor events and picnics.

- Wine Pouches: Combining the benefits of bag-in-box and portability, wine pouches are gaining popularity. They offer a versatile option for single servings or on-the-go enjoyment.

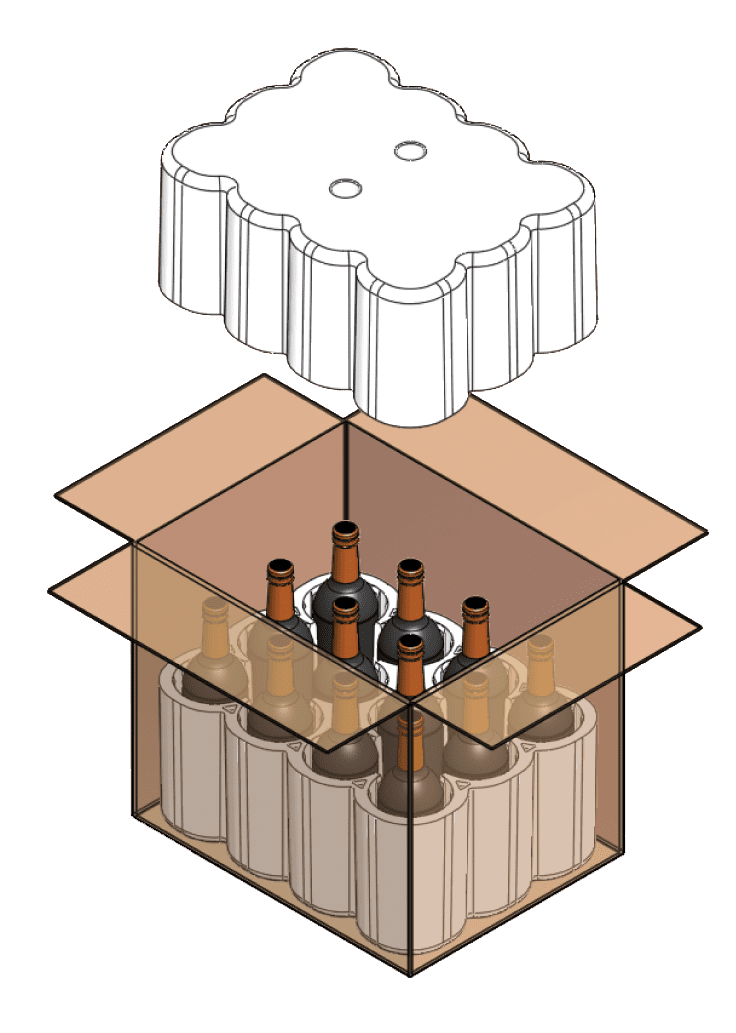

- Luxury Packaging: Premium wines often come in elaborate packaging that exudes opulence. These packages may include custom boxes, embossing, foil stamping, and unique closures.

Packaging’s Role in Brand Identity

For wineries, packaging is an extension of brand identity. The label design, choice of materials, and packaging aesthetics contribute to the perception of the wine’s quality and the winery’s values. Cohesiveness between the wine’s story, label design, and packaging creates a memorable and impactful brand experience.

Sustainability and Wine Packaging

As environmental consciousness grows, wineries are increasingly adopting sustainable packaging solutions. This includes lightweight bottles, recycled materials, and eco-friendly closures. Sustainable packaging not only aligns with consumer values but also reduces the winery’s carbon footprint.

Wine Packaging and Consumer Experience

Wine packaging significantly influences the consumer experience, from the moment they see the bottle on the shelf to the act of opening and pouring the wine. Packaging that engages the senses through tactile finishes, visually appealing designs, and informative labels enhances the overall enjoyment of the wine.

Choosing the Right Wine Packaging

When selecting wine packaging, several factors come into play:

- Wine Type: The packaging should match the wine’s style and aging potential. For instance, delicate wines may benefit from cork closures, while screw caps are ideal for wines meant for immediate consumption.

- Audience: Consider the preferences of your target audience. Younger consumers might gravitate toward innovative packaging options, while traditionalists may prefer classic glass bottles.

- Occasion: The packaging should suit the occasion for which the wine is intended. Special occasions may call for premium packaging, while everyday wines can be more practical.

Innovations in Wine Packaging

The wine industry continually evolves, and packaging is no exception. Innovations include:

- Augmented Reality Labels: Labels that come to life through augmented reality apps, offering immersive experiences and additional information.

- Smart Packaging: Packaging with embedded sensors that monitor temperature, humidity, and other factors to ensure optimal storage conditions.

Conclusion

Wine packaging is a blend of artistry, science, and storytelling. It encompasses various options designed to preserve the wine’s quality, enhance brand identity, and elevate the consumer experience. From glass bottles to sustainable solutions, wine packaging plays a critical role in presenting the wine’s character and enhancing its journey from the vineyard to the consumer’s glass. As the wine industry continues to evolve, packaging will remain a crucial avenue for innovation, creativity, and connection with wine enthusiasts worldwide.

If you are interested in wine packaging, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Wine Packaging Explained: A Guide to Storing and Displaying Wine

When it comes to packaging liquids and semi-liquids, two popular options are spout pouches and traditional bottle packaging. Both have their advantages and disadvantages, making

Wine, the elixir of celebration and sophistication, demands packaging that not only safeguards its integrity but also reflects its prestige. Whether you’re a winery owner,