Home » What is a Rigid Box?

What is a Rigid Box?

A rigid box, often referred to as a setup box, stands out in the packaging world due to its robust and durable design. Made from dense paperboard that is considerably thicker than the material used in standard folding cartons, rigid boxes are not just packaging but a statement of quality and luxury. They are fully customizable, often involving complex construction processes and high-quality materials, making them synonymous with premium branding and product presentation.

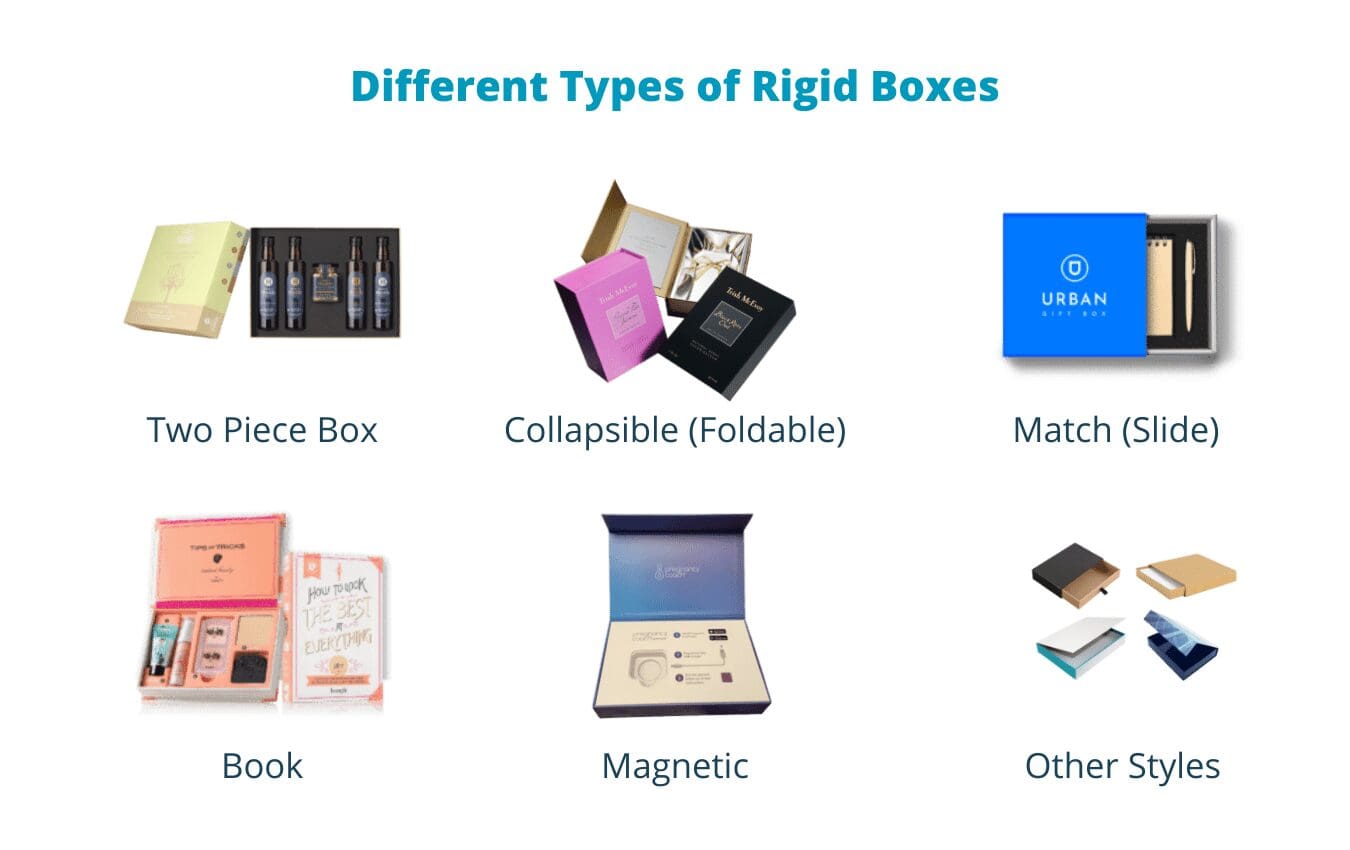

Comprehensive Overview of Rigid Box Styles

Rigid boxes are celebrated for their versatility and elegance in design. Here’s a deeper look into the various styles and their functional aesthetics:

Two-Piece Box

The quintessential model in rigid box design, the two-piece consists of a base and a lid. Simple yet elegant, this style is highly favored for its classic appearance and ease of use. It’s widely used across various industries, from high-end electronics to gourmet foods.

Collapsible (Foldable)

Innovative and practical, collapsible rigid boxes are designed to lay flat for economical storage and shipping, yet they can be easily assembled into a sturdy, structured box. This design is particularly favored by businesses looking to reduce logistical costs without compromising on packaging quality.

Match (Slide)

The match style features a tray that slides into a sleeve, offering a dynamic unboxing experience that is both smooth and engaging. It’s perfect for products that require an extra touch of interaction, such as artisanal gifts or bespoke jewelry.

Book

Mimicking the opening of a book, this style adds a narrative element to the packaging, enhancing the unboxing experience. It is ideal for special editions, collector’s items, or high-value publications.

Magnetic

Incorporating magnets for a secure and satisfying closure, magnetic boxes offer an upscale feel, often used for premium products such as designer accessories and luxury cosmetics. The magnets add a level of sophistication and functionality, ensuring the contents are safely enclosed. Learn more about magnetic boxes.

Other Innovations

Beyond these common types, rigid boxes can also be crafted with unique features like hinged/flip lids, shoulder/neck constructions, or even round shapes, tailored to specific product dimensions and brand aesthetics.

Applications and Uses of Rigid Boxes

Due to their sturdy construction and elegant appearance, rigid boxes are predominantly used for:

- High-End Electronics: Providing excellent protection and a premium unboxing experience for gadgets.

- Luxury Cosmetics: Enhancing the brand value and shelf presence of beauty products.

- Fine Jewelry: Offering a secure and attractive packaging solution that matches the item’s luxury.

- Gifts and Specialties: Making occasions more memorable through beautifully designed packaging.

Advantages of Choosing Rigid Boxes

Choosing a rigid box for your product packaging brings several benefits:

- Enhanced Product Protection: The sturdy construction ensures that contents are well-protected against impacts and compression.

- Elevated Brand Perception: The quality and elegance of rigid boxes enhance the perceived value of the contents, influencing customer satisfaction and loyalty.

- Customization Opportunities: From size and shape to finishes and printing techniques, every aspect can be tailored to create a unique packaging solution that reflects the brand’s identity.

- Sustainable Options: Many rigid boxes can be produced using recycled materials and can be recyclable themselves, aligning with eco-friendly brand values.

Key Considerations for Rigid Box Packaging

While rigid boxes offer unparalleled elegance and protection, they come with considerations that may impact their suitability:

- Cost: The premium materials and customized manufacturing processes can make rigid boxes more expensive than other types of packaging.

- Practicality: For some products, especially those that are low-cost or require frequent access, a rigid box may not be the most practical choice.

- Minimum Order Quantities: Custom rigid box manufacturers often require large minimum orders, which can be a barrier for smaller businesses or those requiring limited runs.

Conclusion: The Strategic Value of Rigid Boxes

Rigid boxes are not just packaging; they are a strategic tool for enhancing brand prestige and improving customer experience. They are best suited for products that require a high level of protection or brands aiming to make a strong impact on the market. With the ability to fully customize the design and features, rigid boxes offer a packaging solution that truly stands out.

If you are considering this type of packaging, partnering with a specialized provider like Brown Packaging will ensure that your packaging not only meets your aesthetic and functional needs but also aligns with your strategic branding objectives.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » What is a Rigid Box?

Holiday e-commerce volumes push packaging to its limits. Trailers are overfilled, handling is rushed, and parcels endure more drops and vibration than usual. Without proper

Understanding consumer psychology is paramount to creating effective point of purchase (POP) displays. These strategically placed displays can significantly influence a customer’s decision to make

The visual appeal of a product often determines its success in the market. In today’s competitive retail environment, innovative packaging designs have become a crucial