Home » The Cost of Packaging in 2022

The Cost of Packaging in 2022

In 2022, businesses are experiencing a challenging time with increased cost of packaging materials such as corrugated, plastic, chipboard, thermoform, and other products. In addition, many are experiencing longer lead times for orders and may find themselves unfilled in meeting their deadlines. If you are invested in the packaging industry, then you probably have asked yourself what is causing such an increase in price.

Why The Cost Of Packaging Has Increased In 2022

Current events such as the Ukraine-Russia war, Covid-19 pandemic and other world events have impacted the global supply chains of raw materials. In addition, the rise of inflation and fuel prices have also influenced the increased prices.

The growth of packaging production is not exceeding the increased demand of consumers. Manufacturers and suppliers are struggling to get required raw materials to fulfill their orders.

For example, earlier this year, corrugated suppliers have increased the price of raw materials by $60-$70/ton. Prices of major packaging resins, such as Polyethylene (PET), have increased in price by $0.46/b in the last two years.

With increased prices of oil and energy, packaging is expected to continue to increase. Labor shortages in transportation and lack of shipping containers have also added to supply chain inefficiencies and delays.

How To Keep Your Packaging Cost Low in 2022

Businesses are struggling to meet their packaging projects and consumer expectations with current costs. Many are often finding themselves having to cut back on their order quantities, design, and expectations. However, by working with an established packaging distributor you can have the best chance of getting the best price for your packaging.

Established packaging distributors have a large network of manufacturers that specialize in creating different products, whether they are corrugated, foam, plastic, or printed in a specific way. Distributors are able to outsource your packaging needs to manufacturers that specialize in manufacturing your package.

For example, not all corrugated manufacturers can produce large quantities of double sided digital print boxes at the same price. At the same time, not many can produce those boxes at a low quantity at a low price. Every manufacturer specializes in specific packaging needs and distributors have the flexibility and accessibility to working with a wide range of these manufacturers.

Additionally, you would want to work one on one with a packaging professional that can advise you on the best approach for all of your packaging needs. A packaging consultant can help you get the most value out of your packaging project while minimizing your costs.

For example, if you are packaging a specific product with corrugated material in mind, they may recommend a cheaper and more efficient packaging such as chipboard or paperboard material. Perhaps, digital print may be cheaper for your project or it may be flexoprint.

The more informed you are with your packaging decisions the more you will be able to save on cost in 2022. If you are interested in packaging products, services, and consulting, then contact Brown Packaging today to get started.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

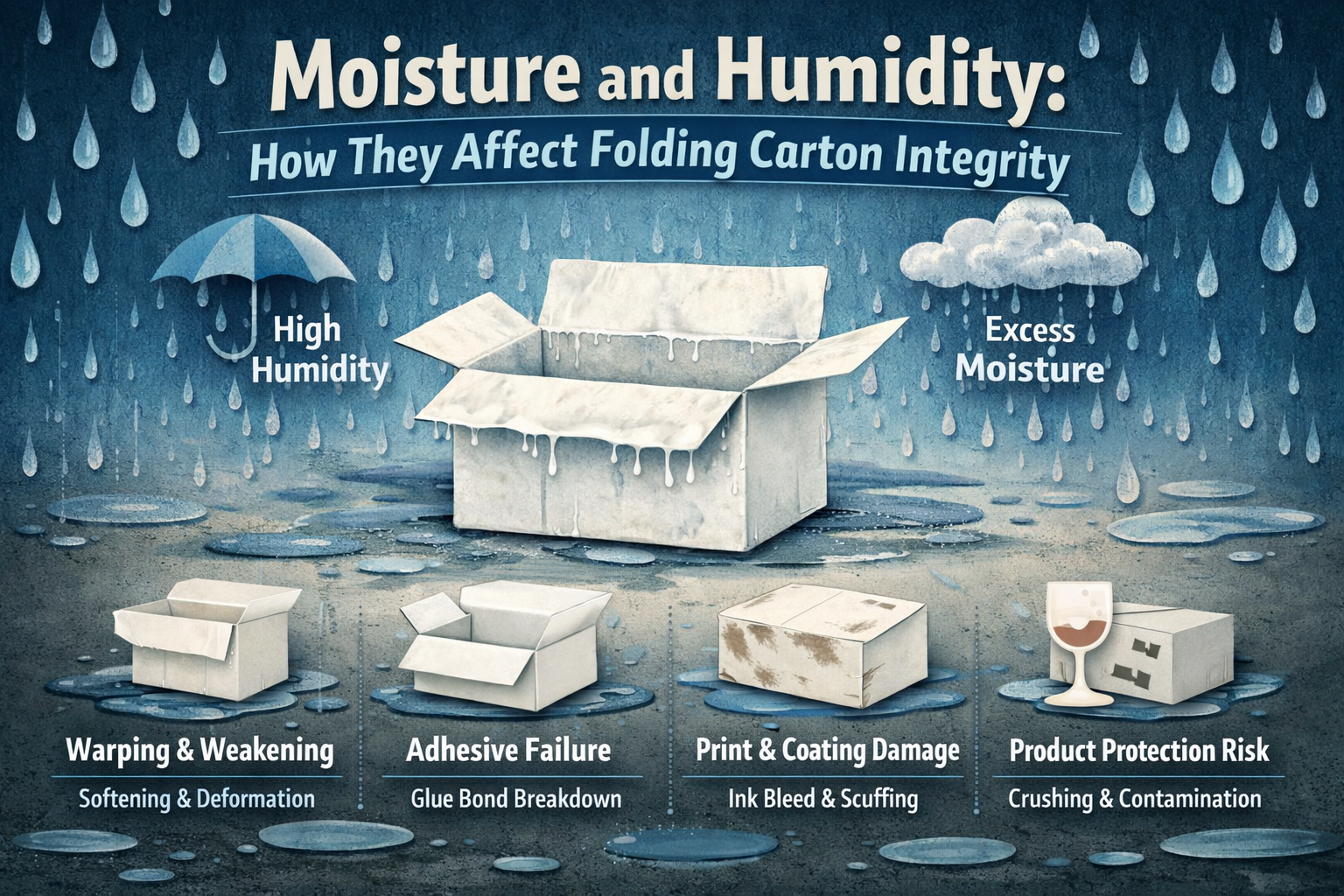

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » The Cost of Packaging in 2022

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected