Sustainable Pouches

We offer a wide range of sustainable pouches in various styles and materials, designed to meet all your packaging needs. Our options include eco-friendly print and ink choices, ensuring your packaging is both attractive and environmentally responsible. All our pouches comply with the latest sustainability standards, helping you meet your green goals.

Sustainable Pouches

We offer sustainable pouches in a variety of styles and materials. Choose from eco-friendly print and ink options that meet sustainability standards. Our pouches are designed to help you achieve your green goals.

How We Can Help Make Your Pouches Sustainable

We offer a range of sustainable pouch solutions and certification assistance to meet your eco-friendly packaging needs. From providing eco-conscious materials to ensuring your pouches meet recognized sustainability certifications, we help make your packaging both high-quality and environmentally responsible.

Pouch Styles

We offer a complete range of corrugated boxes, available in custom and stock options to suit your specific packaging needs. Our boxes are designed to meet various burst strengths and edge crush test (ECT) ratings, ensuring durability and reliability for your requirements.

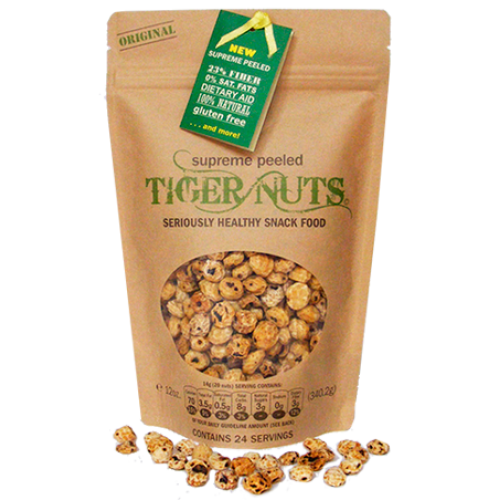

Stand up pouches feature a bottom gusset that allows them to stand upright on shelves, providing excellent visibility and convenience. These pouches are ideal for packaging snacks, dried fruits, pet foods, and other similar products. The resealable zipper option helps maintain product freshness and provides ease of use for consumers.

Designed for high-temperature processing, these pouches are ideal for packaging ready meals and heat-sterilized foods. Their durable structure ensures long shelf life and the ability to withstand extreme heat. Commonly used for soups, sauces, and pre-cooked meals, they offer a lightweight and space-saving alternative to traditional cans.

Lay flat pouches, also known as pillow pouches, lie flat and are perfect for single-use items. They are commonly used for packaging snacks, confectioneries, and small quantities of pet treats. Their simple design makes them cost-effective and easy to produce, while maintaining the freshness of the contents.

Gusseted pouches have expandable sides or bottoms, allowing them to hold larger volumes and stand upright. These pouches are ideal for coffee, tea, grains, and other bulk products. The gusset design provides additional strength and stability, making them a versatile choice for various packaging needs.

Block bottom pouches combine the benefits of stand-up and gusseted pouches, featuring a flat base that allows them to stand firmly. They are ideal for heavier products like flour, sugar, and pet food. The block bottom design maximizes storage capacity and shelf presence, making them an attractive option for retail displays.

Sachets are small, single-use pouches perfect for packaging samples, spices, and single servings of products. Their compact design makes them convenient for on-the-go use and easy to distribute. Often used in the food, cosmetic, and pharmaceutical industries, sachets provide a hygienic and cost-effective packaging solution.

Spout pouches feature a convenient spout for easy pouring and dispensing of liquids and semi-liquids. These pouches are commonly used for packaging beverages, sauces, baby food, and detergents. The spout design ensures minimal spillage and allows for resealing, maintaining product freshness and ease of use.

Sample pouches are small, single-use pouches designed for distributing product samples. They are ideal for cosmetics, skincare products, and food items, allowing customers to try a product before committing to a full-size purchase. These pouches are cost-effective and provide a great marketing tool for promoting new products.

Stick packs are long, narrow pouches designed for single-serving portions. They are perfect for packaging powdered products like instant coffee, drink mixes, and supplements. Their compact and portable design makes them convenient for on-the-go consumption and easy to use.

Roll stock refers to continuous film rolls used for automatic packaging machines. This material can be customized with various prints and laminations and is suitable for packaging snacks, candy, and other food products. Roll stock allows for efficient, high-speed production, reducing packaging time and costs.

We offer a variety of other pouch styles tailored to your specific needs. If you don’t see the style you’re looking for, please contact us to discuss your requirements. Our team is ready to help you find the perfect packaging solution for your product.

Material Options

We offer a variety of sustainable pouch materials to meet your eco-friendly packaging needs. Choose from options like recycled polyester, compostable films, kraft paper, bio-based polyethylene, cellophane, and polylactic acid to ensure your packaging is both high-quality and environmentally responsible.

Made from post-consumer recycled plastics, rPET reduces waste and supports recycling initiatives. It provides excellent durability and strength, making it suitable for food and beverage packaging.

Compostable films break down completely in composting environments and are made from renewable resources like cornstarch or PLA. They are ideal for packaging snacks, fresh produce, and other perishable items.

Kraft paper is a biodegradable and strong material used for packaging dry goods, coffee, tea, and baked products. Its natural look adds an eco-friendly appeal to the packaging.

Bio-PE, derived from renewable sources like sugarcane, offers a sustainable alternative to conventional polyethylene. It is suitable for a wide range of products, including liquids and powders.

Cellophane, made from cellulose derived from wood pulp, is biodegradable and compostable. It is commonly used for packaging candies, baked goods, and other dry food products.

PLA is a compostable bioplastic made from fermented plant starch, usually corn. It is used for food packaging and single-use items, decomposing under industrial composting conditions.

Sustainable Print and Ink Options

Explore our eco-friendly print and ink options for pouches, designed to ensure high-quality results while minimizing environmental impact. We use sustainable inks and printing processes that reduce harmful emissions and are safer for the environment, providing you with a greener choice without compromising on visual appeal.

Digital Printing Digital printing eliminates the need for plates and significantly reduces waste during the printing process. This method allows for on-demand printing, reducing overproduction and excess inventory. Digital printing is versatile and efficient, suitable for short runs and customized packaging solutions. It supports sustainability by minimizing material waste and energy consumption.

- Applications: Ideal for short-run packaging, personalized products, and rapid prototyping.

- Sustainability Level: High, as it reduces waste, energy use, and allows for precise inventory management.

Flexographic printing uses flexible plates and fast-drying inks, making it an efficient choice for large-scale packaging production. This method can be combined with sustainable inks to further reduce environmental impact. Flexographic printing is versatile and suitable for a variety of substrates, ensuring high-quality prints. It supports sustainability by being adaptable to eco-friendly inks and materials.

- Applications: Suitable for flexible packaging, labels, and large-scale production runs.

- Sustainability Level: Moderate to high, depending on the inks and materials used.

Offset printing offers high-quality and consistent prints, particularly suitable for larger production runs. This method can be made more sustainable by using recycled paper and eco-friendly inks. Offset printing is known for its precision and ability to handle detailed images. It supports sustainability through efficient production processes and compatibility with sustainable materials.

- Applications: Ideal for larger production runs, detailed images, and high-quality prints.

- Sustainability Level: Moderate, with potential for high sustainability when using eco-friendly materials and inks.

Digital printing eliminates the need for plates and significantly reduces waste during the printing process. This method allows for on-demand printing, reducing overproduction and excess inventory. Digital printing is versatile and efficient, suitable for short runs and customized packaging solutions. It supports sustainability by minimizing material waste and energy consumption.

- Applications: Ideal for short-run packaging, personalized products, and rapid prototyping.

- Sustainability Level: High, as it reduces waste, energy use, and allows for precise inventory management.

Flexographic printing uses flexible plates and fast-drying inks, making it an efficient choice for large-scale packaging production. This method can be combined with sustainable inks to further reduce environmental impact. Flexographic printing is versatile and suitable for a variety of substrates, ensuring high-quality prints. It supports sustainability by being adaptable to eco-friendly inks and materials.

- Applications: Suitable for flexible packaging, labels, and large-scale production runs.

- Sustainability Level: Moderate to high, depending on the inks and materials used.

Offset printing offers high-quality and consistent prints, particularly suitable for larger production runs. This method can be made more sustainable by using recycled paper and eco-friendly inks. Offset printing is known for its precision and ability to handle detailed images. It supports sustainability through efficient production processes and compatibility with sustainable materials.

- Applications: Ideal for larger production runs, detailed images, and high-quality prints.

- Sustainability Level: Moderate, with potential for high sustainability when using eco-friendly materials and inks.

Soy-based inks are made from soybean oil and are biodegradable, providing a renewable alternative to petroleum-based inks. These inks produce sharp, vibrant colors and are easier to de-ink during the recycling process. They are widely used in offset and flexographic printing, making them a popular choice for eco-conscious printing. Soy-based inks help reduce carbon footprint and support sustainable agriculture.

- Applicable to: Flexographic, Offset

- Sustainability Level: High, due to renewable sources and biodegradability

- Cost Level: Moderate, generally comparable to traditional inks

- Advantages: Environmentally friendly, vibrant colors, easier to recycle

- Disadvantages: May not be suitable for all substrates, longer drying times compared to petroleum-based inks

Water-Based Inks Water-based inks are eco-friendly and contain fewer harmful solvents, reducing VOC emissions. These inks offer vibrant colors and are suitable for various substrates, providing a high-quality finish. They are widely used in both flexographic and digital printing due to their environmental benefits. Water-based inks support safer working conditions and sustainability efforts.

- Applicable to: Digital, Flexographic

- Sustainability Level: High, due to low VOC emissions and reduced environmental impact

- Cost Level: Moderate, generally more affordable than solvent-based inks

- Advantages: Environmentally friendly, low odor, good color quality

- Disadvantages: Longer drying times, may require specialized equipment for best results

UV-cured inks dry instantly when exposed to ultraviolet light, reducing the need for solvents and improving production speed. These inks are durable, resistant to fading, and provide excellent adhesion to various materials. They are commonly used in flexographic and digital printing, offering high-quality and efficient printing solutions. UV-cured inks contribute to reduced energy consumption and waste.

- Applicable to: Digital, Flexographic, Offset

- Sustainability Level: Moderate to high, as they eliminate solvents but require UV light curing

- Cost Level: High, due to the need for specialized curing equipment

- Advantages: Instant drying, high durability, vibrant colors

- Disadvantages: Higher initial investment, potential health risks from UV exposure

Algae-based inks are an innovative and sustainable alternative, derived from algae cells. These inks are renewable, biodegradable, and have a lower carbon footprint compared to traditional inks. They provide vibrant colors and are suitable for both digital and flexographic printing. Algae-based inks promote a circular economy and offer a cutting-edge solution for sustainable printing.

- Applicable to: Digital, Flexographic

- Sustainability Level: High, due to renewable and biodegradable properties

- Cost Level: High, as they are relatively new and less widely available

- Advantages: Environmentally friendly, vibrant colors, supports circular economy

- Disadvantages: Higher cost, limited availability

Vegetable-based inks are made from various vegetable oils, offering a sustainable alternative to petroleum-based inks. These inks provide good color quality and are biodegradable, making them suitable for flexographic and offset printing. They help reduce environmental impact and support the use of renewable resources. Vegetable-based inks are a versatile and eco-friendly choice for printing.

- Applicable to: Flexographic, Offset

- Sustainability Level: High, due to renewable sources and biodegradability

- Cost Level: Moderate, similar to other eco-friendly inks

- Advantages: Environmentally friendly, good color quality, biodegradable

- Disadvantages: May not be suitable for all printing applications, longer drying times

Aqueous inks are water-based and designed to be environmentally friendly, containing fewer harmful chemicals. They provide high-quality prints and are suitable for both digital and flexographic printing. These inks dry quickly and are ideal for various substrates, offering a versatile and sustainable printing solution. Aqueous inks support reduced VOC emissions and safer printing processes.

- Applicable to: Digital, Flexographic

- Sustainability Level: High, due to low VOC emissions and minimal environmental impact

- Cost Level: Moderate, generally more affordable than solvent-based inks

- Advantages: Quick drying, environmentally friendly, high-quality prints

- Disadvantages: May require specialized equipment, less durable than solvent-based inks

Interested In Sustainable Pouch Packaging?

Frequently Asked Questions

Learn more about sustainable pouch packaging, including style options, order minimums, lead time and more. Discover information to help you make informed decisions about eco-friendly packaging solutions tailored to your needs.

Expert Consulting

Our expert consulting services provide tailored guidance and strategic insights to help you make informed packaging decisions and optimize your packaging processes.

Digital Print

Utilizing advanced in-house digital printing technology, we offer high-quality printed samples that showcase your packaging design concepts effectively.

Structural Design

Our structural design expertise ensures your packaging is not only visually appealing but also optimized for functionality, protection, and cost-efficiency.

Sampling

We provide sampling services to help you evaluate and refine your packaging prototypes, allowing you to make data-driven decisions before full-scale production.

Graphic Design

Our graphic design team specializes in creating captivating visuals, ensuring your packaging communicates your brand identity and product messaging effectively.

Product & Material testing

We offer comprehensive product and material testing to guarantee the durability, safety, and compliance of your packaging, assuring its suitability for your specific industry and requirements.

Order minimums vary from project to project, it usually depends on the type of packaging, design, size and desired materials. Contact us and we will evaluate the best options for your packaging needs.

Shipping is free to all Southern California businesses. Fees are generally added to orders outside of Southern California or if you need a rush order. We also deliver to all of the United States, in which prices for shipping can vary.

Selecting the right pouch for your product is crucial for ensuring proper protection, shelf appeal, and meeting sustainability goals, which ultimately enhances customer satisfaction and brand reputation.

We Are Retail Compliant:

We offer sustainable pouches that comply with the requirements of major retailer chains and club stores, ensuring your packaging meets industry standards for environmental responsibility and quality. Our pouches align with guidelines from leading retailers like Walmart, Costco, and Whole Foods, providing seamless integration into their supply chains. Choose our eco-friendly packaging solutions to enhance your product’s appeal and support sustainability.

We Are Gov. Compliant:

We offer sustainable pouches that comply with government regulations, ensuring your packaging meets all necessary standards for safety and environmental responsibility. Our pouches are designed to align with guidelines from agencies such as the FDA, USDA, and EPA, providing you with assurance of regulatory compliance. Choose our eco-friendly packaging solutions to meet legal requirements and support sustainability.

To dive deeper into sustainable packaging, we invite you to explore our blog, which features a wealth of information on eco-friendly practices, innovations in sustainable materials, and expert insights. Our blog is regularly updated to help you stay informed about the latest trends and developments in sustainable packaging. Visit our blog to learn more and take your knowledge to the next level.

Sustainability has become a crucial issue in recent years, and more and more businesses are adopting sustainable practices to reduce their environmental impact. One area

As environmental concerns continue to dominate consumer and regulatory conversations, the packaging industry is responding with innovative, eco-friendly solutions. In 2025, sustainable packaging will not

Sustainability is growing momentum in 2023 for the packaging industry, as many businesses worldwide are looking to further limit their carbon footprint and maximize recyclability.