Sustainable Packaging

Explore our sustainable packaging products, including corrugated boxes, folding cartons, pouches, and stock packaging options. We offer eco-friendly materials and a variety of print and ink choices to fit your packaging needs. Choose from solutions designed to support sustainability and meet your business requirements.

Sustainable packaging refers to the use of materials and design methods that minimize environmental impact. This can include using recyclable or biodegradable materials, reducing excess packaging, and opting for renewable resources like paper, kraft, or corrugated materials. The goal is to reduce waste, conserve energy, and lessen the overall carbon footprint of packaging.

By choosing sustainable packaging, businesses help limit the negative effects of packaging waste on the environment. These products are often recyclable, compostable, or reusable, making them a more eco-friendly option. Sustainable packaging balances the need for protection and branding with the responsibility to preserve resources for future generations.

Our sustainable packaging products include custom corrugated boxes, folding cartons, pouches, and a variety of stock options. Each product is designed with eco-friendly materials to help reduce environmental impact while meeting your packaging needs.

Corrugated Boxes

- Regular slotted Container (RSC)

- Half Slotted Container (HSC)

- Full Overlap (FOL)

- Roll End Tuck Top (RETT/Mailer)

- Additional Box Styles

- Corrugated Inserts

Folding Cartons

- Straight Tuck End (STE)

- Reverse Tuck End (RTE)

- Full Seal

- Auto Bottom

- Chipboard Inserts

Pouches

- Stand Up

- Lay Flat

- Gusseted

- Retort

- Block Bottom

- Sachets

- Additional Pouch Styles

Stock Packaging Products

- Corrugated Packaging

- Shipping Boxes

- Chipboard Packaging

- Edge Protectors

- Mailers (Kraft)

- Kraft Tape

- Kraft Paper

At Brown Packaging, we prioritize eco-friendly packaging solutions that help reduce environmental impact. Our commitment to green packaging ensures that we provide sustainable materials, allowing you to make responsible choices for your business and the planet.

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Today, many consumers are increasingly seeking sustainable products over cheaper alternatives that are less environmentally friendly. According to a global study by Nielsen, millennials, in particular, are willing to pay more for sustainable options, but they aren’t willing to compromise on quality in the process.

At Brown Packaging, we are committed to delivering innovative, eco-friendly packaging solutions that create a better future without sacrificing quality. Whether you need stock or custom packaging, we help reduce your environmental footprint with materials that are recyclable, biodegradable, or compostable. Our focus is on balancing sustainability with the performance and durability your business requires.

- Fully Customizable

- Wide Product Selection

- Recyclable

- Biodegradable

- Compostable

- Environment Friendly Print Options and more

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

Recyclable, Biodegradable, and Compostable Packaging

When it comes to sustainability, recycling is often the most commonly discussed concept by consumers, the media, and businesses alike. However, many companies are increasingly exploring biodegradable and compostable packaging as viable alternatives to traditional recycling methods.

Recyclable packaging is designed to be processed and reused after its initial use, reducing the need for new raw materials and minimizing waste. It can be collected through recycling programs and converted into new products, helping to conserve resources and lower environmental impact. Common examples of recyclable packaging include materials like cardboard, paper, certain plastics, and metals, which can be easily sorted and reintroduced into the manufacturing cycle.

Biodegradable packaging is made from materials that naturally break down over time through the action of microorganisms, such as bacteria or fungi, without leaving harmful residues. This type of packaging is designed to decompose in the environment, helping to reduce waste in landfills and minimize pollution. Typically made from natural or plant-based materials like paper, cornstarch, or bioplastics, biodegradable packaging offers an eco-friendly alternative to traditional packaging by returning to nature without damaging the ecosystem.

Compostable packaging is designed to break down into natural elements under specific composting conditions, leaving no toxic residue behind. It typically decomposes more quickly than biodegradable packaging and must meet certain standards to ensure it fully returns to the earth as nutrient-rich compost. Made from materials like plant-based fibers or biodegradable plastics, compostable packaging provides an eco-friendly option that contributes to healthier soil when processed in commercial or home composting environments.

As sustainability becomes a top priority for businesses and consumers alike, compostable and biodegradable packaging are now essential components of eco-friendly practices. With increasing regulations and growing consumer demand for environmentally responsible products, companies must adapt to greener packaging solutions to remain competitive and compliant. The shift toward sustainable packaging is no longer optional—it’s a necessity for businesses aiming to meet modern expectations.

At Brown Packaging, we specialize in providing tailored packaging solutions that not only meet industry standards but also promote environmental responsibility. From retail compliance to government regulations, we work closely with clients to create packaging that balances performance, sustainability, and innovation, ensuring your brand stays ahead in a rapidly evolving marketplace.

We provide packaging solutions designed to help reduce your carbon footprint through eco-friendly production, efficient shipping, and sustainable materials. From pallet optimization to energy-efficient manufacturing, our approach ensures that your packaging minimizes environmental impact at every stage.

Our custom structural design services allow us to minimize material use without compromising protection. By optimizing the design for strength and efficiency, we help you reduce excess packaging and the environmental costs associated with waste. Smarter packaging design means a lower carbon footprint overall.

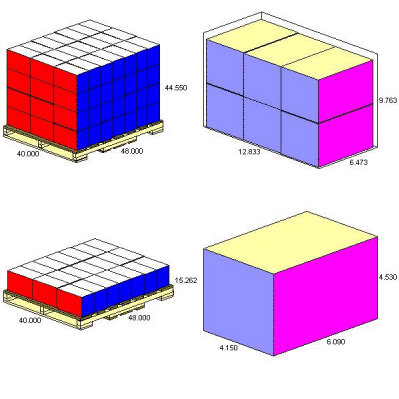

With CAPE software, we optimize pallet configurations to maximize space and load efficiency. This results in fewer trips and lower fuel usage during transportation, reducing your carbon footprint. By making the most of every pallet, we help you achieve more eco-friendly logistics.

We offer digital samples, eliminating the need for multiple physical prototypes, which reduces waste and energy use in production. By creating virtual models, we help you save resources while speeding up the design process. This eco-friendly approach helps minimize the carbon footprint of packaging development.

We focus on eco-friendly production processes that minimize waste and reduce energy consumption. By using sustainable materials and optimizing manufacturing efficiency, we help lower the carbon footprint of your packaging. This commitment to sustainable production ensures a smaller environmental impact from the start.

Our lightweight and efficient packaging solutions help reduce transportation emissions by maximizing space and minimizing weight. By designing packaging that is easy to transport, we help your business cut down on fuel consumption and overall shipping costs, contributing to a reduced carbon footprint.

We design packaging with durability and reusability in mind, extending the useful life of each product. By creating packaging that can be used multiple times before disposal or recycling, we help reduce waste and conserve resources, contributing to a smaller environmental footprint.

We prioritize sourcing materials from local suppliers to reduce transportation distances and emissions. By keeping production and distribution close to home, we help cut down on the environmental impact associated with long-distance shipping. Local sourcing ensures a more sustainable and efficient supply chain.

We offer packaging made from eco-friendly, recyclable, and biodegradable materials that reduce reliance on virgin resources. By using sustainable materials, we help decrease the carbon emissions associated with material extraction and production. This ensures that your packaging has a smaller environmental impact from the very start.

Interested In Sustainable Packaging Solutions?

Discover the latest insights on sustainable packaging by exploring our blog, where we share tips and innovations to help businesses reduce their environmental impact. Stay informed about eco-friendly packaging solutions and learn how your company can make a difference through sustainability.

In the competitive landscape of retail, where countless products vie for consumer attention, ‘shelf impact’ is a term that resonates strongly with brands and marketers. Shelf impact refers to the visual appeal and distinctiveness of a product when placed on a store shelf, surrounded by competing products. This blog post delves into why shelf impact is essential in packaging design and how it can influence a brand’s success in the marketplace. Understanding Shelf Impact Shelf impact is about making a product stand out in a crowded retail environment. It’s the immediate visual appeal and recognition a product garners when a consumer scans store shelves. Good shelf impact can lead to increased brand awareness, consumer recall, and ultimately, sales. The Significance of Shelf Impact in Packaging First Impressions Count: Consumers often make purchasing decisions within seconds. Eye-catching packaging can grab attention and influence these split-second decisions. Packaging is often the first interaction a consumer has with a product, making it a critical touchpoint. Differentiation in a Saturated Market: In a market flooded with similar products, distinctive packaging can set a product apart. Unique design elements, colors, shapes, and textures can differentiate a product from its competitors. Brand Identity and Perception: Packaging that stands out on a shelf can enhance brand recognition and reinforce brand identity. High-quality, innovative packaging can elevate a product’s perceived value and position it as a premium offering. Encouraging Impulse Purchases: Visually striking packaging can trigger impulse buys, especially for products that consumers do not pre-plan to purchase. Strategies to Maximize Shelf Impact Vibrant and Unique Color Schemes: Utilize colors that pop or are different from competitors to catch the consumer’s eye. Consider color psychology and how different colors evoke different emotions and perceptions. Innovative Packaging Design: Experiment with unusual shapes or structural designs that stand out visually. Incorporate unique features like windows to showcase the product or interactive elements. Clear and Compelling Branding: Ensure that branding is prominent and easily recognizable. Use typography and logo placement strategically to create visual interest and brand recognition. High-Quality Graphics and Imagery: Employ high-resolution graphics and attractive imagery that resonates with the target audience. Packaging should tell a story or convey a message that aligns with the brand’s values. Material and Finishing Choices: Select materials that contribute to the overall appeal and feel of the packaging. Finishes such as matte, gloss, embossing, or foil accents can add a touch of luxury and refinement. Understanding Consumer Behavior and Trends Stay informed about current trends in design and consumer behavior. Conduct market research to understand what visual elements appeal to your target demographic. Sustainability and Shelf Impact Incorporating sustainable packaging solutions can positively impact consumer perception, as eco-friendliness is increasingly valued. Use sustainable materials in a way that enhances visual appeal, like natural textures or eco-labels. Testing and Feedback Use focus groups and consumer testing to gauge the shelf impact of different packaging designs. Regularly review and update packaging based on consumer feedback and market trends. If you are interested in shelf packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

When it comes to packaging, two critical elements come into play – structural design and graphic design. Both are essential in their ways, but depending on your audience, one may hold more significance than the other. This blog post delves into the nuances of structural and graphic design in packaging and examines which aspect resonates more with different types of audiences. Understanding Structural and Graphic Design in Packaging Structural Design refers to the physical shape and functionality of the packaging. It’s about how the package is constructed, how it protects the product, and how it functions from a user’s perspective. Graphic Design, on the other hand, involves the visual elements on the packaging’s exterior. This includes the use of colors, fonts, images, and other graphical elements that communicate the brand and attract the consumer. Structural Design: The Functional Communicator Structural design is crucial when the audience prioritizes functionality, usability, and convenience. This aspect is particularly important in: Products Requiring Safe Transit: For fragile or high-value items, the structural design ensures safety and integrity. Consumer Convenience: Products aimed at offering convenience, like easy-to-open or resealable packaging, appeal more through their structural design. Innovative Niche Markets: In markets where innovation is highly valued, unique structural designs can make a significant impact. Graphic Design: The Visual Storyteller Graphic design becomes a dominant factor when the audience is influenced by brand story, aesthetics, and emotional connection. It’s significant in: Lifestyle and Luxury Products: For products where brand perception and aesthetic appeal are crucial, graphic design takes center stage. Products Aimed at Younger Audiences: Younger demographics often respond strongly to visually appealing and trendy designs. Brand-Driven Products: When the brand story and identity are integral to the product, graphic design helps in forging that connection with the audience. Balancing Both for Maximum Impact In most cases, a balance of both structural and graphic design is necessary to fully engage your audience. This balance can be achieved by: Understanding Customer Preferences: Conduct market research to understand what your audience values more – functionality or aesthetics. Cohesive Design Strategy: Ensure that both structural and graphic designs complement each other and align with the overall brand strategy. Innovative Blending: Experiment with innovative ways to blend structural and graphic elements for a unique packaging experience. Considerations Based on Product Type and Audience FMCG Products: Fast-moving consumer goods often rely on graphic design for quick shelf impact but require structurally sound packaging for transportation and storage. Tech Products: For tech products, structural design often takes precedence for protection, but graphic design plays a key role in brand positioning. If you are interested in structural and/or graphic design for your packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Corrugated boxes are a staple in the packaging world, known for their strength and versatility. However, maximizing their durability is key to ensuring products reach their destinations safely. This blog post explores effective strategies for enhancing the durability of corrugated boxes, ensuring they withstand the rigors of shipping and handling. Understanding Corrugated Boxes Before diving into durability enhancement, it’s crucial to understand what corrugated boxes are. Made from corrugated fiberboard, these boxes consist of a fluted corrugated sheet and one or two flat linerboards. The flutes between the liners offer strength and cushioning, making these boxes ideal for a wide range of products. Selecting the Right Material The choice of material is fundamental in determining a box’s durability. Flute Profiles: Corrugated boxes come in various flute sizes – A, B, C, E, and F. Each offers different levels of strength and compression resistance. For instance, A-flute provides the highest cushioning, while B-flute is more rigid and excellent for printing. Board Grade: The strength of the corrugated board, measured in terms of the bursting strength and edge crush test (ECT), is also vital. Higher ECT-rated boxes are more durable and withstand higher stacking pressures. Optimal Design and Construction The design and construction of the box significantly impact its durability. Box Style: Choose a box style suited to your product. For example, Regular Slotted Containers (RSCs) are a standard choice for many products, but for heavier items, a Full Overlap (FOL) style can offer extra strength. Wall Construction: Consider using double-wall or even triple-wall corrugated boxes for added durability, especially for heavier or more fragile items. Proper Sizing and Fit Ensuring that your product fits well within the corrugated box is essential. Avoid Oversizing: Too much space can cause the contents to shift and become damaged. Use appropriate void fillers if necessary. Custom Sizing: Custom-sized boxes reduce the need for additional packing materials and provide better protection. Sealing and Closure A strong seal is critical to maintaining the integrity of the box. Quality Adhesives: Use high-quality tape or glue. Reinforced water-activated tape is often a strong choice for sealing corrugated boxes. Proper Sealing Techniques: Apply tape evenly across the box’s center seam and down the sides to reinforce the box’s edges. Handling Instructions Clearly marked handling instructions can enhance the durability by ensuring proper handling. Label Appropriately: Use labels such as “Fragile,” “Handle With Care,” or “This Side Up” to encourage careful handling during transit. Visibility of Instructions: Place labels and instructions prominently to ensure they are easily seen by handlers. Climate Considerations Environmental conditions can affect the durability of corrugated boxes. Moisture Resistance: In humid conditions, consider using a moisture barrier such as a wax or plastic coating to protect the box. Temperature Fluctuations: Be aware that extreme temperatures can weaken the adhesive bonds in corrugated boxes. Regular Testing and Quality Checks Conduct regular testing to ensure the boxes meet your durability standards. Drop and Compression Tests: Regularly perform these tests to evaluate the box’s ability to withstand shocks and stacking pressures. Continuous Improvement: Use the test results to make ongoing improvements to your packaging strategy. If you are interested in maximizing the durability of your corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts