Stock Packaging

We supply businesses with a wide selection of essential packaging, shipping, and warehouse supplies. Get any standard packaging product by dimension or style from boxes, tubes, tapes, labels, and more. If you are unsure on what type of packaging you will need, then contact us for an expert consultation.

Stock packaging refers to pre-made, ready-to-ship packaging solutions like corrugated boxes, mailers, and protective materials that are designed to meet a wide range of standard needs across shipping, retail, and storage. Unlike custom packaging, stock options offer quick availability and reliable protection without the need for extensive design or production time, making them ideal for businesses needing efficient, high-quality solutions with fast lead times.

At Brown Packaging, we focus on providing durable, performance-driven stock packaging that supports our clients’ operational needs. Our stock products are sourced to ensure consistent quality and cost-effectiveness, offering a practical solution to keep operations running smoothly and on schedule. With an emphasis on reliability, we help our clients quickly access packaging solutions that meet their specific needs while maintaining quality across every order.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about custom packaging by reading our blog posts on new and trending topics.

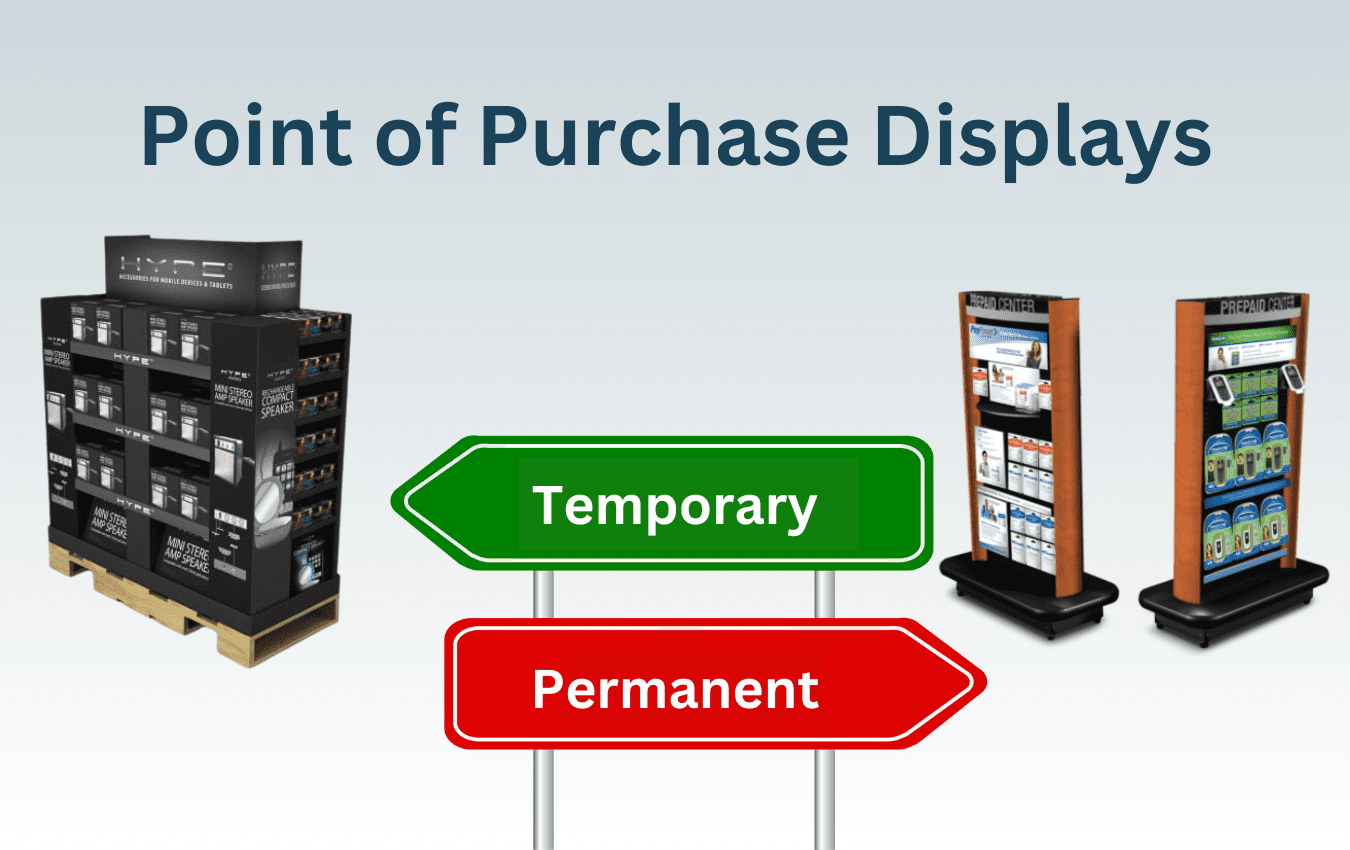

In the intricate world of retail, Point-of-Purchase (POP) displays play a critical role in influencing consumer decisions and driving sales. When it comes to choosing between temporary and permanent POP displays, retailers face a crucial decision that can significantly impact their marketing strategy and brand visibility. Each option comes with its own set of advantages and drawbacks, making it essential to understand the pros and cons of both approaches. Temporary POP Displays Pros Flexibility: Temporary displays are ideal for short-term promotions, seasonal campaigns, or product launches. They can be quickly set up and removed, allowing retailers to adapt to changing marketing strategies. Cost-Effective: These displays often require lower upfront costs, making them suitable for brands with budget constraints. Variety: Temporary displays come in various shapes, sizes, and materials, providing room for creativity and experimentation. Cons Limited Durability: As the name suggests, temporary displays are not built for long-term use and may not withstand heavy wear and tear. Brand Consistency: Achieving consistent branding can be challenging across various temporary displays, potentially affecting brand recognition. Environmental Impact: Frequent replacement of temporary displays can contribute to waste and environmental concerns. Permanent POP Displays Pros Durability: Permanent displays are designed to withstand continuous use and are suitable for long-term campaigns. They offer a more robust solution that can last for years. Consistent Branding: Permanent displays offer a consistent brand image throughout the store, enhancing brand recognition and customer familiarity. Sustainability: While they may involve higher upfront costs, permanent displays can be more environmentally friendly in the long run due to their extended lifespan. Cons Higher Costs: Permanent displays often require a larger investment upfront, including design, manufacturing, and installation expenses. Limited Flexibility: Once installed, making changes to permanent displays can be challenging and costly. Space Considerations: Permanent displays require dedicated space within the store, limiting flexibility in layout changes. Making the Right Choice The decision between temporary and permanent POP displays ultimately depends on your specific goals, budget, and brand strategy. Temporary Displays Are Ideal When: You have short-term promotions or seasonal campaigns. You want to test different display concepts and measure their effectiveness. Budget constraints are a concern. You want to keep your displays fresh and engaging by frequently updating them. Permanent Displays Are Ideal When: You have a consistent brand message that you want to convey throughout the year. You’re looking for a long-term solution that offers durability and sustainability. You have the budget for upfront investment and are willing to commit to a more substantial display presence. You want to establish a strong and recognizable brand presence within the store. A Hybrid Approach In some cases, it may be beneficial to opt for a hybrid approach, combining both temporary and permanent displays to leverage the strengths of each. For instance, permanent displays can serve as the foundation, while temporary displays are used for specific promotions or new product launches. If you are interested in pop displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts

Rigid boxes, also known as set-up boxes, are high-quality packaging boxes that offer an unmatched level of durability and sturdiness. They are often used for luxury products like cosmetics, electronics, and other high-end products that require extra protection during shipping and handling. While rigid boxes are known for their superior quality, they can be more costly than alternatives. In this blog, we will explore why rigid boxes are more expensive than people think and what factors contribute to their higher cost. Why Rigid Boxes Are Costly Material Costs One of the primary reasons why rigid boxes are more expensive than alternatives is the cost of the materials used to make them. Unlike regular corrugated boxes, rigid boxes are made from thicker and sturdier materials, such as heavier gauge chipboard. These materials are more expensive than regular cardboard, and the thickness of the material increases the cost of the box further. In addition, rigid boxes often require additional materials, such as foam inserts or magnetic closures, which can increase the overall cost of the box. Production Rigid boxes require a more complicated manufacturing process than regular cardboard boxes. The production process involves several steps, including cutting, folding, gluing, and assembly, which require specialized machinery and skilled labor. The production process for rigid boxes is more time-consuming and requires more manual labor, which adds to the overall cost of the box. Customization Rigid boxes are often used for high-end products that require a unique and personalized packaging solution. Customization options like embossing, debossing, foil stamping, and printing can add to the cost of the box. The cost of customization depends on the complexity of the design, the number of colors used, and the printing method used. In addition, the cost of customization increases with the size of the box, making larger boxes more expensive to customize. Shipping Costs Rigid boxes are heavier and bulkier than regular cardboard boxes, which can increase the cost of shipping. The additional weight and size of the box can also affect the cost of storage and warehousing. Brand Value Finally, the brand value associated with rigid boxes can also add to the overall cost. Rigid boxes are often associated with high-end products and luxury brands, and the premium packaging can enhance the overall customer experience. While the cost of the box may be higher, the perceived value of the product is also higher, which can justify the increased cost. Minimum Order Quantity Rigid boxes are often custom-made, which means that there may be a minimum order quantity (MOQ) requirement. The MOQ can vary depending on the size, material, and customization options of the box. A higher MOQ can increase the overall cost of the box, especially if you don’t need a large quantity. Design Costs If you don’t have an existing packaging design, you may need to hire a graphic designer or packaging specialist to create a design that fits your brand and product. Design costs can add to the overall cost of the box, especially if you require a complex or detailed design. Storage and Warehousing Costs Rigid boxes are bulkier than regular cardboard boxes, which can affect the storage and warehousing costs. If you’re ordering a large quantity of rigid boxes, you may need to find additional storage space to keep them until they’re ready to be shipped. Storage and warehousing costs can add to the overall cost of the box, especially if you’re working with a tight budget. When Should You Invest in a Rigid Box? When it comes to packaging, choosing the right box for your product is crucial for its protection during shipping and handling, as well as for the overall customer experience. While rigid boxes may be more expensive than regular cardboard boxes, there are several instances when investing in a rigid box can be a worthwhile investment for your product. Here are some of the scenarios when you should consider investing in a rigid box: High-End Products If you’re selling high-end products like luxury cosmetics, electronics, or other premium products, a rigid box is an excellent investment to enhance the overall customer experience. Rigid boxes offer a premium and sophisticated look and feel, which can increase the perceived value of the product. Fragile or Heavy Products If your product is fragile or heavy, a rigid box can provide the necessary protection during shipping and handling. The thick and sturdy material of rigid boxes can prevent damage or breakage, which can save you money in the long run by reducing the number of damaged or returned products. Customization Needs If you want to create a unique and personalized packaging solution for your product, a rigid box is an excellent choice. Rigid boxes offer a variety of customization options, including embossing, debossing, foil stamping, and printing. These customization options can help you create a packaging design that reflects your brand and enhances the overall customer experience. Retail Display Needs If your product will be displayed in a retail store, a rigid box can provide a more professional and polished look than regular cardboard boxes. Rigid boxes are sturdy and can be customized with your brand’s logo and design, making them an excellent choice for retail displays. Reusability Rigid boxes are durable and can be reused, making them a sustainable choice for packaging. If you’re selling a product that has a long shelf life or can be repurposed, a rigid box can be a great investment, as customers are more likely to keep the box and reuse it for storage or other purposes. Product Differentiation Investing in a rigid box can help your product stand out on the shelf and differentiate it from competitors. By customizing your rigid box with unique design elements, such as embossing or foiling, you can create a packaging solution that reflects your brand and product and captures the attention of consumers. If you are interested in rigid boxes or more cost-effective alternatives for your product, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most

In today’s fast-paced world, protecting fragile and valuable items during transportation is of utmost importance. Whether it’s delicate electronics, intricate machinery, or even perishable goods, reliable and innovative protective packaging solutions are essential to ensure products reach their destination unharmed. Over the years, advancements in technology have revolutionized the field of protective packaging, offering improved safety, efficiency, and sustainability. In this blog, we will delve into some of the most exciting technology innovations in protective packaging and explore their potential to transform the industry. Smart Packaging The integration of smart technologies into packaging has brought about a paradigm shift in protective packaging. Sensors and embedded devices now enable real-time monitoring of various environmental conditions, including temperature, humidity, pressure, and even shock. This data helps companies identify potential risks and take proactive measures to prevent damage. For instance, pharmaceutical companies can monitor temperature-sensitive medications to ensure they remain within the required temperature range during transit. Furthermore, smart packaging can also provide end-to-end visibility, allowing customers and businesses to track their packages in real-time, enhancing security and peace of mind. Active Packaging Active packaging involves incorporating active substances or systems within packaging materials to extend the shelf life of perishable products. For instance, oxygen absorbers and moisture control packets help maintain the freshness of food items, reducing spoilage and waste. Similarly, antimicrobial packaging inhibits the growth of bacteria, ensuring the safety and longevity of medical supplies and food products. By actively interacting with the product or its environment, these packaging solutions actively contribute to preserving the quality and integrity of goods during storage and transportation. Eco-friendly Materials Sustainability is a key focus in the packaging industry, and protective packaging is no exception. Innovations in eco-friendly materials have paved the way for greener packaging solutions. Biodegradable and compostable packaging materials derived from renewable resources, such as plant-based plastics are gaining popularity. These materials offer comparable protective properties while significantly reducing the environmental impact associated with traditional packaging. Moreover, advancements in recycling technologies allow for the efficient reprocessing of packaging materials, promoting a circular economy. Shock-Resistant Packaging One of the primary challenges in protective packaging is mitigating the impact of shocks and vibrations during transportation. Recent technological advancements have led to the development of shock-resistant packaging materials with enhanced cushioning properties. For instance, advanced foam materials, such as polyethylene (PE or EPE) foams, polyurethane (PU) foams, and cross-linked foams, offer excellent shock absorption capabilities. Final Thoughts: Protective Packaging Technology Innovations Technology innovations in protective packaging have revolutionized the way we safeguard valuable and fragile items during transportation. From smart packaging with real-time monitoring capabilities to active packaging that extends the shelf life of perishable goods, these advancements have significantly improved safety and efficiency. Additionally, the adoption of eco-friendly materials and the development of shock-resistant packaging have contributed to reducing environmental impact and mitigating damage caused by transportation hazards. As technology continues to evolve, we can expect further advancements in protective packaging, ensuring the safe and secure delivery of products in the future. If you are interested in protective packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts