Home » Shipping Protection 101: How to Use Corrugated Edge Protectors

Shipping Protection 101: How to Use Corrugated Edge Protectors

When you ship items, you run the risk of damaging them during transit. Even with careful handling, packages can bump into each other and sustain damage. That’s why it’s crucial to take measures to protect your packages during shipping. One of the easiest and most effective ways to do this is by using corrugated edge protectors.

Corrugated edge protectors add an extra layer of protection to the edges and corners of your packages, preventing them from getting damaged during shipping. In addition to using edge protectors, you can also choose to use stretch film to further secure your package and prevent damage. While stretch film is optional, it can be especially useful for packages with irregular shapes or multiple items.

7 Steps to Using Corrugated Edge Protectors

In this guide, we’ll take you through the steps of using corrugated edge protectors, with the option of using stretch film, to protect your packages during shipping.

Step 1: Determine the size of the edge protectors you need

The first step in using corrugated edge protectors is to measure the item you’re shipping. Determine the length, width, and thickness of the packaging material you’ll be using. You’ll need to choose edge protectors that are slightly larger than the item to ensure adequate protection.

Additionally, consider the weight and fragility of the item. Heavier items may require thicker edge protectors, while fragile items may need extra padding or cushioning.

Step 2: Choose the right type of edge protector

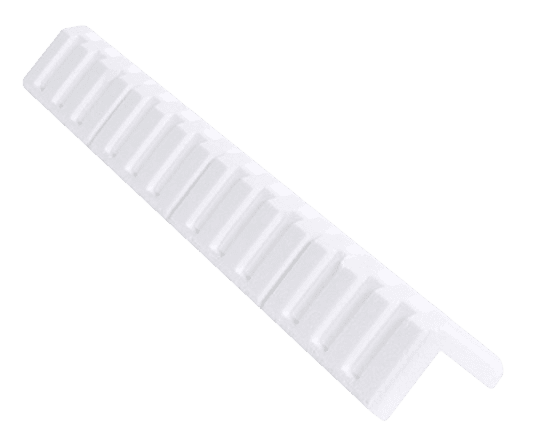

There are several types of edge protectors to choose from, including L-shaped, U-shaped, and C-shaped protectors. L-shaped protectors are best for protecting corners, while U-shaped protectors are designed to wrap around the edge of an item. C-shaped protectors are ideal for cylindrical items like pipes or tubes.

You’ll also need to choose the right material for the edge protectors. Cardboard, plastic, and foam are common options. Each material has its own strengths and weaknesses, so choose the one that best suits your needs.

Step 3: Cut the edge protectors to size

Use a utility knife or box cutter to cut the edge protectors to the appropriate size. Cut them long enough to cover the entire edge or corner of the item, and wide enough to provide adequate protection. For L-shaped protectors, cut the corner at a 45-degree angle to ensure a snug fit. U-shaped protectors should be cut at a 90-degree angle.

Step 4: Secure the edge protectors to the item

Use tape or adhesive to secure the edge protectors to the cardboard or other packaging material. Apply the tape or adhesive to both the edge protector and the packaging material to ensure a secure hold. Make sure the edge protectors are properly aligned to provide adequate protection.

Step 5: Add additional protection if needed

For fragile items or those with irregular shapes, consider adding additional protection. Bubble wrap, packing peanuts, or other protective materials can help cushion the item and prevent damage during shipping.

If you choose to use stretch film, wrap it tightly around the package, ensuring that it’s snug but not so tight that it damages the package or its contents. Choose the appropriate type of stretch film for your specific needs, as different types have varying levels of strength and stretchability.

Step 6: Label and ship the package

Label your package with any necessary shipping information, such as the destination address and tracking number. Add a “Fragile” or “Handle with Care” label if necessary. Use a permanent marker or label maker to create clear, legible labels and place them in a visible location on the package.

Step 7: Monitor the shipment

Keep track of the shipment by utilizing the tracking information provided by the carrier. Regularly check the status and location of your package to ensure its progressing smoothly towards its destination.

If you encounter any delays or issues during the shipment, promptly contact the carrier to address the problem. In cases of damaged or lost items, you may need to file a claim with the carrier to seek compensation or resolution.

Summary: Edge Protectors

By following these steps, you can effectively protect your packages during shipping using corrugated edge protectors and optional stretch film. Start by measuring your item and selecting the appropriate size and type of edge protectors. Cut them to size and securely attach them to your package. If necessary, add extra protection such as bubble wrap. Optionally, wrap the package with stretch film for added security, particularly for irregularly shaped or multiple-item packages. Properly label the package and monitor the shipment using tracking information.

Remember, taking the time to properly protect your packages will help minimize the risk of damage during shipping. Whether you’re sending fragile items or packages with irregular shapes, using corrugated edge protectors and optional stretch film will provide an extra layer of protection and peace of mind. Happy shipping!

If you are interested in edge protectors or corner boards, then partner with Brown Packaging today to get started.

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss,

Home » Shipping Protection 101: How to Use Corrugated Edge Protectors

In the world of packaging, the way a corrugated box is sealed and closed is as important as the box itself. The right type of

In today’s fast-paced world, protecting fragile and valuable items during transportation is of utmost importance. Whether it’s delicate electronics, intricate machinery, or even perishable goods,

Packaging inserts, also known as inlays or box partitions, play a critical role in the packaging industry by enhancing product protection, presentation, and customer experience.