Home » Roll End Tuck Tops, Cherry Locks, and Dust Flaps Explained

Roll End Tuck Tops, Cherry Locks, and Dust Flaps Explained

The world of packaging design is rich with innovative solutions that cater to various product needs. Among these, Roll End Tuck Tops (RETT), Cherry Locks, and Dust Flaps are noteworthy for their unique functionalities and benefits. This blog post aims to shed light on these specific packaging features, explaining how each of them works and the value they add to product packaging.

Roll End Tuck Tops (RETT)

RETT boxes are a popular choice in the packaging industry, known for their strength and user-friendly design.

- Design Features: RETT boxes are characterized by their roll-end sides and a top flap that tucks into the front of the box. This design provides enhanced strength and durability, making it ideal for heavier items.

- Ease of Assembly: A major advantage of RETT boxes is their ease of assembly, as they do not require additional adhesives or tapes. This feature not only simplifies the packing process but also offers a seamless unboxing experience.

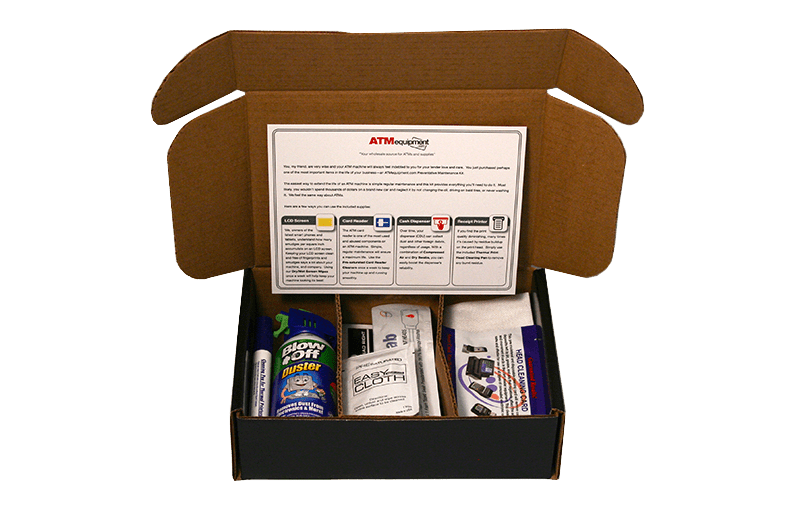

- Applications: RETT boxes are versatile and can be used for a wide range of products, including retail items, subscription boxes, and e-commerce shipments. Their robust structure ensures product safety during transit, while their sleek appearance enhances the visual appeal.

Cherry Locks

Cherry Locks are designed for added security and strength, ensuring that the contents of a box remain secure.

- Locking Mechanism: The distinctive feature of Cherry Locks is the interlocking tabs that securely close the box without the need for glue or tape. This mechanism provides a firm lock, safeguarding the contents inside.

- Versatility in Use: Cherry Locks can be incorporated into various box styles, making them a suitable choice for diverse packaging needs. Their secure locking system is particularly beneficial for shipping and handling.

- User Experience: The secure closure of Cherry Locks, combined with the ease of opening, makes them an attractive choice for enhancing the customer experience.

Dust Flaps

Dust Flaps serve an important function in protecting the product from external elements.

- Purpose and Function: Positioned on the sides of the box’s top panels, Dust Flaps fold inward to prevent dust, dirt, and other contaminants from entering the package.

- Protection and Cleanliness: While they may seem like a minor addition, Dust Flaps are essential in ensuring product cleanliness, especially for items that are sensitive to dirt and dust.

- Wide Applicability: Dust Flaps are particularly valuable in industries where maintaining product integrity is critical, such as in food packaging, pharmaceuticals, and electronics.

If you are interested in RETT boxes with dust flaps and/or cherry locks, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Roll End Tuck Tops, Cherry Locks, and Dust Flaps Explained

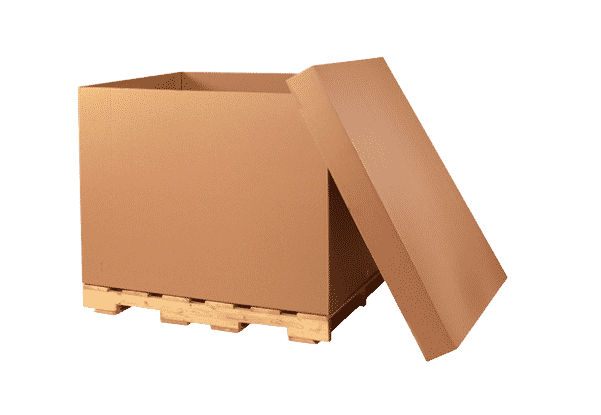

A Half Slotted Container (HSC) is a specific type of corrugated box known for its robustness, versatility, and open-top design. These features make HSCs ideal

Corrugated Boxes are exposed to many different circumstances during packing, shipping and storage. Ensuring that your corrugated packaging is protecting your product fully is important.

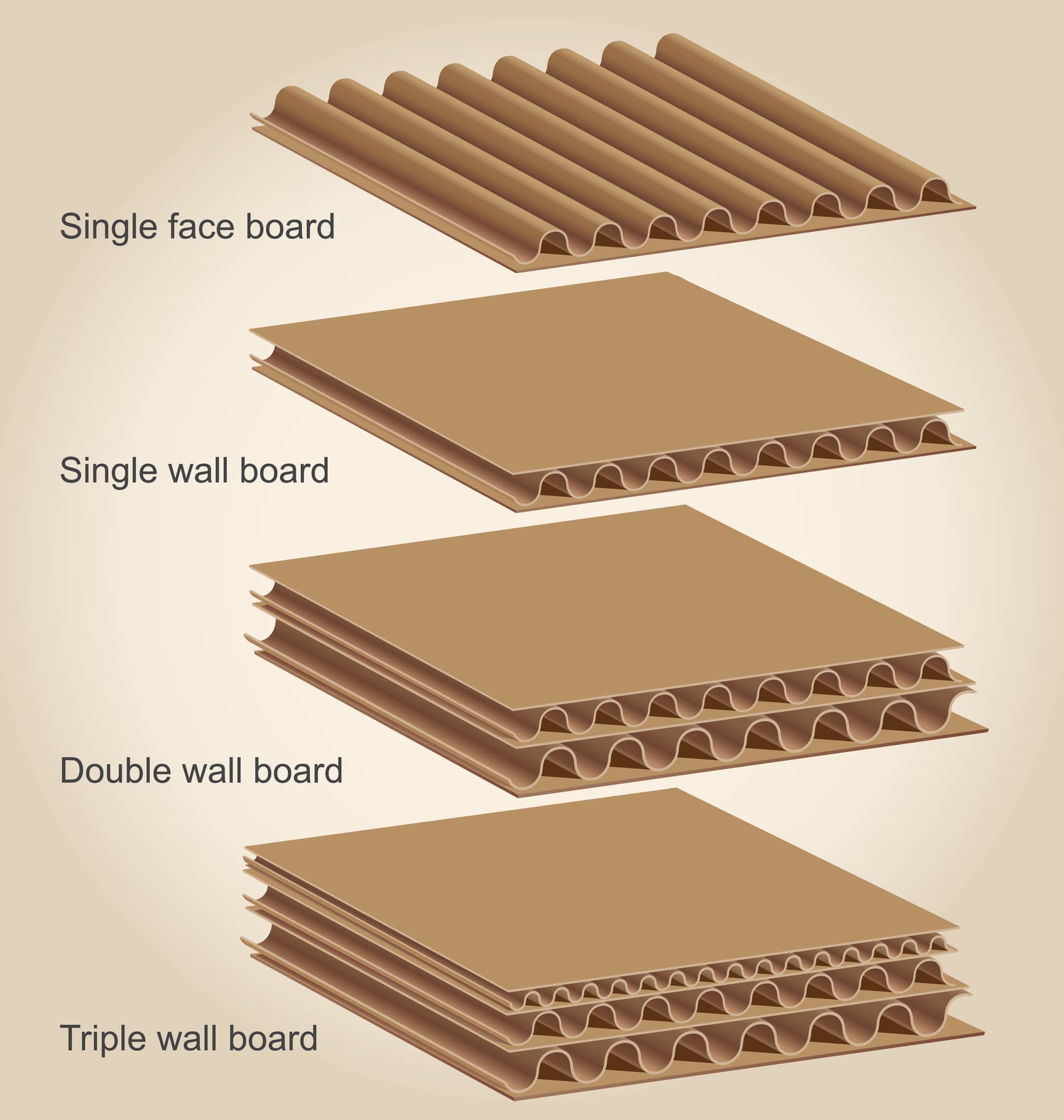

When it comes to packaging, boxes made from a material called corrugated board are among the most commonly used types today. Corrugated board consists of