Home » Roll End Tuck Top (RETT) Box Explained: Uses & Benefits

Roll End Tuck Top (RETT) Box Explained: Uses & Benefits

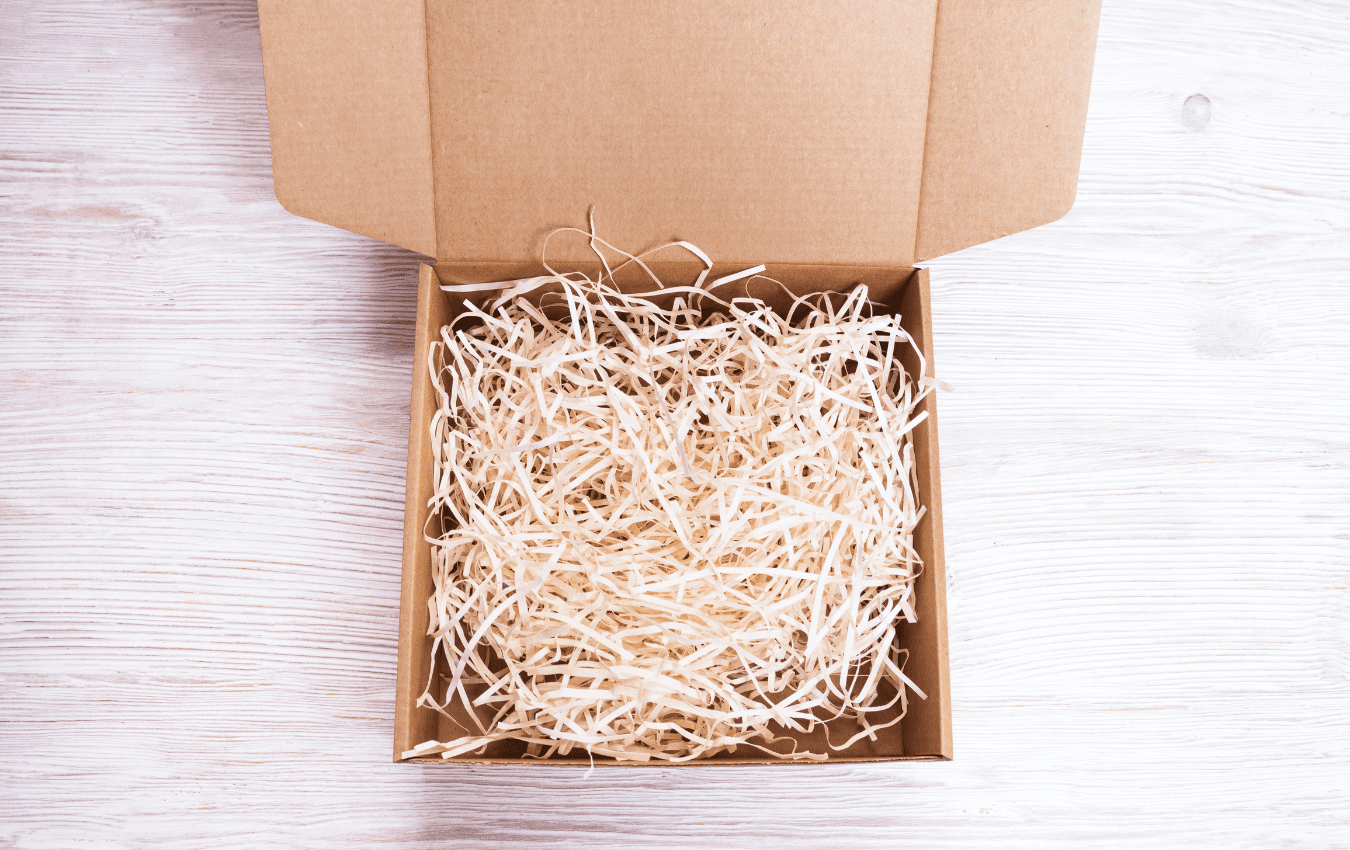

RETT boxes are a popular type of corrugated mailer used by the retail and ecommerce industry to ship and display products. These boxes are designed to open and close by tucking the top piece inside of the box, kind of like opening a treasure chest. Many businesses decide to package their products in RETT boxes because of its excellent unboxing experience, structural strength, branding and product protection.

You will learn that roll end tuck top boxes are used in a variety of applications and can bring plenty of benefits and added value to your product.

Roll End Tuck Top Applications

Many retail and ecommerce businesses that sell medical, electronic, industrial, cosmetic and consumer good products tend to use RETT boxes. Even though these boxes are typically used for shipping, they can be used inside a store. To help you get a better understanding of RETT boxes here are a list of everyday applications:

- Subscription Boxes

- Sales Kits Containers

- Product Box

- Shipping Box

- Pastry Boxes

- Shelf Storage Containers

These boxes are generally used to package small and medium sized products by themselves or together with other products/pieces. Depending on your product may warrant you to seek custom options such as the boxes’ shape and size.

Inserts and trays can be used to hold objects in place to improve product protection and accessibility of the product for end users. Inserts available for RETT boxes include chipboard, corrugated, thermoform and foam materials.

Roll End Tuck Top Customization and Options

RETT boxes are highly customizable and versatile, which is why they are used to package many different products. For example, graphics and finishes can be added to your packaging to help enhance your branding, message, product information, images, and other content. In addition, there are many different print options for corrugated boxes such as flexo, litho and digital print that can be applied to both the inside and/or outside. Graphics and finishes can be added.

RETT boxes can be customized with features such as:

- Dust Flaps: blocks dust from entering.

- Lift Tab: A tab cut on the edge of the box, which helps users access the boxes content.

- Catalog Lock: an insert tab that holds the box close.

- Tear Strip: prevents product tampering and helps users open the box.

- Adhesive Strip: double sided tape that is commonly used to seal the box.

- Thumb Notch: enables easier access and opening of the box.

Other ways to customize your RETT box can be based on the strength required to support and protect your product effectively. Sustainable options are available depending on your package supplier, if you are interested in sustainable options, then contact Brown Packaging.

Roll End Tuck Top Benefits

There are many advantages to package your product in a roll end tuck top mailer such as:

- Made with strong and durable materials

- Easy for fulfilment (kitting)

- Easy for consumers to open

- Versatile in applications

- Flexibility in printing and customization options

- Material and cost efficient compared to alternative mailers such as roll end tuck top with dust flap (RETTDF) and roll end cherry lock (RECL), also known as roll end front tuck (REFT)

- Re-closable

- Two-sided print or single sided print available

- Sustainable – recyclable and reusable

Roll End Tuck Top Variations & Alternatives

RETT boxes may not always be the best option for you despite all these benefits. However, there are variations of RETT that you might be interested in if you are looking for additional packaging security. For example, you might want to consider RECL, RETTDF, roll end cherry locks and dust flaps (RECLDF) also known as REFT with dust flaps for extra security.

RECLDF

RETTDF

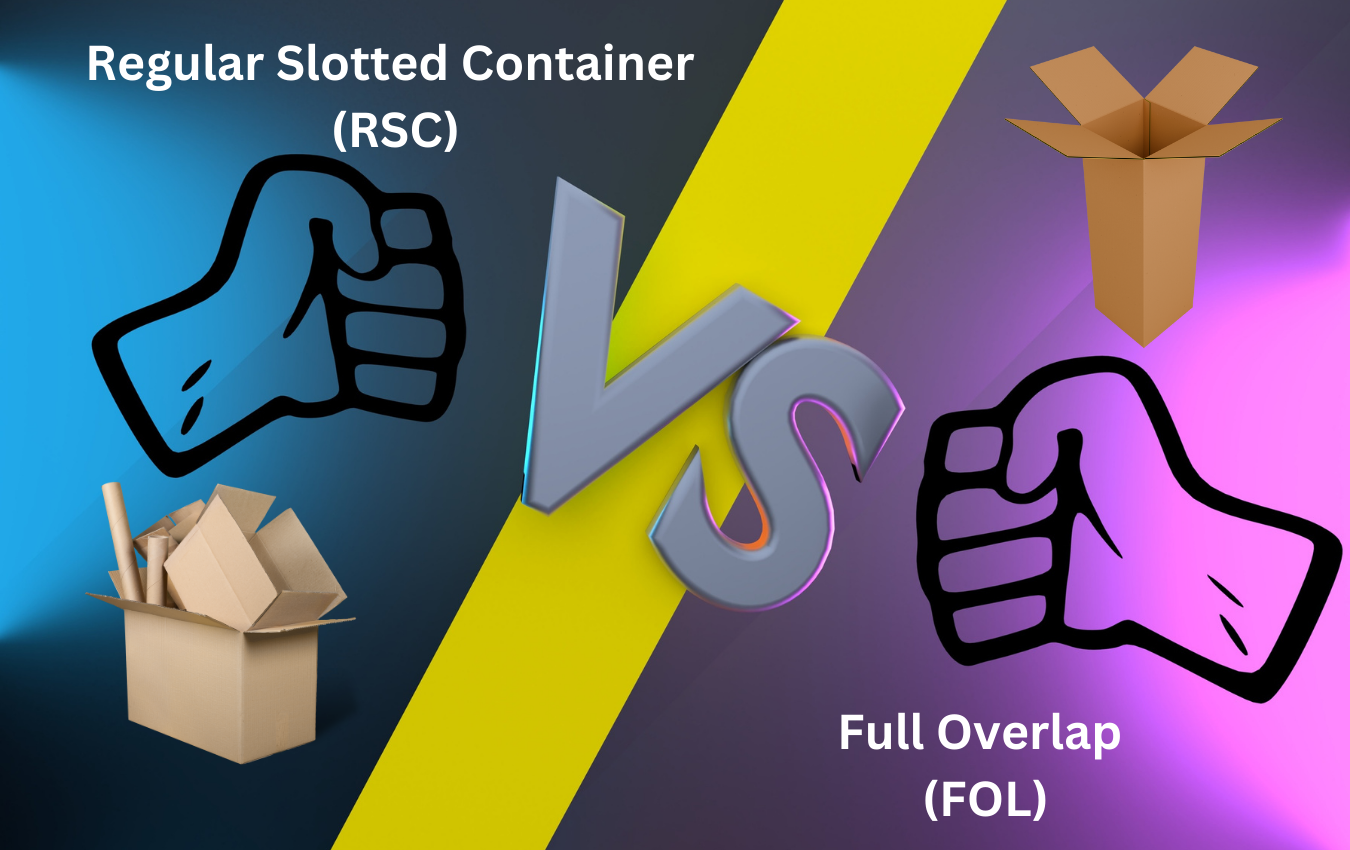

Cheaper alternatives that may work with your application include pouches, folding cartons and poly mailers. For large products: you may want to consider regular slotted containers (RSC) or full overlap (FOL). If you want a more luxury approach, then we recommend rigid boxes.

Gusseted Pouch

Rigid Box

Where Can You Purchase RETT Boxes?

Not all packaging suppliers can provide you with custom RETT boxes. You may want to consider whether you want a custom or stock roll end tuck top box, as availability will vary from supplier to supplier. In addition, stock RETT boxes are not available in any size, as they are limited to the most common sizes.

If you are interested in either custom or stock mailer boxes, then contact Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Roll End Tuck Top (RETT) Box Explained: Uses & Benefits

Choosing the right foam density isn’t about “soft” versus “hard” — it’s about controlling shock transmission and matching the foam’s cushioning curve to the product’s

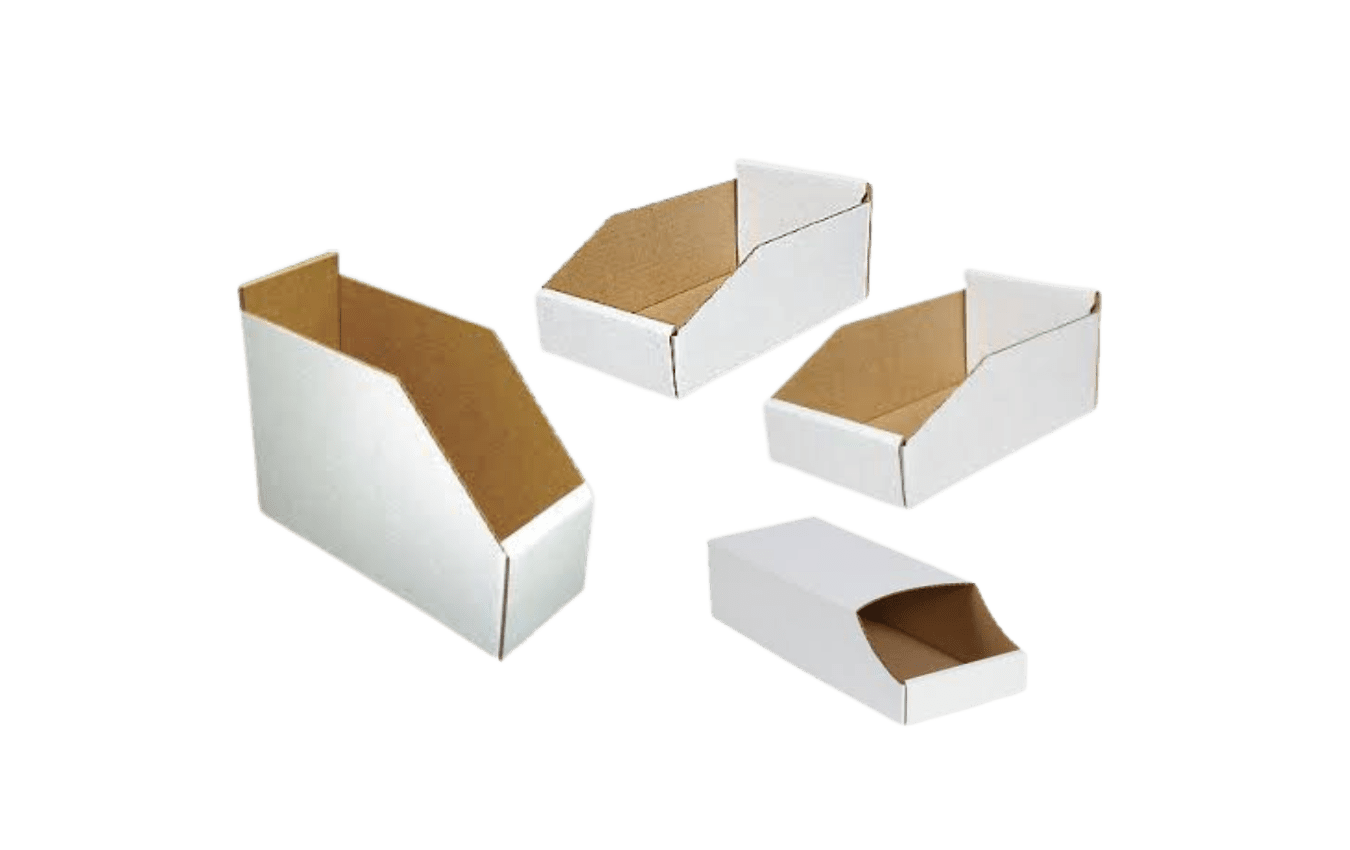

In the sprawling universe of storage solutions, corrugated bin boxes often go unnoticed. These unsung heroes of organization have a lot to offer when it

When it comes to packaging solutions, corrugated boxes offer versatility and protection. Among the common corrugated box styles are the Regular Slotted Container (RSC) box