Home » Recycling and Upcycling Corrugated Boxes

Recycling and Upcycling Corrugated Boxes

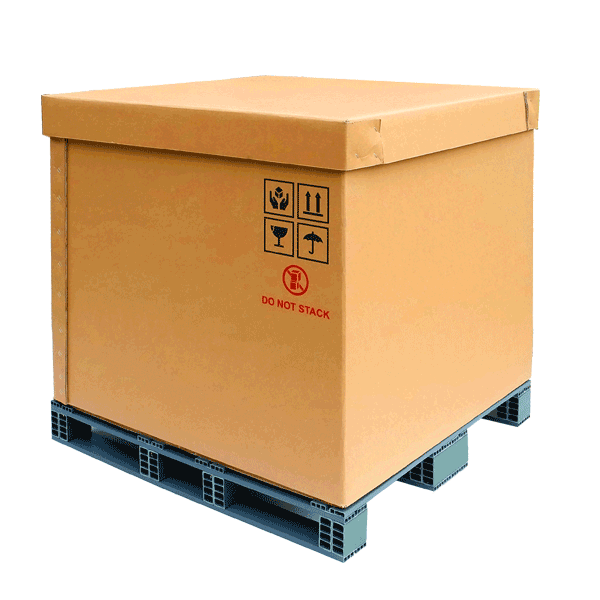

When you unwrap that eagerly awaited online order, or when the supermarket shipments arrive, corrugated boxes are almost always involved. With the increase in e-commerce and global shipments, the use of these boxes has surged. The question then arises: what do we do with all these boxes? The answer lies in the twin practices of recycling and upcycling. Let’s delve deep into the world of corrugated boxes, examining their environmental impact and how we can give them a second (or third) life.

The Environmental Impact of Corrugated Boxes

The Production Cost: The production of corrugated boxes requires vast amounts of energy and water. Trees are felled, processed, and transformed into paper pulp, which then becomes the corrugated cardboard we’re familiar with. While it’s true that many companies have started sourcing wood from sustainable forests, the process still consumes valuable resources.

Landfills: When discarded improperly, these boxes contribute to the already mounting waste in landfills. Although corrugated cardboard decomposes faster than plastics, it still takes between 3 to 8 months for it to fully break down. This decomposition can produce methane, a greenhouse gas 25 times more potent than carbon dioxide.

Carbon Footprint: From the transport of raw materials to the box’s final delivery, the entire lifecycle of a corrugated box adds to the carbon footprint. This doesn’t even account for the transportation of discarded boxes to landfills.

Recycling Corrugated Boxes

Recycling is the process of converting waste materials back into new products to prevent waste of potentially useful materials.

The Recycling Process: Once the boxes reach the recycling facility, they’re sorted, cleaned, and broken down into paper pulp again. This pulp is then used to create new cardboard or paper products.

The Benefits:

- Resource Conservation: Recycling corrugated boxes means fewer trees are cut down to produce new boxes.

- Energy Saving: Producing items from recycled materials consumes less energy compared to starting from scratch.

- Reduced Pollution: Fewer raw materials being processed means reduced air and water pollution.

Upcycling Corrugated Boxes

Upcycling, in contrast to recycling, involves creatively repurposing or redesigning waste materials into products of better quality or for better environmental value.

Creative Uses for Old Boxes:

- Storage Bins: Decorate and reinforce old boxes to create stylish storage solutions for your home.

- Wall Art: Cut out patterns or shapes from boxes, paint them, and fix them onto walls for an eco-friendly décor solution.

- Garden Solutions: Use flattened cardboard as a weed barrier in gardens. It’s biodegradable and effective.

- Kids’ Playhouse: Combine several boxes to create playhouses, castles, or forts for kids. They can even join in, painting and decorating.

- Pet Toys: Shape the cardboard into toys or scratch pads for pets. Cats, for instance, love corrugated cardboard scratchers.

- Gift Tags: Cut out small pieces, paint or decorate them, and use them as tags for gifts.

- Organizers: Craft compartmentalized trays or organizers for drawers or desks.

In conclusion, while corrugated boxes do pose an environmental challenge, through conscious efforts in recycling and upcycling, we can mitigate their impact. The journey of a box doesn’t have to end once its primary purpose is fulfilled. With a touch of creativity and environmental awareness, we can ensure that the story of every box is both inspiring and green.

If you are interested in corrugated boxes, then partner with Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Home » Recycling and Upcycling Corrugated Boxes

In the world of shipping and storage, the term “Gaylord box” often comes up, especially in industries that deal with bulk materials and goods. But

Packaging is not merely a practical aspect of shipping; it’s also a statement about your brand’s commitment to quality and protection. When it comes to

In the world of logistics and e-commerce, shipping is a critical aspect of business operations. Among the various packaging options, the Regular Slotted Container (RSC)