Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

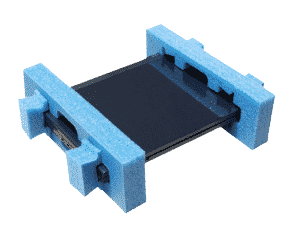

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

Pouch packaging continues to gain traction across industries due to its versatility, lightweight nature, and eco-friendly potential. In 2025, brands will adopt innovative and sustainable pouch solutions to meet consumer expectations for convenience and environmental responsibility. Below are the top pouch packaging trends expected to shape the market in 2025: Sustainable Materials Flexible and Refillable Pouches Eco-Friendly Printing Technologies Lightweight and Space-Saving Designs Customizable Branding and Personalization Recyclable and Compostable Pouches Resealable and Reusable Features Smart and Interactive Packaging Monomaterial Pouch Designs Cost-Effective Pouch Solutions Sustainable Materials Pouch packaging in 2025 will see an increased shift toward sustainable, eco-friendly materials. Pouches made from plant-based plastics, biodegradable films, and recycled materials will dominate as brands seek to reduce their environmental impact while offering packaging that’s durable and reliable. Flexible and Refillable Pouches Refillable pouches will become more common, especially in industries like personal care and cleaning products. These pouches offer a convenient, eco-friendly alternative to single-use containers, allowing consumers to refill and reuse the packaging multiple times, reducing plastic waste significantly. Eco-Friendly Printing Technologies In 2025, brands will turn to more sustainable printing methods for pouch packaging. This includes water-based inks, digital printing, and other low-impact printing technologies that reduce harmful emissions and chemical waste. These solutions also offer high-quality graphics that enhance the visual appeal of the pouch without compromising sustainability. Lightweight and Space-Saving Designs Pouches are already popular for their lightweight and space-saving advantages, and this trend will continue into 2025. The reduced material usage in pouches helps lower shipping costs and carbon emissions, making them an eco-conscious choice for businesses looking to streamline their packaging while maintaining product integrity. Customizable Branding and Personalization Customization will continue to play a key role in pouch packaging, with brands offering unique designs that enhance consumer experiences. From limited-edition graphics to personalized messages, digital printing allows for flexible design changes that meet consumer preferences for personalized, eye-catching packaging. Recyclable and Compostable Pouches Pouches made from recyclable and compostable materials will become standard in 2025 as companies strive to eliminate non-recyclable plastics. Advances in monomaterial technology will make pouches easier to recycle, while compostable alternatives will provide eco-friendly disposal options for consumers. Resealable and Reusable Features Resealable pouches continue to be a popular choice due to their convenience and ability to maintain product freshness. In 2025, more brands will adopt these features to meet consumer demand for packaging that extends product life while also offering the potential for reuse, adding both convenience and environmental benefits. Smart and Interactive Packaging The integration of smart technology, such as QR codes or NFC chips, in pouch packaging will continue to rise in 2025. This technology allows consumers to engage with the product through interactive content, track the product’s journey, or access detailed sustainability information. It also helps brands communicate transparency and build consumer trust. Monomaterial Pouch Designs Monomaterial pouches, made from a single type of plastic, will be more prevalent due to their recyclability. The simplified composition of monomaterial pouches makes them easier to process in recycling systems, reducing waste and improving the sustainability of flexible packaging. Cost-Effective Pouch Solutions Cost efficiency will remain a driving factor for pouch packaging, with businesses seeking ways to balance sustainability and affordability. Advances in manufacturing technology will allow brands to produce pouches at lower costs while maintaining the high-quality features consumers expect, such as resealability, durability, and design flexibility. Pouch packaging is evolving to meet both sustainability goals and consumer convenience. In 2025, brands that embrace these trends will be better positioned to deliver eco-friendly, cost-effective, and innovative packaging solutions to a market increasingly focused on sustainability and customization. If you’re interested in pouches for 2025, whether they are custom or stock, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Pouches Facebook Twitter LinkedIn Pinterest Relevant Posts

Tariffs proposed for 2025 are set to reshape the packaging industry, driving changes in costs, sourcing, and lead times. For packaging buyers, one of the most critical adjustments will be navigating disruptions in lead times, as tariffs incentivize a shift toward domestic sourcing. Understanding how these changes will affect procurement timelines is essential for maintaining smooth operations in the evolving marketplace. The Role of Tariffs in Extending Lead Times The proposed tariffs aim to reduce reliance on imported packaging materials and finished products. While this promotes domestic manufacturing, it also introduces challenges: Supply Chain Realignment: A sudden increase in demand for U.S.-sourced packaging can strain domestic suppliers, leading to extended production schedules. Limited Domestic Capacity: Many U.S. packaging manufacturers operate at near-full capacity, and scaling up to meet demand will take time. Customs Delays: For businesses still reliant on imports, the additional administrative processes associated with tariffs could delay shipments further. Factors Contributing to Longer Lead Times Supply Chain Bottlenecks As businesses pivot to domestic suppliers, these manufacturers may struggle to meet the surge in demand. The result could be production backlogs, delaying order fulfillment. Increased Competition for Materials Materials like paperboard, corrugated cardboard, and plastics are expected to see heightened demand domestically. With limited availability, buyers may face longer waits for procurement. Import Delays and Costs For companies that continue importing, tariffs create new challenges: Administrative Processes: Tariff-related documentation and compliance checks can slow customs clearance. Reduced Import Volume: Higher costs from tariffs may lead suppliers to reduce shipments, further limiting availability. Industries Most Affected by Lead Time Changes Certain sectors within the packaging industry are particularly vulnerable to lead time extensions: Custom Packaging: Projects requiring unique designs or specialized materials often involve longer production cycles, which could be further extended by domestic supplier backlogs. High-Volume Orders: Bulk orders for e-commerce, retail, or manufacturing sectors may experience delays due to limited production capacity. Sustainable Packaging: Eco-friendly materials like recycled kraft paper may face higher demand, lengthening procurement timelines. Proactive Strategies to Manage Lead Times To mitigate the impact of tariffs on lead times, packaging buyers can adopt several strategies: Partner with Multiple Suppliers Diversifying your supplier base can reduce reliance on any single manufacturer, providing flexibility if one supplier experiences delays. Plan Ahead and Stockpile Extended lead times require more precise forecasting and inventory management. Stockpiling essential materials when possible can help prevent disruptions. Leverage Local Sourcing While domestic suppliers may face initial challenges, working with local manufacturers can eliminate the delays associated with customs processes and long-distance shipping. Optimize Packaging Design Reducing complexity in packaging designs can shorten production times. For instance, shifting from multi-component packaging to simpler, mono-material designs can streamline manufacturing. Utilize Advanced Planning Tools Digital tools for demand forecasting, order tracking, and supply chain management can provide real-time insights, enabling better planning and quicker response to disruptions. Opportunities Amid Challenges Despite the potential for longer lead times, tariffs could drive positive changes for the packaging industry over the long term: Investment in Domestic Infrastructure: Increased demand for U.S.-sourced packaging may lead to expansion and modernization of domestic manufacturing facilities, ultimately reducing lead times. Stronger Buyer-Supplier Relationships: Closer collaboration between buyers and domestic suppliers can foster innovation and improve lead times over time. Enhanced Supply Chain Resilience: Reduced reliance on global supply chains mitigates risks from international disruptions, such as shipping delays or geopolitical tensions. What Packaging Buyers Need to Know To thrive in this changing environment, packaging buyers must prioritize proactive planning and supplier collaboration. By understanding how tariffs influence lead times and adapting strategies accordingly, businesses can maintain operational efficiency and avoid costly delays. In Summary: Tariffs are set to create challenges in packaging lead times, but with the right preparation and strategies, businesses can adapt effectively. Focus on building flexible supply chains, optimizing packaging designs, and leveraging local sourcing to minimize disruption and ensure success in 2025 and beyond. If you are interested in limiting the impact of tariffs on your packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As 2025 approaches, the U.S. packaging industry faces significant shifts due to proposed tariffs aimed at encouraging domestic sourcing. These changes could reshape supply chains, cost structures, and market dynamics, presenting both challenges and opportunities for businesses. Below, we explore how tariffs could influence the packaging industry and what buyers need to know to navigate this evolving landscape. Tariffs and Domestic Sourcing: A New Era for Packaging? The proposed tariffs reflect a push to reduce reliance on imported goods, favoring American-made products. For the packaging industry, this means a potential increase in demand for domestically sourced raw materials and finished packaging products. While this shift aligns with broader goals of economic independence, it could also disrupt current supply chains. Key Implications: Increased Costs for Imported Materials: Tariffs on materials like paperboard, plastics, and aluminum will likely drive up costs for companies reliant on foreign suppliers. Demand for U.S.-Based Manufacturing: Businesses may pivot to local suppliers, benefiting domestic manufacturers but potentially creating supply bottlenecks in the short term. Longer Lead Times: Transitioning to domestic sources may extend lead times as the industry adjusts to meet heightened demand. Material Costs: A Major Concern for Buyers One of the most immediate effects of tariffs will be the cost of raw materials. Common packaging materials like corrugated cardboard, flexible plastics, and metalized films are often sourced globally to balance quality and affordability. Tariffs could significantly alter these dynamics. For Example: Corrugated Boxes: The cost of imported linerboard and medium could increase, pushing up prices for corrugated packaging. Plastic Packaging: Tariffs on polyethylene and other polymers may lead to higher costs for flexible pouches and shrink films. Metal Packaging: Aluminum tariffs could impact beverage cans and other metal containers, with costs being passed on to buyers. Packaging buyers should anticipate these changes and consider strategies to manage costs, such as renegotiating supplier contracts or exploring alternative materials. Opportunities for Sustainable Packaging As tariffs promote domestic production, there’s an opportunity to incorporate sustainability into the equation. Many U.S.-based manufacturers prioritize eco-friendly practices, aligning with growing consumer and corporate demand for sustainable packaging. Potential Benefits: Local Sourcing Reduces Carbon Footprint: Shorter transportation distances for materials can reduce greenhouse gas emissions. Investment in Green Technologies: U.S. manufacturers are increasingly adopting renewable energy and recycling processes, offering buyers eco-friendly options. Compliance with Domestic Standards: Working with U.S. suppliers ensures adherence to stringent environmental regulations, supporting sustainability goals. Adaptation Strategies for Packaging Buyers To stay competitive in this new landscape, packaging buyers should proactively adapt to these changes. Here are some strategies to consider: Diversify Your Supplier Base Establish relationships with multiple domestic suppliers to reduce dependence on any single source and mitigate potential disruptions. Explore Alternative Materials Consider using materials less impacted by tariffs, such as kraft paper or recycled substrates, which may be more readily available domestically. Optimize Packaging Design Reducing material usage through innovative design can offset increased costs. For instance, lightweighting or reducing void space in packaging can lead to significant savings. Invest in Forecasting and Inventory Management Improved demand forecasting and stockpiling essential materials can help mitigate the effects of longer lead times and fluctuating prices. Long-Term Impacts on the Packaging Industry While tariffs may initially present challenges, they also have the potential to strengthen the domestic packaging industry over time. Increased investment in local production capacity, innovation in sustainable materials, and closer collaboration between buyers and suppliers could lead to a more resilient industry. Looking Ahead: Technological Advancements: Domestic manufacturers may leverage automation and digital tools to boost efficiency and offset higher labor costs. Stronger Supply Chains: Local sourcing reduces vulnerability to global disruptions, such as those seen during the COVID-19 pandemic. Competitive Advantages: Companies that adapt quickly may find themselves better positioned to meet evolving market demands. Preparing for the Future Tariffs will undoubtedly shape the U.S. packaging industry in 2025 and beyond. By understanding their potential impacts and adopting proactive strategies, packaging buyers can navigate these changes effectively while positioning their businesses for success. The road ahead may require adjustments, but with careful planning and a commitment to innovation, the packaging industry can thrive in this new environment. If you are interested in optimizing the cost efficiency and performance of your packaging for 2025, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As companies assess their packaging supply chain strategies, many are debating between U.S. and Chinese packaging suppliers in 2025. While China has long been known for lower production costs, recent trends such as rising tariffs, increased shipping costs, and supply chain risks have made domestic U.S. manufacturing a more attractive and stable option. Understanding the key differences between these two sourcing locations can help businesses make informed decisions. Comparing U.S. and China Packaging Suppliers Key Factors Driving Packaging Sourcing Decisions Tariffs and Trade Policies Tariffs have significantly impacted packaging imports from China, with high duties on corrugated boxes, paperboard, and other packaging materials making U.S.-based manufacturing more competitive. The ongoing trade tensions between the U.S. and China create uncertainty, while domestic suppliers avoid these risks, offering a more stable pricing model without import duties. Cost Considerations China’s packaging production costs are still generally lower due to cheaper labor and large-scale manufacturing capabilities. However, added expenses such as tariffs, international shipping fees, freight surcharges, and customs duties have narrowed the price gap between Chinese and U.S. suppliers. Many businesses now find that domestic production provides a more predictable and cost-effective long-term solution. Supply Chain Reliability and Lead Times U.S. Suppliers: Shorter lead times, faster domestic shipping, and reduced risk of international disruptions. China Suppliers: Long-distance shipping introduces delays, port congestion, and higher freight costs, making inventory planning more challenging. Winner? U.S. suppliers offer better supply chain stability, reducing the risks of global disruptions that have plagued businesses in recent years. Quality Control and Compliance The U.S. enforces strict quality standards and regulatory compliance for packaging, ensuring higher material consistency and safety requirements. While China offers high-volume production, quality control can vary, and businesses must factor in oversight costs, third-party inspections, and the risk of substandard materials. Intellectual Property Protection One of the growing concerns with sourcing packaging from China is the risk of intellectual property (IP) infringement. U.S.-based suppliers offer stronger protections for proprietary designs, branding elements, and custom packaging innovations, reducing the risk of unauthorized reproductions. Customization and Branding Companies requiring custom-sized boxes, high-end printing, or specialty coatings often find U.S. suppliers more flexible and responsive. China’s packaging manufacturers can handle large-scale production but may lack the ability to quickly adjust custom orders or meet fast-changing branding demands. Final Thoughts: Which Option is Best for Your Business? Choose U.S. Packaging Suppliers if you prioritize supply chain reliability, faster lead times, tariff-free sourcing, and stronger quality control. Choose China Packaging Suppliers if your focus is lower upfront costs and large-scale production, and you’re prepared to manage longer lead times, tariffs, and quality control challenges. As packaging sourcing strategies evolve in 2025, businesses must weigh costs, supply chain risks, and quality considerations carefully. Looking for a reliable U.S. packaging supplier? Contact Brown Packaging today to discuss custom solutions tailored to your business needs! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As companies evaluate their packaging supply chains, many are choosing U.S. packaging suppliers over overseas alternatives. While domestic suppliers offer advantages such as faster lead times and stronger quality control, they also come with higher costs compared to some international options. Below, we break down the key pros and cons of working with U.S. packaging suppliers to help businesses make informed sourcing decisions. Is a U.S. Packaging Supplier the Right Choice for Your Business? Pros of U.S. Packaging Suppliers Faster Lead Times & Supply Chain Reliability One of the biggest advantages of sourcing packaging domestically is the shorter lead times. Without the need for overseas shipping, companies benefit from: Quicker turnaround on orders More predictable delivery schedules Reduced risk of supply chain disruptions (e.g., port congestion, global shipping delays) Tariff-Free & Cost Predictability With ongoing trade tensions, import tariffs on packaging materials from countries like China have made international sourcing more expensive. U.S. suppliers eliminate these risks, offering: Stable pricing without unexpected tariff hikes Lower overall logistics costs compared to international shipping fees Easier cost forecasting for long-term contracts Higher Quality Control & Compliance U.S. manufacturers adhere to strict regulatory standards for industries such as food, pharmaceuticals, and medical devices. Businesses benefit from: Consistent material quality and structural integrity Easier oversight of manufacturing processes Reduced risk of non-compliant or defective packaging Easier Communication & Collaboration Working with a domestic supplier means fewer language barriers and time zone differences, making it easier to: Adjust custom orders quickly Resolve issues in real-time Collaborate on branding, design, and structural innovations Intellectual Property Protection Unlike some overseas markets where intellectual property (IP) theft is a concern, U.S. suppliers offer: Greater legal protections for custom packaging designs Reduced risk of counterfeit packaging entering the market Stronger confidentiality agreements for proprietary packaging solutions Cons of U.S. Packaging Suppliers Higher Production Costs While the U.S. provides high-quality packaging, domestic production comes at a higher cost due to: Increased labor wages compared to countries like China and Mexico Higher raw material costs More expensive energy and operational costs Limited Economies of Scale for Some Products International suppliers, particularly in China, specialize in mass production at lower costs. U.S. suppliers may face: Higher per-unit costs for large-volume orders Fewer ultra-low-cost packaging options Less flexibility for high-volume, budget-driven businesses Potentially Higher Minimum Order Quantities (MOQs) Some U.S. manufacturers have higher MOQs, requiring businesses to place larger orders upfront. This can create: Increased storage and warehousing needs Higher initial investment for packaging inventory Less flexibility for small businesses or startups Final Thoughts: Should You Choose a U.S. Packaging Supplier? U.S. packaging suppliers offer strong advantages in quality, speed, and reliability, but businesses must weigh these against higher production costs and potential MOQ requirements. If your company values supply chain security, compliance, and premium customization, domestic sourcing is often the best choice. Looking for a reliable U.S. packaging supplier? Contact Brown Packaging today to explore custom solutions for your business needs. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts