Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

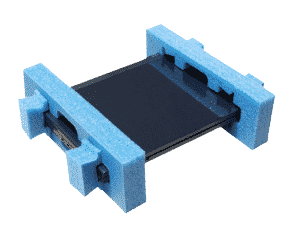

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

As tariffs take effect in 2025 to promote domestic sourcing, the packaging industry in the United States is set to experience notable cost changes. While the intent is to strengthen domestic production, these tariffs will impact the cost of materials, manufacturing, and logistics for packaging buyers. This blog explores how tariffs could influence packaging costs and offers neutral, practical insights for buyers to prepare. The Connection Between Tariffs and Packaging Costs Tariffs on imported goods are designed to encourage businesses to source materials and products domestically. While this shift can support U.S.-based manufacturing, it also leads to increased costs for certain types of packaging. Key Cost Drivers: Tariff-Driven Material Costs: Materials like corrugated fiberboard, plastics, and metals often rely on global supply chains. With added tariffs, the cost of importing these materials increases significantly. Labor and Production Costs: Domestic manufacturing typically involves higher labor and operational costs compared to international suppliers, contributing to overall price hikes. Supply Chain Adjustments: Transitioning from international to domestic sources may create temporary inefficiencies as suppliers and manufacturers adjust to new demand patterns. Impacts on Packaging Buyers Increased Procurement Costs Buyers will see higher costs for imported packaging materials and products. These increased expenses could stretch budgets, particularly for industries with high packaging needs, such as e-commerce, food and beverage, and retail. Examples of Affected Packaging: Corrugated boxes made from imported linerboard or medium. Flexible plastic packaging reliant on imported polymers. Aluminum packaging for food and beverage containers. Budget Reallocations Higher packaging costs may force buyers to reconsider how they allocate their budgets. For some, this could mean reducing spending in other areas, while others may need to evaluate their product pricing to offset rising expenses. Complex Pricing Dynamics Suppliers may pass the increased costs of tariffs onto buyers, creating ripple effects across the supply chain. Buyers should be prepared to navigate fluctuating prices and plan for potential cost variability. Opportunities for Cost Management Though tariffs pose challenges, packaging buyers can adopt strategies to minimize their impact: Collaborate with Domestic Suppliers Establishing strong relationships with U.S.-based manufacturers can help mitigate tariff-related costs. Domestic suppliers may offer competitive pricing and eliminate the need for international shipping and customs fees. Explore Alternative Materials Buyers can investigate cost-effective material options, such as: Recycled Content: Utilizing recycled kraft paper or corrugated material. Mono-Material Solutions: Simplifying material types in packaging to reduce complexity and cost. Optimize Packaging Design Design changes can reduce material usage and lower costs. For example: Lightweighting to use less material without compromising functionality. Streamlining packaging dimensions to minimize waste and transportation expenses. Leverage Technology and Data Investing in tools for demand forecasting and inventory management can help buyers optimize purchasing decisions, avoiding overstock or emergency orders that may carry premium costs. Consider Volume Discounts For companies with high packaging needs, negotiating bulk purchase agreements can help offset higher per-unit costs. Long-Term Outlook on Packaging Costs While tariffs may initially drive up packaging costs, they also encourage domestic manufacturing and innovation. Over time, this could stabilize supply chains and foster advancements in cost-efficient packaging solutions. Potential Positive Outcomes: Strengthened Domestic Infrastructure: Investment in U.S.-based production facilities may reduce reliance on international suppliers, leading to more stable pricing over the long term. Focus on Sustainable Practices: Domestic manufacturers often emphasize sustainability, potentially aligning with buyers’ eco-friendly goals. How Packaging Buyers Can Prepare Packaging buyers can take several steps to adapt to cost changes driven by tariffs: Conduct thorough cost analyses to understand the impact on your operations. Diversify your supplier base to include both domestic and international options. Plan procurement schedules strategically to avoid delays or additional costs. By staying informed and proactive, buyers can navigate the evolving market while minimizing disruptions. In Summary Tariffs in 2025 are set to influence packaging costs through increased material expenses, labor costs, and supply chain adjustments. While these changes present challenges, buyers can manage the impact by adopting strategic sourcing practices, optimizing packaging designs, and collaborating with domestic suppliers. By preparing for these shifts, businesses can remain competitive in a dynamic market. If you are interested in controlling your packaging cost or making proper preparations to your packaging for tariffs in 2025, then partner with Brown Packaging today for assistance. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Custom corrugated boxes, owing to their versatility, durability, and eco-friendliness, have become a crucial tool for businesses seeking to maximize their packaging appeal. In today’s competitive market, where every detail counts, a bespoke print on your corrugated box can be the differentiating factor that elevates your brand above the rest. Understanding Corrugated Boxes Before diving into the printing methods, let’s understand the foundation – the corrugated box itself. Crafted from corrugated cardboard which consists of a fluted layer nestled between two flat liners, these boxes are renowned for their strength. This unique structure not only ensures product safety but also provides an optimal surface for various print methods. The Case for Custom Printing So, why should one invest in custom printing? Beyond the obvious aesthetic appeal, custom printed boxes offer functional advantages. They facilitate smoother inventory management, as labels and prints assist in quick content identification. Additionally, a custom design brings a touch of professionalism, subtly signaling to clients and partners that you care about every aspect of your business, down to the boxes you use. And let’s not forget promotion; the surface of your box can be a canvas for marketing messages or spotlight promotions. Flexographic Printing Flexographic printing, often compared to traditional letterpress printing, stands out for its adaptability to print on a wide range of substrates. This method uses flexible relief plates that transfer ink onto the box’s surface. When you have large-volume orders but wish to keep costs in check, flexographic printing offers a reliable solution. Its strength lies in producing large batches efficiently, and the prints dry relatively quickly. Digital Printing Evocative of the common home inkjet printers but on a much grander scale, digital printing promises precision. Perfect for businesses looking to place smaller orders or those desiring intricately detailed graphics, this method doesn’t necessitate printing plates, enabling quicker turnaround times. The real allure of digital printing, however, is its impeccable accuracy, ensuring each design is replicated to perfection. Litho Laminating and Single Face Printing Litho laminating is akin to artistry in the world of box printing. Here, a high-resolution printed paper sheet (the litho label) gets glued meticulously onto the corrugated material. It’s the go-to for businesses keen on delivering a retail experience that speaks of luxury and attention to detail. The resultant boxes often have a glossy, upscale appearance. Spot UV Printing A technique that’s both subtle and impactful, Spot UV printing introduces a tactile dimension to box printing. Specific areas are cured using UV light, giving them a glossy, raised appearance. This is not just about aesthetics; it’s a sensory experience, making logos or particular design features truly pop. Green Printing The print industry has been conscious of its environmental footprint, leading to the emergence of eco-friendly inks and coatings. Water-based inks, for instance, have become popular as they are significantly less harmful than their solvent-based counterparts. UV-curable inks are also gaining traction for being free from volatile organic compounds (VOCs). Biodegradable coatings, on the other hand, ensure that the environment doesn’t pay the price for our aesthetic pursuits. Designing for Print In the realm of print, understanding your audience remains paramount. Tailor your designs with your target demographic at the forefront of your mind. Consistency is key, so incorporate brand colors and motifs, ensuring that the box is an extension of your brand identity. Lastly, while it’s tempting to fill every inch with design elements, sometimes less truly is more. Effective use of white space can deliver a design that’s both impactful and elegant. In Conclusion Custom printing on corrugated boxes is that detail that can set you apart. Armed with knowledge about the diverse printing techniques available, you’re well-placed to make a decision that aligns with your brand’s ethos, aesthetic preferences, and budget. If you are interested in printed corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging is the first line of defense for your products, shielding them from the hazards they may encounter during storage, handling, and transportation. One of the most critical aspects of packaging is safeguarding it against physical damage. In this blog, we’ll delve into various strategies and best practices to help you protect your packaging from physical harm, ensuring that your products remain safe and intact. Understanding the Risks Before delving into protective measures, it’s crucial to understand the potential sources of physical damage that your packaging might face: Impact during Handling: Packages can be dropped, bumped, or mishandled during various stages of transportation and storage. Compression: Stacking heavy items or applying excessive pressure can lead to package deformation or crushing. Vibration: Prolonged exposure to vibrations, especially in long-distance shipping, can weaken packaging materials and affect their integrity. Sharp Objects: Sharp objects in the vicinity of packages can puncture or tear the packaging material. Protective Measures To safeguard your packaging from physical damage, consider the following protective measures: Material Selection: Choosing the right packaging material is paramount. Select materials known for their durability, strength, and resistance to physical damage. Reinforced Corners and Edges: Weak points in packaging are often the corners and edges. Reinforce these vulnerable areas with additional layers of material or protective corner guards to absorb impact and prevent crushing. Cushioning and Padding: Using cushioning materials like bubble wrap, foam inserts, or air pillows can provide a protective buffer against shocks and vibrations. Ensure that products are snugly cushioned inside the packaging. Stacking Strength: If stacking is a concern, design packaging with enhanced stacking strength. Reinforce the packaging structure to distribute weight evenly and minimize the risk of crushing. Inner Packaging Layers: For particularly fragile or sensitive items, consider adding inner packaging layers. These can include protective pouches, sleeves, or dividers to prevent product-to-product contact and potential damage. Impact Indicators: Use impact indicators or shock labels on packages. These devices can detect and record impacts during transportation, allowing you to identify and address any potential issues promptly. Testing and Quality Control: Implement rigorous testing procedures to ensure the packaging can withstand expected impacts and stresses. Conduct drop tests, compression tests, and vibration tests to assess package durability. Customized Packaging Design: Tailor packaging designs to fit the specific requirements of your products. Avoid using oversized boxes, as this can lead to excessive movement and damage. Handling and Storage Guidelines: Provide clear instructions for handling and stacking packages. Train employees and partners involved in the packaging and transportation process to follow these guidelines diligently. Regular Evaluation and Improvement The protection of your packaging from physical damage is an ongoing process. Continuously assess your packaging solutions and gather feedback from transportation partners to identify any weaknesses or areas for improvement. Make necessary adjustments to enhance packaging resilience and ensure that your products arrive at their destination in optimal condition. By implementing these strategies and maintaining a proactive approach to packaging protection, you can significantly reduce the risk of physical damage to your products and enhance their overall quality and safety. If you are interested in safe and proper packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As businesses increasingly shift away from overseas suppliers, finding a reliable domestic packaging supplier in the USA has become a priority. Domestic suppliers offer shorter lead times, better quality control, and protection from tariffs and international shipping delays. However, identifying the right supplier requires strategic research and evaluation to ensure they meet your specific packaging needs. Key Steps to Finding a U.S. Packaging Supplier Define Your Packaging Requirements Before searching for a supplier, establish clear requirements based on: Packaging Type: Corrugated boxes, folding cartons, flexible packaging, etc. Customization Needs: Printing, coatings, branding, and structural design. Order Volume: Minimum order quantities (MOQs) and scalability for future growth. Industry Standards & Compliance: Food-grade, pharmaceutical, retail, or industrial packaging. Use Online Supplier Directories and Industry Networks Utilize trusted business directories and industry associations to locate reputable suppliers. Some useful resources include: Thomasnet.com – A leading directory of U.S. manufacturers and suppliers. Packaging World Supplier Database – A resource for finding packaging companies. National Association of Manufacturers (NAM) – A database of U.S. manufacturing companies. Trade Shows & Conferences – Events like Pack Expo provide opportunities to meet suppliers in person. Evaluate Supplier Capabilities and Reliability Once you have a list of potential suppliers, conduct thorough evaluations based on: Manufacturing Location & Capacity: Ensure the supplier has facilities within the U.S. and can handle your volume requirements. Lead Times & Logistics: Confirm turnaround times, delivery options, and warehouse locations. Certifications & Compliance: Look for ISO, FDA, FSC, or industry-specific certifications that align with your needs. Customer Reviews & Case Studies: Assess feedback from businesses in your industry. Request Samples and Quotes To ensure product quality, request physical samples before placing a bulk order. Compare multiple quotes for: Material Quality & Durability – Ensure the packaging meets protection standards. Printing & Customization Quality – Verify branding and finishing options. Pricing Transparency – Watch for hidden fees in setup, tooling, or freight costs. Build a Long-Term Partnership Choosing a packaging supplier isn’t just about pricing—it’s about finding a reliable long-term partner. A strong supplier relationship ensures consistent quality, priority service, and customized solutions as your business grows. Final Thoughts: Finding the Right U.S. Packaging Supplier The process of finding a domestic packaging supplier requires research, evaluation, and a clear understanding of your business needs. By prioritizing quality, responsiveness, and supply chain reliability, companies can secure the right partner for sustainable packaging success. Looking for a trusted U.S. packaging supplier? Contact Brown Packaging today to discuss customized solutions for your business. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As companies seek cost-effective and reliable packaging solutions, many are weighing the pros and cons of sourcing from U.S. vs. Mexican suppliers in 2025. While Mexico offers lower labor costs and proximity advantages over Asia, the U.S. provides stronger quality control, faster lead times, and protection against rising tariffs. With evolving trade policies, supply chain challenges, and shifting business priorities, companies must carefully evaluate which option best aligns with their needs. Comparing U.S. and Mexico Packaging Suppliers Key Factors Driving Packaging Sourcing Decisions Tariffs and Trade Policies Tariffs continue to play a major role in sourcing decisions. The U.S.-Mexico-Canada Agreement (USMCA) provides duty-free trade on many packaging materials, making Mexico an attractive alternative to overseas suppliers. However, uncertainty around future tariffs on imported goods and new border trade regulations could impact long-term cost predictability. Meanwhile, U.S. suppliers avoid tariff risks entirely, offering a more stable pricing structure. Cost Considerations Mexico’s lower labor and operational costs give it an advantage over U.S. suppliers when it comes to raw production pricing. However, hidden costs such as import duties, transportation, and customs delays can add unexpected expenses. The U.S. offers more predictable costs, particularly as rising international shipping rates and potential regulatory shifts affect cross-border trade. Supply Chain Efficiency and Lead Times U.S. Suppliers: Shorter lead times, faster domestic shipping, and just-in-time inventory solutions. Mexico Suppliers: Proximity to the U.S. reduces shipping time compared to overseas, but border delays and customs clearance can create unpredictability. Winner? U.S. suppliers generally provide faster and more reliable delivery for businesses needing quick turnaround times. Quality Control and Compliance The U.S. has strict quality standards and regulatory oversight, ensuring that packaging meets industry-specific requirements for food, pharmaceuticals, and industrial goods. While many Mexican manufacturers adhere to high standards, inconsistent oversight and variations in material quality can pose challenges for certain industries. Customization and Branding Advantages For companies needing custom-sized boxes, premium printing, or unique coatings, U.S. suppliers offer greater flexibility and quicker production adjustments. While Mexico can produce custom packaging, businesses may experience longer turnaround times due to distance and communication barriers. Final Thoughts: Which Option is Best for Your Business? Choose U.S. Packaging Suppliers if you prioritize faster lead times, stronger quality control, and tariff-free sourcing. Choose Mexico Packaging Suppliers if you’re focused on cost reduction and are willing to navigate potential trade and logistics complexities. As packaging supply chains continue to evolve in 2025, businesses must weigh the benefits and risks of each sourcing option carefully. Looking for a reliable U.S. packaging supplier? Contact Brown Packaging today for custom solutions tailored to your business needs! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts