Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

Full-Overlap (FOL) boxes are renowned for their structural integrity and robust design, making them a popular choice for packaging products that require extra protection during transit. In this detailed blog, we will delve into the features, functions, and customization options of Full-Overlap boxes, shedding light on why they are a go-to solution for businesses seeking secure and tailored packaging. Understanding Full-Overlap (FOL) Boxes Full-Overlap (FOL) boxes, as the name suggests, are characterized by their design, where the flaps on the top and bottom fully overlap when the box is closed. This unique feature distinguishes them from other box styles and contributes to their exceptional strength and protection. Key Features of Full-Overlap (FOL) Boxes Enhanced Protection: Full-Overlap boxes provide superior protection due to their overlapping flap design. This feature safeguards the contents from external impacts, moisture, and rough handling during shipping. Structural Integrity: The overlapping flaps enhance the structural integrity of the box, preventing it from collapsing or becoming deformed, even when stacked with other boxes. Secure Closure: FOL boxes feature a secure closure mechanism, typically using adhesive tape, glue, or staples, ensuring that the box remains sealed throughout the shipping process. Custom Sizing: Full-Overlap boxes can be custom-sized to fit specific product dimensions, minimizing excess space within the box and reducing the risk of damage due to movement during transit. Versatility: These boxes are versatile and suitable for various industries, including electronics, automotive, machinery, and delicate or heavy-duty items. Functions and Use Cases Shipping Fragile Items: Full-Overlap boxes are ideal for shipping fragile or delicate items, such as glassware, ceramics, electronics, and precision instruments, where protection against shocks and vibrations is crucial. Heavy-Duty Applications: Businesses that deal with heavy machinery, industrial equipment, or automotive parts often rely on FOL boxes to ensure the safe transit of their products. Retail Packaging: FOL boxes can be customized with branding and product information, making them suitable for retail packaging of high-end or premium items. Storage and Archive: Their robust construction also makes FOL boxes suitable for long-term storage and archiving of documents, records, and important materials. Customization Options Graphics and Branding: Full-Overlap boxes can be customized with printed graphics, logos, and branding to enhance their visual appeal and promote your brand. Interior Fittings: For added protection, you can include interior fittings such as foam inserts, partitions, or dividers to secure the contents within the box. Printing Options: Choose between digital, flexographic or lithographic printing methods to achieve the desired print quality and visual presentation. Material Selection: Select corrugated materials based on the level of protection required, whether single-wall or double-wall, and the flute type that suits your product’s fragility and weight. Conclusion Full-Overlap (FOL) boxes offer a winning combination of features, functions, and customization options that cater to a wide range of packaging needs. Their robust design, enhanced protection, and versatility make them a preferred choice for businesses looking to ensure the safe and secure transit of their products. Whether you need to protect fragile items, heavy-duty equipment, or showcase premium products, Full-Overlap boxes can be customized to meet your specific packaging requirements while leaving a lasting impression on your customers. If you are interested in full overlap corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Full Overlap Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

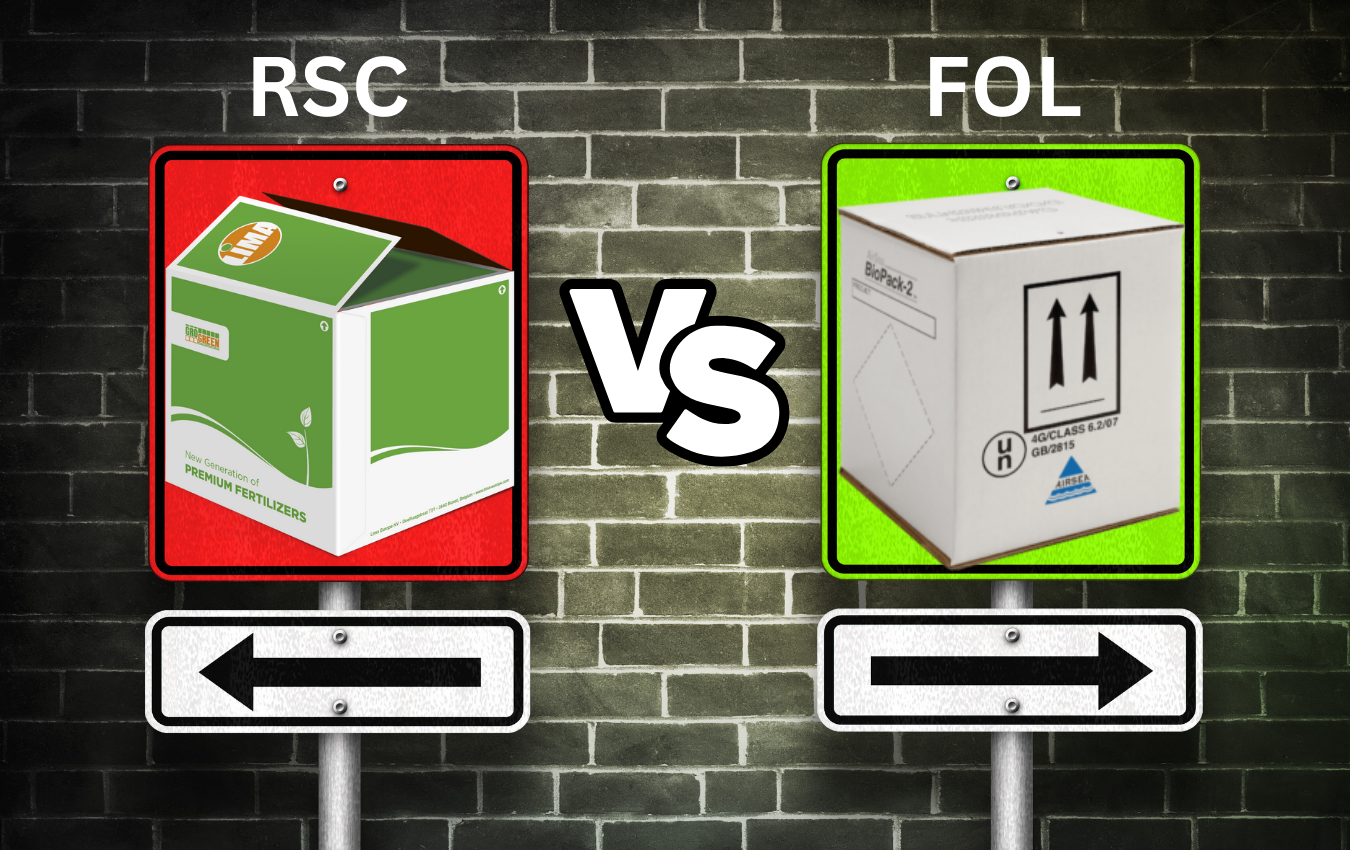

When it comes to packaging solutions, corrugated boxes offer versatility and protection. Among the common corrugated box styles are the Regular Slotted Container (RSC) box and the Full-Overlap (FOL) box. Each style caters to specific packaging needs, making them suitable for various applications. In this comparative analysis, we will explore the characteristics, use cases, advantages, and considerations of Corrugated RSC Boxes and Full-Overlap (FOL) Boxes to help you determine which is the right choice for your packaging requirements. What is a (RSC) Box? Regular Slotted Container (RSC) boxes are known for their simplicity and efficiency in design and production. They feature four flaps—two on the top and two on the bottom—that meet in the center when closed. RSC boxes are cost-effective and widely used across industries. What is a Full-Overlap (FOL) Box? Full-Overlap (FOL) boxes, in contrast, are designed with flaps that fully overlap when closed, providing added protection and structural integrity. These boxes excel in safeguarding products during transit, making them ideal for items that require extra strength and stability. A Comparative Analysis Design and Closure: Corrugated (RSC) Box: RSC boxes offer a straightforward design, making them easy to assemble and close with tape or adhesive. Closure involves folding the flaps on the top and bottom, taping or gluing to a secure seal. Full-Overlap (FOL) Box: FOL boxes feature overlapping flaps, enhancing structural integrity and security. The flaps provide additional protection and resistance to crushing, making FOL boxes ideal for fragile or heavy items. Protection and Strength: Corrugated (RSC) Box: RSC boxes offer standard protection and are suitable for a wide range of products. While they provide adequate strength, they may not be the best choice for heavy or delicate items. Full-Overlap (FOL) Box: FOL boxes excel in providing enhanced protection and structural integrity. They are ideal for shipping heavy, fragile or valuable items, including electronics, glassware, and machinery. Versatility: Corrugated (RSC) Box: RSC boxes are versatile and can be used for various products and industries. They are cost-effective and readily available in standard sizes. Full-Overlap (FOL) Box: FOL boxes are versatile as well but are often chosen for specific applications requiring superior protection. They may be slightly more expensive than RSC boxes due to their specialized design. Customization: Corrugated (RSC) Box: RSC boxes can be customized with printed graphics and branding, enhancing their visual appeal. Full-Overlap (FOL) Box: FOL boxes can also be customized with branding and graphics and are often used for premium or high-end products. Cost-Efficiency: Corrugated (RSC) Box: RSC boxes are generally more cost-effective due to their simpler design and ease of production. Full-Overlap (FOL) Box: FOL boxes may come at a slightly higher cost, primarily due to their enhanced protective features. Choosing the Right Box for Your Needs The choice between Corrugated RSC Boxes and Full-Overlap (FOL) Boxes hinges on your specific packaging requirements. Here are some considerations: If you need a cost-effective and versatile solution for standard products, Corrugated RSC Boxes are a practical choice. If you’re shipping fragile or valuable items, heavy machinery, or electronics, Full-Overlap (FOL) Boxes offer superior protection and structural integrity. Customization and branding are possible with both box styles, allowing you to create a unique packaging experience for your customers. If you are interested corrugated boxes like RSC, FOL and other styles, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

In the world of packaging, there’s a constant pursuit of innovation and improvement to ensure products are not only securely packaged but also easy to access. One such advancement in packaging technology is the incorporation of cherry locks in roll end tuck top (RETT) boxes. In this blog, we will delve into the intricacies of cherry locks, exploring their design, features, benefits, and the scenarios where they prove to be an invaluable addition to RETT boxes. Understanding Cherry Locks Cherry locks, also known as snap locks or friction locks, are a locking mechanism employed in packaging to secure the top flaps of boxes without the need for additional adhesives or tape. These locks are specifically designed to offer a secure closure while allowing for effortless and repeated opening, making them ideal for applications where ease of access is crucial. Here’s a closer look at their design and features: Benefits of Cherry Locks Cherry locks offer several advantages, making them a valuable addition to RETT boxes: Enhanced Security: Cherry locks provide a secure closure that prevents accidental opening during transit while deterring tampering or unauthorized access. Easy Access: The user-friendly design of cherry locks allows for quick and effortless opening, making them ideal for products that need to be accessed frequently, such as retail items or subscription boxes. Sustainability: Cherry locks contribute to sustainability efforts as they reduce the reliance on single-use adhesives and tapes, promoting eco-friendly packaging practices. These boxes can also be reused and repurposed. Cost Savings: While cherry locks may initially seem like a slightly higher investment, their reusability ultimately leads to cost savings by eliminating the need for additional sealing materials. Cherry Locks in Roll End Tuck Top Boxes Roll end tuck top boxes, with their inherent durability and versatility, are a perfect pairing for cherry locks. These boxes are constructed to provide a secure enclosure while allowing for easy customization and branding. When cherry locks are integrated into RETT boxes, they bring an added layer of security and convenience to the packaging solution. Scenarios for Using Cherry Locks in RETT Boxes Cherry locks are a versatile locking mechanism that can be employed in various industries and applications: Retail Packaging: RETT boxes with cherry locks are an excellent choice for retail packaging, ensuring that products remain secure on the shelves while allowing customers to open and inspect them easily. E-commerce: For e-commerce businesses, cherry locks enhance the security of shipped items while offering recipients a hassle-free unboxing experience. Subscription Boxes: Subscription box services benefit from cherry locks as they combine security with the convenience of repeated opening for subscribers. Electronics and Gadgets: Sensitive electronics and gadgets can be securely packaged with cherry locks, ensuring the contents are protected during shipping and readily accessible to users. Conclusion Cherry locks in roll end tuck top boxes represent a significant innovation in packaging design, offering the perfect balance between security and ease of access. Understanding the design, features, benefits, and potential applications of cherry locks can help businesses make informed choices when selecting packaging solutions. Whether you are in retail, e-commerce, or any other industry, the integration of cherry locks into RETT boxes can enhance your packaging strategy, providing a secure and user-friendly experience for both businesses and customers alike. If you are interested in roll end tuck top boxes with cherry locks, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Roll End Tuck Top Facebook Twitter LinkedIn Pinterest Relevant Posts

Before committing to a full production run, businesses often receive packaging samples to evaluate fit, functionality, print quality, and overall design. Whether it’s a digital sample (3D render) or a physical prototype, thoroughly assessing the sample ensures that the final packaging meets aesthetic, protective, and branding requirements. Evaluating a Digital Packaging Sample A digital sample, such as a 3D rendering or a dieline proof, is typically the first step in the approval process. It provides a visual representation of the packaging without producing a physical sample. What to Check in a Digital Sample: Structural Accuracy: Ensure the dieline dimensions match your specifications. Print & Branding Alignment: Confirm that logos, graphics, and text are correctly placed. Color Representation: Compare digital colors with your brand standards (note that digital colors may vary slightly from printed results). Typography & Readability: Check for font clarity, spacing, and legal text placement. Product Fit Estimation: Use the digital mockup to visualize how the product will fit inside the packaging. Next Steps for Digital Samples: Approve the design for a physical prototype if all elements look correct. Request modifications if there are misalignments, incorrect fonts, or sizing issues. Verify with a packaging expert to ensure compliance with industry regulations (especially for food, pharmaceuticals, or fragile products). Evaluating a Physical Packaging Sample Once the digital sample is approved, a physical prototype is produced. This allows for a hands-on review to confirm material quality, fit, and structural integrity. What to Check in a Physical Sample: Size & Fit: Ensure your product fits securely inside without excess movement. Material Durability: Assess the thickness, rigidity, and protective properties of the packaging. Printing & Finishing: Check for sharpness of logos, consistency of colors, and quality of coatings (matte, gloss, spot UV, etc.). Ease of Assembly: Verify that the packaging can be easily folded, sealed, or assembled as required. Structural Performance: Conduct drop tests, stacking tests, or compression tests if needed. Shipping & Storage Suitability: If your product requires long-distance shipping, assess whether additional protective inserts or reinforcements are needed. Next Steps for Physical Samples: Approve the sample for final production if all elements meet expectations. Request modifications if there are fit issues, material concerns, or branding inconsistencies. Test the sample in real-world conditions, such as placing it in a warehouse or shipping it to a test location. Making the Final Decision After evaluating the digital and physical samples, finalize your packaging decision by: Confirming with your team that the design meets branding, protection, and compliance requirements. Approving mass production once all issues are resolved. Coordinating with your supplier on lead times, material availability, and any final adjustments. Final Thoughts: Ensuring the Best Packaging for Your Product Receiving a packaging sample is a crucial step in avoiding costly mistakes and ensuring a seamless production process. By carefully evaluating both digital and physical samples, businesses can optimize product protection, branding impact, and customer experience. Need expert guidance in reviewing your packaging samples? Contact Brown Packaging today to ensure your final packaging is perfect before production! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Choosing the right corrugated box size is crucial for product protection, shipping efficiency, and cost savings. Whether you’re packing a single item or multiple products, knowing how much space you need inside the box ensures that products remain secure, undamaged, and optimized for storage and transportation. Step 1: Measure the Dimensions of Your Product(s) To determine how much space is required inside a corrugated box, start by measuring your product’s length, width, and height: Length: The longest side of the product. Width: The shorter side when placed flat. Height (Depth): The vertical measurement. For multiple products, consider how they will be arranged inside the box—whether stacked, side-by-side, or separated with inserts. Step 2: Add Space for Protection and Cushioning Corrugated boxes often require extra space to accommodate protective packaging materials like bubble wrap, foam inserts, or dividers. To ensure adequate protection: Add at least 1-2 inches around the product for cushioning. If using dividers for multiple items, consider the thickness of the divider material. For fragile items, factor in reinforced corners or inserts that prevent movement. Step 3: Determine the Optimal Box Style Different box styles offer varying levels of internal space efficiency. Common options include: Regular Slotted Container (RSC): Standard box with flaps for easy packing. Full Overlap Box: Adds extra strength for heavier products. Die-Cut Box: Custom-fitted designs for exact product sizing. Mailer Boxes: Compact and stylish for eCommerce shipments. Selecting the right style ensures that space is maximized while minimizing excess voids. Step 4: Consider Stacking and Shipping Constraints If your product needs to be stacked or palletized, box dimensions should align with standard pallet sizes to maximize storage efficiency. Additionally, consider: Weight distribution to prevent box crushing. Dimensional weight pricing from carriers like UPS and FedEx, where oversized boxes cost more to ship. Warehouse storage limitations for bulk packaging. Step 5: Test with a Sample Box Before committing to a final box size, order a prototype or sample box and perform a test fit. This helps verify: The fit and protection level of your product. Whether additional cushioning materials are needed. How easy the packaging is to assemble and seal. Final Thoughts: Optimizing Space in Your Corrugated Box Finding the right amount of space inside a corrugated box is a balance between product fit, protection, and shipping efficiency. By measuring accurately, accounting for protective materials, and testing with samples, businesses can reduce shipping costs, minimize damage, and improve packaging efficiency. Need help designing the perfect corrugated box for your products? Contact Brown Packaging today to find the best packaging solution for your needs! (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts