Brown Packaging

With over 30 years of experience, Brown Packaging has been a trusted partner for businesses of all sizes, providing custom and stock packaging solutions tailored to their needs. Our in-house services ensure personalized support, guiding you from concept to completion for a seamless experience. Whether you need innovative designs or sustainable options, we work with you every step of the way to deliver exceptional packaging results.

We offer a variety of custom packaging products and solutions to meet all your packaging needs in one place. You’ll work directly with a dedicated project specialist to customize your package according to your specifications, including branding, features, and design.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Our stock packaging products, from corrugated boxes to stretch film, offer a wide selection, including essentials like tape, edge protectors, labels, and more, with quick turnaround times to meet your packaging needs efficiently.

Optimize your packaging’s durability, security, branding, cost, unboxing experience and more.

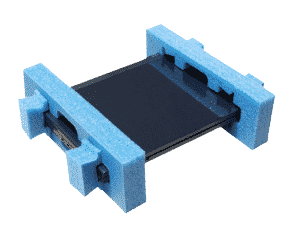

We build durable and efficient packaging for simple to the most complex products.

Sterilization, clean room and medical compliant packaging products and solutions.

We serve a wide variety of businesses including: pet, toy, cosmetic, electronic and more.

At Brown Packaging, we help our clients create unique packages that reflect their brand and produce results. As a result, we look to add as much value to your packaging experience and product as possible with our services.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

-

Structural Design

-

Graphic Design

-

Sampling & Prototyping

-

Contract Packaging & Fulfillment

-

Product & Material Testing

Optimize Your Packaging with Structural Design Services

Our structural design services optimize your packaging by enhancing durability and reducing material use, which leads to cost savings and increased sustainability. By focusing on efficient design, we help improve product protection, reduce shipping costs, and minimize environmental impact. These tailored solutions also boost your brand’s shelf presence, making your packaging both functional and attractive.

Elevate Your Packaging with Graphic Design Services

Our graphic design services enhance your packaging by creating visually appealing designs that strengthen branding and attract customer attention. By focusing on cohesive brand identity and impactful visuals, we ensure your products stand out on the shelf and resonate with your target audience. Thoughtfully designed packaging not only improves shelf appeal but also reinforces brand recognition and loyalty. Let us help you make a lasting impression with packaging that truly represents your brand.

Perfect Your Packaging with Sampling and Prototyping Services

Our sampling and prototyping services provide both digital and physical packaging samples, allowing you to see and feel your design before full production. We offer high-quality digital prints for precise visualization and physical samples to ensure the packaging meets your expectations in terms of design, fit, and function. This process helps you make informed decisions and refine your packaging to perfection before committing to large-scale production. Whether you need to test a concept or showcase a final design, our sampling and prototyping services ensure your packaging is ready for market.

Streamline Your Packaging with Fulfillment and Contract Services

Our fulfillment and contract packaging services offer comprehensive solutions, including assembly, kitting, pack-out displays, and co-packing. We handle every step of the process, ensuring your products are expertly assembled, packaged, and ready for distribution. Whether you need custom kitting, retail-ready displays, or efficient co-packing, our services are designed to streamline your operations and get your products to market quickly and efficiently. Trust us to manage the details, so you can focus on growing your business.

Ensure Quality with Product and Material Testing Services

Our product and material testing services ensure your packaging meets the highest standards of quality and durability. We rigorously test packaging materials to confirm they can withstand the demands of shipping, handling, and storage, protecting your products from damage. In addition, we assist in obtaining key certifications, such as ISTA and others, to ensure compliance with industry standards. By evaluating both the product and its packaging, we help you identify potential issues before they reach the market, ensuring reliability and customer satisfaction.

Our sustainable packaging products are designed to minimize environmental impact while maintaining top-notch quality and durability. Choose from a variety of eco-friendly materials, inks, prints and other customizable options to meet your sustainability goals.

At Brown Packaging, we specialize in providing innovative, fully customizable packaging solutions to meet all your business needs. With over 30 years of experience, we offer the capabilities of a large supplier while delivering personalized service and cost-efficient options. From concept to completion, we are committed to sustainability and offer a wide range of eco-friendly packaging solutions.

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Aaron Meneses went above and beyond servicing our company for our specific needs, and delivered on all his promises for the job. The outcome of the product went above our expectations and delivered ON TIME!

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

Full-Service Packaging

Get all your packaging needs from one supplier, guiding you from concept to completion.

Flexible Solutions

We offer packaging options to suit the needs of any brand and budget.

Expert Assistance

Work one on one with a dedicated project manager from concept to completion.

Compliant Solutions

Our packaging solutions meet both retailer requirements and government regulations.

Brown Packaging fulfilled many of our orders with competitive pricing and always provided a quick turn around time. Keith Thomas personally assisted me on several projects and helped walk me though all of the important ordering details. I will be contacting Keith again as new projects come my way!

If you need any assistance with your packaging or have a question, then contact us directly at request@brownpackaging.com or (714)300-0650. Learn more about packaging by reading our blog posts on new and trending topics.

The packaging sector has undergone a considerable transformation in the last few decades, with flexible packaging taking a significant lead. The shift is primarily due to its numerous benefits like lower costs, enhanced convenience, and sustainability, but one area where flexible packaging truly shines is in supply chain efficiency. Let’s delve deeper into understanding the role of flexible packaging in enhancing the efficiency of supply chains. What is Flexible Packaging? Flexible packaging refers to packages or materials that can easily change shape upon filling. These packaging forms often comprise plastics, paper, aluminum foils, or a combination of these materials. This can include anything from resealable food bags and pouches to flexible pharmaceutical packaging, illustrating the wide application spectrum of flexible packaging. Flexible Packaging and Supply Chain Efficiency: An Inextricable Link Storage and Transportation Efficiency One of the critical elements of supply chain management is ensuring the efficiency of storage and transportation. Flexible packaging dramatically improves these aspects. Its compact, lightweight nature reduces space requirements, enabling businesses to transport more products per shipment and utilize storage space more effectively. This improvement in freight efficiency not only reduces logistical costs but also curbs greenhouse gas emissions, promoting sustainability. Packaging and Unpacking Efficiency The ease of packing and unpacking offered by flexible packaging is another aspect contributing to supply chain efficiency. For instance, flexible packaging often incorporates features like zippers, spouts, and handles that simplify handling, opening, and resealing. This user-friendliness not only enhances consumer experiences but also aids in efficient product loading and unloading, saving time and labor costs in the supply chain. Waste Reduction and Environmental Impact Flexible packaging is generally lighter than its rigid counterparts, meaning it requires less material to produce. This attribute not only reduces waste generation at the production stage but also after consumer use, as there is less packaging material to discard. Moreover, many flexible packages are designed to be resealable, which can prolong product life and further reduce waste. This sustainability factor plays a critical role in promoting a green supply chain. Product Protection and Shelf Life Extension Flexible packaging materials are designed to provide optimal protection for products against environmental factors such as moisture, light, and air, ensuring product integrity and quality. This attribute reduces the risk of product spoilage or damage during transport or storage, leading to fewer losses in the supply chain. Many flexible packaging options also extend the shelf life of products, especially food items. This increased longevity reduces waste and the frequency of restocking, thus optimizing supply chain operations. Cost Savings By optimizing transportation and storage, reducing waste, and extending product shelf life, flexible packaging ultimately leads to substantial cost savings across the supply chain. These savings can then be passed on to the consumer, or reinvested into business growth and innovation. The Future of Flexible Packaging in Supply Chains With the continuous evolution of technology and consumer demands, the role of flexible packaging in supply chains is expected to grow even more significant. Innovations such as smart flexible packaging, which incorporates technologies like RFID tags and freshness sensors, will further enhance supply chain efficiency, transparency, and traceability. If you are interested in flexible packaging solutions, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Corrugated boxes are a ubiquitous part of our daily lives, used for packaging and shipping a wide variety of products. While they may seem simple on the surface, there is a remarkable blend of art and science involved in their design. A well-designed corrugated box ensures that products are protected during transit, minimizes material waste, and enhances the overall packaging experience. In this comprehensive guide, we will delve into the world of corrugated box design, exploring the artistry and scientific principles behind it. Understanding Corrugated Fiberboard Before diving into box design, it’s important to understand the material at its core: corrugated fiberboard. This versatile material consists of three layers: two flat linerboards on the outer surfaces and a wavy or fluted medium sandwiched between them. The fluted medium provides strength and rigidity, while the linerboards offer protection and a printable surface for branding and labeling. The Functionality of Corrugated Boxes The primary function of a corrugated box is to protect its contents during transit. However, the design must also consider factors such as cost-effectiveness, sustainability, and ease of handling. Let’s explore the various aspects that contribute to the functionality of corrugated boxes. Structural Integrity: The box must be structurally sound to withstand stacking, impact, and other stresses encountered during shipping. The arrangement and dimensions of flutes, the selection of linerboard thickness, and appropriate adhesive bonding all play a crucial role in ensuring the box’s strength. Stackability and Compression Strength: Corrugated boxes are often stacked on pallets during storage and transportation. A well-designed box should have sufficient compression strength to withstand the weight of other boxes stacked on top without collapsing or deforming. Cushioning and Protection: The box should provide adequate cushioning to protect the product from shocks, vibrations, and potential damage during transit. This can be achieved through the use of internal supports such as partitions, inserts, or foam padding. Ergonomics and Handling: The design should consider ease of handling for both workers and end-users. Factors like handholds, perforations for easy opening, and appropriate sizing contribute to a positive user experience. Sustainability: With growing environmental concerns, sustainable packaging is gaining prominence. Design considerations such as material selection, optimizing box dimensions to minimize waste, and incorporating recyclable or biodegradable materials contribute to a greener packaging solution. Box Design Considerations Designing a corrugated box involves a balance between functionality, aesthetics, and efficiency. Here are key considerations to keep in mind when embarking on the design process. Product Specifications: The dimensions, weight, fragility, and shape of the product being packaged influence the box design. It’s crucial to accurately measure and understand these specifications to ensure a well-fitted and protective box. Box Style Selection: Various box styles, such as regular slotted containers (RSCs), die-cut boxes, and telescopic boxes, cater to different product requirements. Choosing the appropriate box style influences factors such as ease of assembly, stackability, and presentation. Flute Selection: Corrugated fiberboard comes in different flute profiles, including A, B, C, E, and F. Each flute type offers specific strength and cushioning properties. Selecting the right flute profile based on the product’s fragility and weight is essential for optimal protection. Graphics and Branding: Corrugated boxes provide a valuable branding opportunity. Consider incorporating visually appealing graphics, logos, and other branding elements on the box surface to enhance the overall product presentation and create a memorable unboxing experience for the customers. Material Selection: The choice of linerboard material affects both the box’s strength and its visual appeal. Factors such as recycled content, virgin fibers, and the overall quality of the linerboard must be considered. Additionally, selecting the appropriate adhesive for bonding the layers is crucial for maintaining box integrity. Structural Design: The structural design of the box involves determining the dimensions, fluting orientation, and reinforcements required for optimal strength. Computer-aided design (CAD) software and structural analysis tools can aid in creating efficient and robust box designs. Testing and Prototyping: Before mass production, it’s essential to test and prototype the box design to ensure its functionality. Physical or virtual testing methods can evaluate the box’s performance under various conditions, such as drop tests, compression tests, and vibration tests. Supply Chain Considerations: The design should also take into account factors such as efficient storage, transportation, and stacking within the supply chain. Optimizing box dimensions to maximize space utilization and minimize transportation costs is an important consideration. Innovation in Corrugated Box Design The world of corrugated box design is constantly evolving, driven by advancements in technology and changing consumer demands. Innovations in this field aim to enhance functionality, sustainability, and user experience. Here are a few notable innovations in corrugated box design: E-commerce Packaging Solutions: With the exponential growth of online shopping, e-commerce packaging has become a focus of innovation. Designs that offer easy opening, customized printing for branding, and secure protection for products are key considerations in this area. Smart Packaging: Integration of technology into corrugated boxes opens up possibilities for smart packaging solutions. RFID tags, QR codes, or other tracking mechanisms can provide real-time information about the package’s location, handling, and condition. Bio-based Materials: Researchers are exploring bio-based alternatives to traditional corrugated materials, such as bio-based adhesives and coatings, as well as biodegradable or compostable fiberboards. These materials offer increased sustainability and reduced environmental impact. Intelligent Packaging Design: Designers are incorporating features such as perforations, tear strips, and resealable elements into box designs, enhancing user convenience and reusability. If you are interested in custom corrugated boxes, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging is an integral part of the overall customer experience, providing protection, information, and branding to the products we buy. However, when it comes to shipping goods, the protective aspect of packaging becomes increasingly crucial. This blog will delve into the role of protective packaging in reducing product damage during transport and storage. Understanding Protective Packaging Before we can fully understand the role protective packaging plays in reducing product damage, it’s crucial to know what it is. Protective packaging, as the name implies, is designed to safeguard products from damage during shipment and storage. This can include materials such as bubble wrap, foam inserts, air pillows, corner protectors, and many other types of specialized packaging. The primary goal of protective packaging is to ensure that a product arrives at its destination in the same condition as when it left the warehouse or factory. It achieves this by absorbing shocks, preventing scratches or scuffs, and protecting against environmental factors such as moisture or temperature changes. The Impact of Product Damage Product damage can have far-reaching effects beyond the immediate financial loss of the product itself. These can include: Negative customer experience: A damaged product is likely to lead to an unhappy customer, which can result in negative reviews and lower repeat business. Increased costs: Besides the obvious cost of the damaged product, there can be additional costs associated with returns, replacements, and potentially even compensation for the customer. Brand reputation: Regular occurrences of damaged products can harm a company’s reputation, leading to a loss of trust and potential customers. Environmental impact: Damaged products often end up in landfills, contributing to environmental pollution. Given these impacts, it’s clear why protective packaging is so important. The Role of Protective Packaging in Damage Reduction Protective packaging plays a key role in damage reduction in several ways: Cushioning and Shock Absorption This is perhaps the most obvious role. Materials such as bubble wrap, foam inserts, or inflatable air pillows provide a buffer around the product, absorbing any shocks or impacts that may occur during transit. This can prevent breakages, dents, and other physical damage. Filling Void Spaces Protective packaging such as packing peanuts or paper can fill the empty space in a box, preventing the product from moving around during transit. This can protect against scratches, scuffs, or other damage caused by the product colliding with the sides of the box. Protection from Environmental Factors Some types of protective packaging, such as barrier bags, can protect against environmental factors such as moisture, dust, or temperature changes. This can be crucial for products that are sensitive to these factors, such as electronics or certain types of food. The Future of Protective Packaging As technology evolves, so too does protective packaging. Innovations such as intelligent packaging systems are able to detect and alert when a package has been dropped or mishandled. Biodegradable and recyclable protective packaging options are also becoming more popular, helping to reduce the environmental impact of packaging. If you are interested in protecting your products effectively, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

As the packaging industry evolves, corrugated boxes continue to play a pivotal role in shipping, storage, and retail displays. In 2025, businesses will look for more innovative, eco-friendly solutions to meet the increasing demand for sustainability, efficiency, and enhanced user experiences. Below are the top trends expected to shape the future of corrugated boxes: Sustainable Materials and Recycling Lightweight Corrugated Designs Enhanced E-commerce Packaging Custom Branding and Personalization Smart and Connected Packaging Reusable Corrugated Solutions Minimalist Packaging Design Strengthened Protection Features Digital Printing on Corrugated Boxes Cost-Effective Packaging Solutions Sustainable Materials and Recycling Sustainability will be a core focus in 2025, and corrugated boxes will increasingly be made from recycled content and renewable resources. Businesses will prioritize using 100% recyclable and biodegradable materials, reducing the reliance on virgin fiber. In addition, closed-loop recycling systems will allow for more efficient material reuse. Lightweight Corrugated Designs Lightweight corrugated packaging will grow in popularity due to its ability to reduce transportation emissions and shipping costs. In 2025, more brands will adopt thinner yet stronger corrugated materials that maintain durability while cutting down on overall material usage, minimizing environmental impact. Enhanced E-commerce Packaging As e-commerce continues to expand, corrugated boxes specifically designed for online retail will be in high demand. These boxes will need to balance durability and protection with sustainability, using materials that are both sturdy and lightweight. Additionally, frustration-free packaging designs, which are easy to open and reduce excess waste, will become a standard. Custom Branding and Personalization Custom-printed corrugated boxes will remain a key trend in 2025 as brands seek to enhance the unboxing experience. Personalization and custom branding on corrugated boxes not only improve product presentation but also help businesses build stronger connections with consumers. Digital printing advancements will allow for more affordable and detailed customization options, even for small runs. Smart and Connected Packaging The integration of smart technology with corrugated boxes will increase, incorporating elements like QR codes, RFID tags, and NFC chips. These innovations provide real-time tracking information, ensure product authenticity, and allow consumers to interact with brands in new ways. Smart packaging is also expected to play a larger role in enhancing the supply chain with better inventory management and tracking. Reusable Corrugated Solutions In response to the push for more sustainable packaging, reusable corrugated boxes will see growing adoption. Brands are increasingly looking at designing corrugated packaging that can be used multiple times before disposal or recycling. This trend not only reduces waste but also offers cost savings for businesses focused on long-term sustainability. Minimalist Packaging Design Minimalism continues to dominate the packaging industry, with more brands opting for simple, clean designs that reduce the amount of material used. Minimalist packaging resonates with consumers who prefer environmentally conscious brands and products. In corrugated packaging, this trend translates into smaller, more efficient boxes that still offer high-level protection. Strengthened Protection Features With more sensitive products being shipped globally, the need for enhanced protection in corrugated boxes will rise. Advances in box construction and the integration of protective materials like inserts or reinforced corners will ensure better protection while minimizing material usage. Expect packaging that not only looks good but also performs better in harsh shipping conditions. Digital Printing on Corrugated Boxes Digital printing technology is expected to make huge strides by 2025, offering companies faster, more affordable customization on corrugated boxes. With fewer limitations on color and design complexity, businesses will be able to create vibrant, branded packaging in smaller runs, allowing for cost-efficient personalization without the need for large-scale production. Cost-Effective Packaging Solutions As businesses continue to navigate cost pressures, corrugated boxes will remain a go-to for affordable packaging. Innovations in materials, design, and production methods will help keep costs low while meeting the growing demands for sustainability and durability. Expect to see more flexible, cost-efficient options that still deliver on protection and presentation. In 2025, corrugated boxes will remain a crucial part of the packaging industry, balancing innovation with sustainability. Companies that adopt these trends will be well-positioned to meet evolving consumer and regulatory expectations while staying competitive in a dynamic marketplace. If your interested in corrugated boxes for 2025, whether they are custom or stock, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Corrugated Boxes Facebook Twitter LinkedIn Pinterest Relevant Posts

As e-commerce continues to grow rapidly, packaging plays a pivotal role in delivering products safely and creating memorable customer experiences. In 2025, brands will focus on innovative, eco-friendly solutions that enhance shipping efficiency while meeting sustainability goals. Here are the top trends expected to shape e-commerce packaging in 2025: Sustainable Materials Right-Sized Packaging Custom Branded Packaging Frustration-Free and Easy-Open Designs Reusable E-Commerce Packaging Smart and Connected Packaging Lightweight and Protective Packaging Minimalist Packaging Solutions Flexible Packaging for E-Commerce Cost-Effective Packaging Solutions Sustainable Materials Sustainability will continue to dominate the e-commerce packaging landscape in 2025, with businesses shifting towards eco-friendly materials like recyclable, biodegradable, and compostable options. Brands will prioritize packaging made from recycled materials to meet consumer demand for environmentally responsible choices. Right-Sized Packaging Right-sizing will become more crucial as brands work to reduce material waste and shipping costs. By using packaging that fits the product precisely, companies will minimize excess packaging, reduce void fill, and decrease the environmental impact associated with oversized packages. Custom Branded Packaging Personalization and branding will remain a key trend in e-commerce packaging in 2025. Businesses will use customized packaging to enhance the unboxing experience, build brand loyalty, and create memorable interactions with customers. Digital printing will allow brands to create custom designs without large print runs. Frustration-Free and Easy-Open Designs Consumers expect packaging that is easy to open and reduces waste. In 2025, frustration-free packaging will continue to gain momentum, ensuring that products are securely packaged but easy for customers to access. This trend will focus on eliminating excessive materials and improving user experience with simplified designs. Reusable E-Commerce Packaging Reusable packaging will be an important trend as companies explore sustainable alternatives to single-use options. Refillable or returnable packaging solutions will help reduce waste and offer customers a more eco-friendly option for receiving and returning products, particularly in industries like fashion and electronics. Smart and Connected Packaging By 2025, more e-commerce brands will incorporate smart technology into their packaging. RFID tags, QR codes, and NFC-enabled packaging will allow customers to interact with the product through their smartphones, providing information about the product’s journey, sustainability efforts, or exclusive promotions. Lightweight and Protective Packaging To balance shipping costs with product protection, businesses will adopt lightweight packaging materials that provide durability without adding unnecessary weight. Advanced materials and design innovations will help protect fragile or high-value items during transit while reducing transportation emissions and costs. Minimalist Packaging Solutions In response to both consumer demand and sustainability efforts, minimalist packaging designs will rise in popularity. Brands will opt for simple, clean packaging that uses fewer materials, reduces waste, and highlights eco-friendly messaging. This approach resonates with consumers who prioritize sustainability and value-conscious choices. Flexible Packaging for E-Commerce Flexible packaging—such as pouches and bags—will continue to gain traction in the e-commerce space due to its lightweight, space-saving properties. Flexible packaging reduces material waste and shipping costs while providing durability and protection for products of various shapes and sizes. Cost-Effective Packaging Solutions As businesses look to balance sustainability with budget constraints, cost-effective packaging solutions will be essential. Innovations in packaging design and material sourcing will allow companies to offer eco-friendly options without raising costs significantly, making sustainable packaging more accessible to businesses of all sizes. E-commerce packaging in 2025 will focus on balancing efficiency, sustainability, and customer experience. Companies that adopt these trends will be well-positioned to deliver high-quality, eco-conscious packaging solutions that meet both business needs and consumer expectations. If you’re interested in ecommerce packaging for 2025, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Ecommerce Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts