Home » Packaging Your Products in California

Packaging Your Products in California

Packaging is an essential aspect of product marketing, and it can play a significant role in attracting and retaining customers. Effective packaging can make a product stand out on the shelves and convey important information about the product’s features and benefits. However, packaging is not just about aesthetics and information; it also has legal and safety implications.

In California, packaging regulations are among the strictest in the country. The state has implemented laws and regulations aimed at reducing waste, encouraging recycling, and protecting the environment. Packaging regulations in California are intended to minimize waste, promote recyclability, and regulate the toxicity of packaging materials.

As a buyer in California, it is important to be aware of packaging regulations and requirements. By doing so, you can ensure that the products you sell meet legal and safety requirements and are packaged in a way that is environmentally friendly. This can help you appeal to customers who are increasingly environmentally conscious and prefer products that are sustainable and eco-friendly.

Additionally, working with a packaging supplier that is knowledgeable about California packaging regulations and offers sustainable packaging options can help ensure that your products are packaged in a way that meets legal requirements while still meeting your business needs. By choosing a supplier with experience, reputation, customization options, sustainability, and cost-effectiveness, you can be confident that your products are packaged appropriately and will appeal to your customers.

Overview of California Packaging Regulations

California, a state renowned for its stringent environmental laws, including packaging regulations, is committed to reducing waste, encouraging recycling, and safeguarding the environment. The Department of Toxics Control (DTSC) and Prop 65 – Warning are essential components of California’s efforts to achieve these goals.

The California Packaging Regulations (CPR) and the California Green Chemistry Initiative (CGCI) are the two primary packaging regulations in California. The CPR necessitates that businesses selling or distributing products in California adhere to specific packaging requirements to decrease waste and boost recycling rates. Businesses must reduce the amount of packaging used, employ lightweight materials, minimize the size of packaging, and eliminate extraneous packaging.

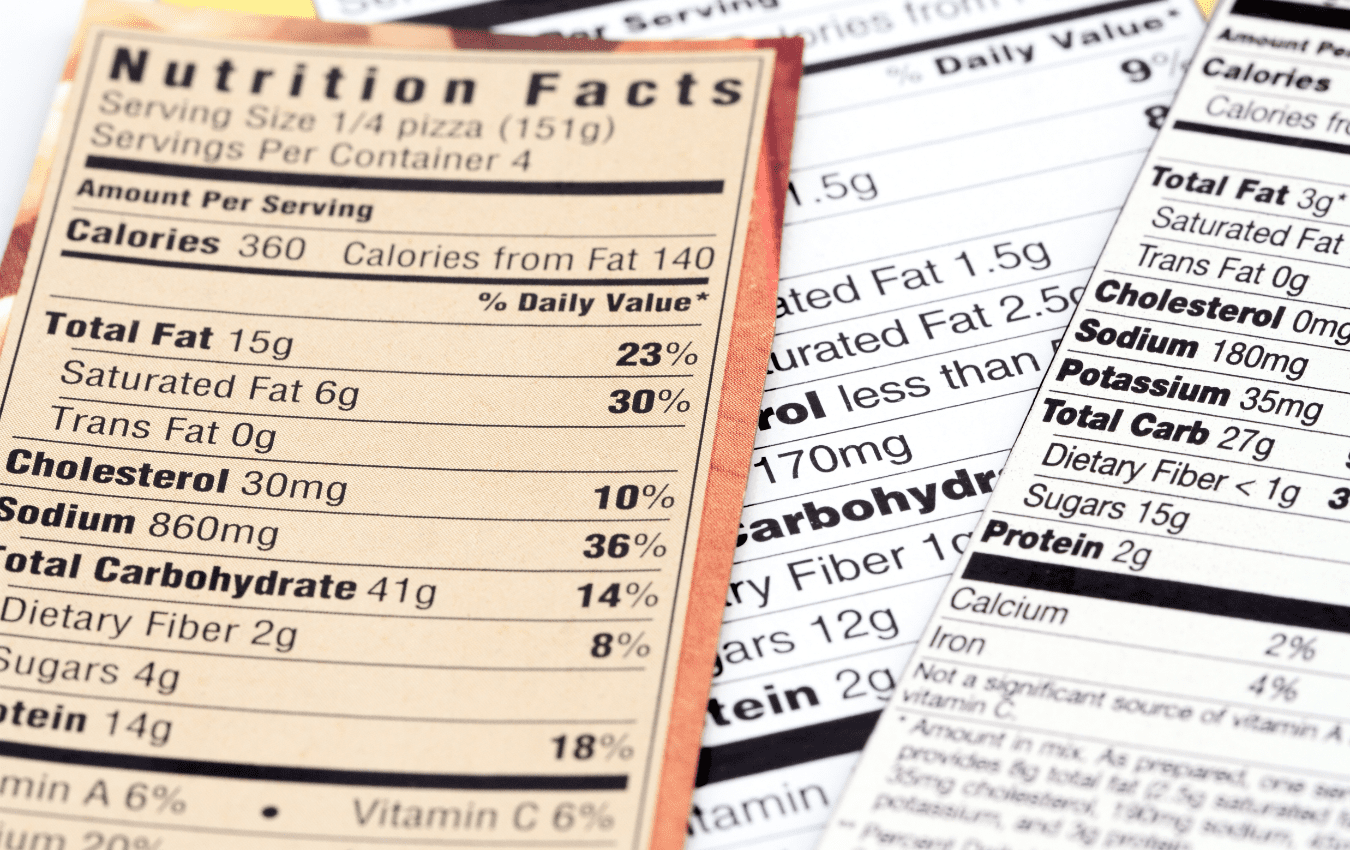

Moreover, the CPR requires businesses to employ materials that are easily recyclable in California, such as paper, cardboard, and specific plastic types. Additionally, the regulation governs the toxicity of packaging materials and necessitates that businesses employ materials that are safe for human health and the environment. Furthermore, businesses must label their packaging materials as recyclable or not to enable informed recycling decisions by consumers, encourage them to recycle more, and promote sustainability.

The CGCI, a set of regulations aimed at reducing the use of toxic chemicals in consumer products, including packaging, is another critical aspect of California’s packaging regulations. Businesses must evaluate the toxicity of chemicals used in their products, seek safer alternatives that are less harmful to human health and the environment, and disclose the presence of certain chemicals in their products, as well as provide information about safer alternatives.

Ultimately, the DTSC and Prop 65 – Warning are integral to California’s packaging regulations, which seek to promote sustainable packaging, reduce waste, and protect the environment. By following these regulations, businesses can decrease their environmental footprint and appeal to consumers seeking eco-friendly products.

Packaging Requirements

The California Packaging Regulations (CPR) require businesses to meet specific packaging requirements to minimize waste, promote recycling, and regulate the toxicity of packaging materials. Here are the key requirements:

- Source Reduction: The CPR requires businesses to minimize the amount of packaging used to package their products. This can be achieved by using lightweight materials, reducing the size of packaging, and eliminating unnecessary packaging. By reducing the amount of packaging, businesses can minimize waste and save money on materials and transportation costs.

- Recyclability: The CPR requires businesses to use materials that are easily recyclable in California. This includes materials such as paper, cardboard, and certain types of plastic. Businesses must also ensure that the materials they use are accepted by local recycling programs in California.

- Toxicity: The CPR regulates the toxicity of packaging materials and requires businesses to use materials that are safe for human health and the environment. This includes avoiding the use of toxic chemicals such as lead, cadmium, mercury, and hexavalent chromium in packaging materials. Businesses must also ensure that the materials they use do not pose a risk to human health or the environment when disposed of.

- Labeling: The CPR requires businesses to label their packaging materials to indicate whether they are recyclable or not. This labeling requirement helps consumers make informed decisions about recycling and encourages them to recycle more. Businesses must also ensure that their labels are accurate and clear, and that they comply with federal and state labeling requirements.

Meeting packaging requirements in California can be a challenge, but it is necessary to ensure that businesses are operating in compliance with the law and are minimizing their environmental impact. By following these requirements, businesses can create packaging that is both sustainable and cost-effective.

The Department of Toxics Control (DTSC)

The Department of Toxics Control (DTSC) is a California state agency tasked with regulating hazardous waste, toxic substances, and pollution prevention. Its main objective is to safeguard public health and the environment by ensuring that hazardous waste is handled and disposed of safely, and that toxic substances are used and managed responsibly.

DTSC enforces a variety of laws and regulations aimed at protecting the environment and public health. These include the Hazardous Waste Control Law, which regulates the generation, transportation, treatment, storage, and disposal of hazardous waste; the Hazardous Substances Account Act, which requires businesses that use or generate hazardous substances to contribute to a fund that is used to respond to releases of hazardous substances; and the Electronic Waste Recycling Act, which establishes a program for the recycling of certain electronic devices.

DTSC is also responsible for issuing permits for hazardous waste facilities, which must meet strict requirements to ensure that they operate safely and do not pose a threat to public health or the environment. Additionally, the agency oversees the cleanup of contaminated sites, working with responsible parties to ensure that these sites are cleaned up to meet state and federal standards.

Regarding packaging regulations, the DTSC plays a crucial role in ensuring that businesses comply with California’s strict requirements for packaging materials. The agency reviews and approves materials and products for compliance with California’s regulations, and it provides guidance to businesses on how to meet the state’s requirements. The DTSC also enforces penalties and fines for businesses that violate packaging regulations, as part of its efforts to promote sustainable packaging and reduce waste.

Prop 65

Proposition 65, or Prop 65 for short, is a California law that requires businesses to provide warnings to consumers about exposure to certain chemicals known to cause cancer, birth defects, or other reproductive harm. The law applies to a wide range of consumer products, including food, furniture, and electronics, as well as packaging materials.

Prop 65 requires businesses to provide clear and reasonable warnings to consumers if their products contain any of the chemicals on California’s list of substances known to cause cancer or reproductive harm. The warnings must be specific and include information about the chemical(s) in the product and the potential health risks associated with exposure.

Businesses can comply with Prop 65 by either providing warnings on their products or by removing the chemicals from their products altogether. The law also allows private citizens and organizations to file lawsuits against businesses that fail to provide the required warnings.

In the context of packaging regulations, Prop 65 plays an important role in protecting consumers from exposure to harmful chemicals in packaging materials. By requiring businesses to provide clear and accurate warnings, the law helps consumers make informed decisions about the products they purchase and use. Prop 65 also incentivizes businesses to find safer alternatives to chemicals known to cause harm, promoting the use of eco-friendly and non-toxic packaging materials.

Finding A Packaging Supplier

When it comes to finding a packaging supplier in California, businesses need to look for suppliers that are knowledgeable about California packaging regulations and can provide sustainable packaging options. Here are some key factors to consider when choosing a packaging supplier:

- Experience and Reputation: Choose a supplier with experience in the industry and a good reputation for delivering high-quality packaging. A supplier with a good reputation is more likely to provide reliable and consistent packaging solutions that meet your needs.

- Customization: Look for a supplier that can provide customized packaging solutions that meet your specific needs. The supplier should be able to create packaging that meets your unique requirements in terms of size, shape, materials, and design.

- Sustainability: Choose a supplier that offers sustainable packaging options that meet California packaging regulations. Sustainable packaging is becoming increasingly important to consumers who are looking for eco-friendly products. By using sustainable packaging, you can appeal to these customers while also reducing your environmental footprint.

- Cost: Consider the cost of the packaging and ensure it fits within your budget. The supplier should be able to provide cost-effective packaging solutions that meet your requirements without compromising on quality or sustainability.

- Responsiveness: Choose a supplier that is responsive and easy to work with. The supplier should be able to communicate effectively and provide timely responses to your questions or concerns. They should also be able to provide quick turnaround times for your orders.

When evaluating packaging suppliers, it is important to take your time and research your options thoroughly. By choosing a supplier that meets your needs in terms of experience, customization, sustainability, cost, and responsiveness, you can be confident that your products are packaged appropriately and will appeal to your customers.

Summary: Packaging in California

In conclusion, packaging is a crucial aspect of product marketing, and adhering to legal and safety requirements is essential. California has specific packaging regulations that businesses must follow, including the California Packaging Regulations and the California Green Chemistry Initiative. The Department of Toxics Control (DTSC) enforces these regulations and issues permits for hazardous waste facilities. Prop 65 also requires businesses to provide clear warnings to consumers about exposure to certain chemicals in packaging materials. By partnering with knowledgeable packaging suppliers and prioritizing sustainable packaging solutions, businesses can comply with legal requirements and appeal to eco-conscious customers. This contributes to a more sustainable future for California and beyond.

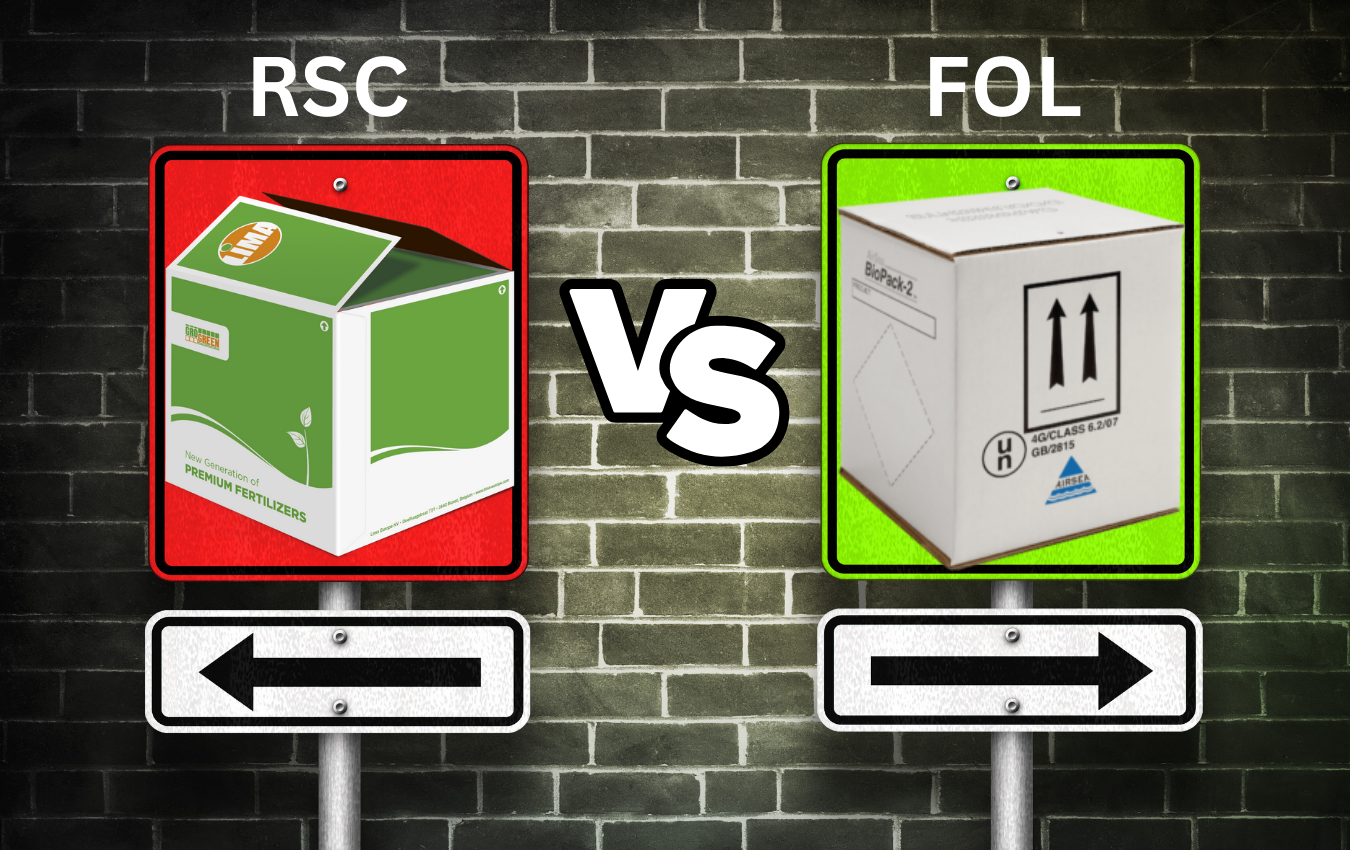

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Packaging Your Products in California

Packaging isn’t just a box or a bag—it’s a line item on your budget, a touchpoint with your customer, and a critical part of your

When it comes to packaging fragile products, the choice of packaging materials and techniques plays a critical role in ensuring your delicate items reach their

When it comes to packaging solutions, corrugated boxes offer versatility and protection. Among the common corrugated box styles are the Regular Slotted Container (RSC) box