Home » Packaging Prototypes: What You Need To Know

Packaging Prototypes: What You Need To Know

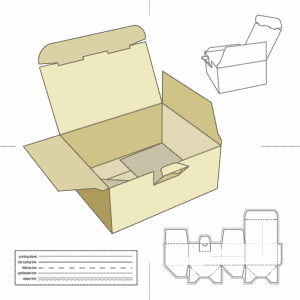

A packaging prototype is a sample or mockup of your packaging concept used to test function, design, and marketability before full production. Prototypes give buyers the opportunity to validate packaging performance, evaluate graphics, and make adjustments to avoid costly mistakes.

Why Prototypes Matter

Provide peace of mind before mass production

Serve as a final sign-off for manufacturing

Help buyers compare design variations and make informed decisions

Reduce risk of wasted materials, inventory loss, and branding errors

Concept Creation

First Article

Types of Packaging Prototypes

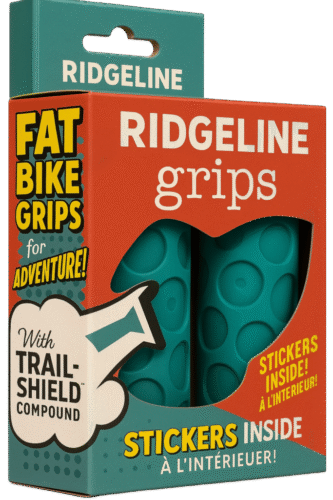

Physical Prototypes

Provide a tangible sample to inspect functionality, strength, and appearance. Typically produced with digital printing for cost efficiency.

Concept Creation (3D Mockups): Early-stage samples that show shape and function. May lack accurate color or material properties.

First Article: Pre-production sample created after an order is placed; ensures buyer approval before mass production.

Production Sample: Most accurate version pulled from the actual production line; costly and time-intensive, but best for high-value packaging.

Advantages: Hands-on inspection, true structural testing.

Limitations: Higher cost, longer lead times.

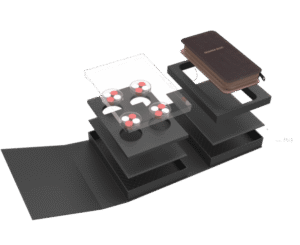

Virtual Prototypes

Digital methods using 2D or 3D modeling software.

3D Renderings: Photorealistic models created with CAD, often shown in simulated retail or supply chain environments.

2D Dielines: Flat layouts showing measurements, folds, and graphics. Useful for design alignment before physical production.

Advantages: Fast, low-cost, easily shared and modified.

Limitations: Not physically testable.

3D Rendering

2D Rendering

Key Considerations

Supplier Capabilities: Not all suppliers offer both physical and virtual methods.

Budget: Physical prototypes cost more; virtual is budget-friendly.

Packaging Type & Materials: Complex structures (like POP displays) cost more to prototype than simple mailers.

Lead Time: Virtual is faster; physical requires more resources and time.

When to Use Prototypes

Large Orders: To ensure packaging performs before scaling production.

Retail Presentations: Many retailers require physical samples for approval.

Supply Chain Testing: Validate structural integrity in shipping and handling.

Marketing Alignment: Digital prototypes allow easy collaboration across teams.

Ultimately, prototypes safeguard your investment by identifying issues early and ensuring your packaging meets both functional and branding goals.

Work With Brown Packaging

At Brown Packaging, we provide both physical and digital packaging prototypes to help businesses make confident decisions before production. Whether you need a structural sample, a 3D rendering, or a production-ready proof, our team ensures your packaging is tested, validated, and ready for market. Contact Brown Packaging today to get started.

References

Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

Institute of Packaging Professionals (IoPP). (2023). Prototyping in Packaging Development. Retrieved from https://www.iopp.org

Robertson, G. L. (2016). Food Packaging: Principles and Practice (3rd ed.). CRC Press.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Packaging Prototypes: What You Need To Know

Wine, the elixir of celebration and sophistication, demands packaging that not only safeguards its integrity but also reflects its prestige. Whether you’re a winery owner,

Flexible packaging stands out in the packaging industry for its adaptability and efficiency. Utilizing materials that can flex and mold, this type of packaging adjusts

For retail brands, Point of Purchase (POP) displays are crucial for maximizing product visibility and driving sales. Ensuring that these displays are retail-ready is key