Home » Packaging on a Budget: How Your Budget Can Affect Your Packaging Design

Packaging on a Budget: How Your Budget Can Affect Your Packaging Design

In today’s competitive marketplace, packaging has become one of the most crucial elements of any product. It not only protects the product but also plays a significant role in the marketing and branding of the product. However, creating a packaging design that effectively represents your brand while keeping costs under control can be challenging. Therefore, creating a budget for your packaging design is a critical aspect that should be considered by any business owner.

Quick Overview: 10 Ways Your Budget Is Impacting Your Packaging Design

In this blog post, we will explore how a budget can affect your packaging design.

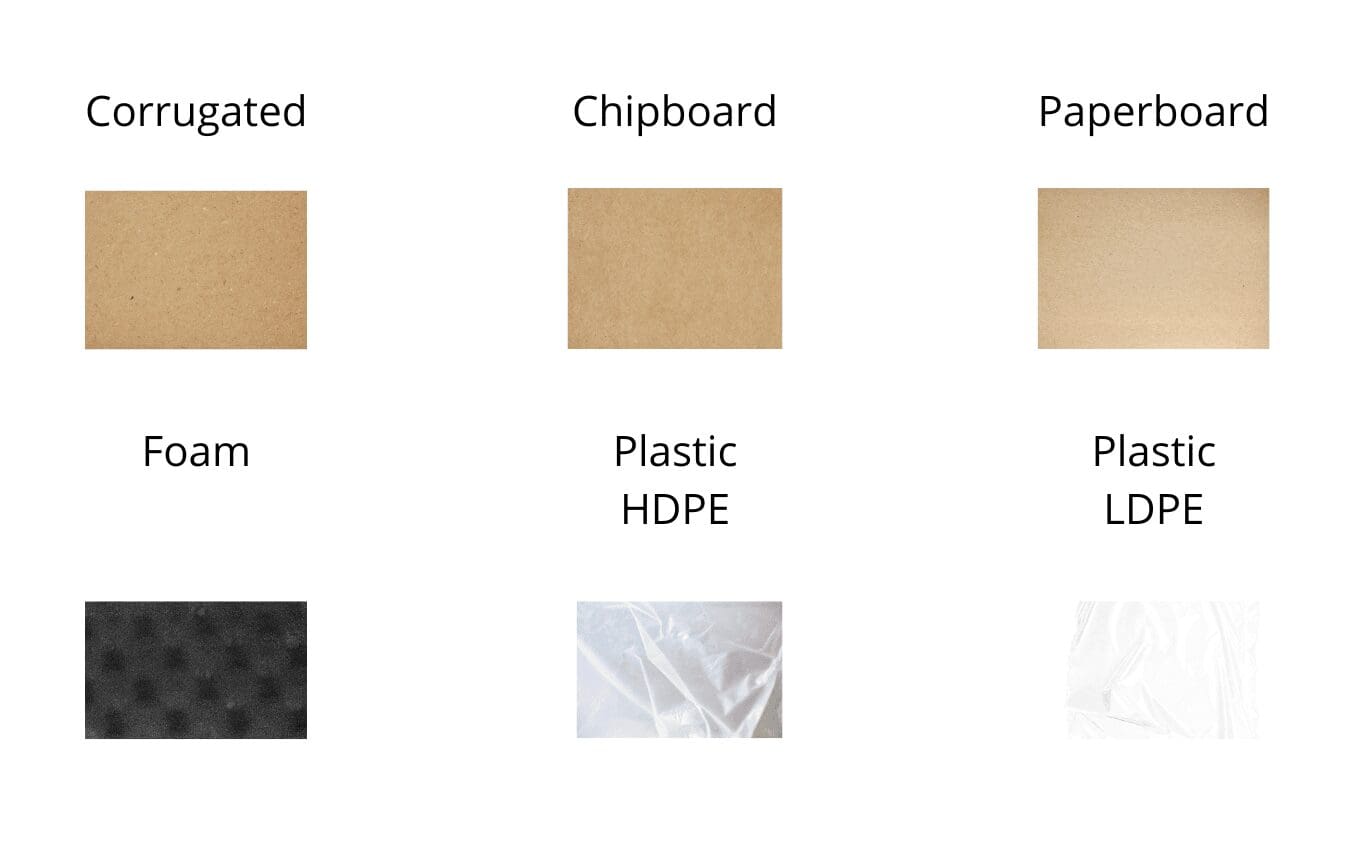

Material Selection

The materials used for packaging can vary significantly in cost. If you have a low budget, you may opt for less expensive materials such as paper or cardboard, while a higher budget may allow for more luxurious materials such as metal or glass. Additionally, different materials can have different benefits and drawbacks, such as eco-friendliness or durability, so it’s important to consider your budget when selecting materials.

Printing and Finishing

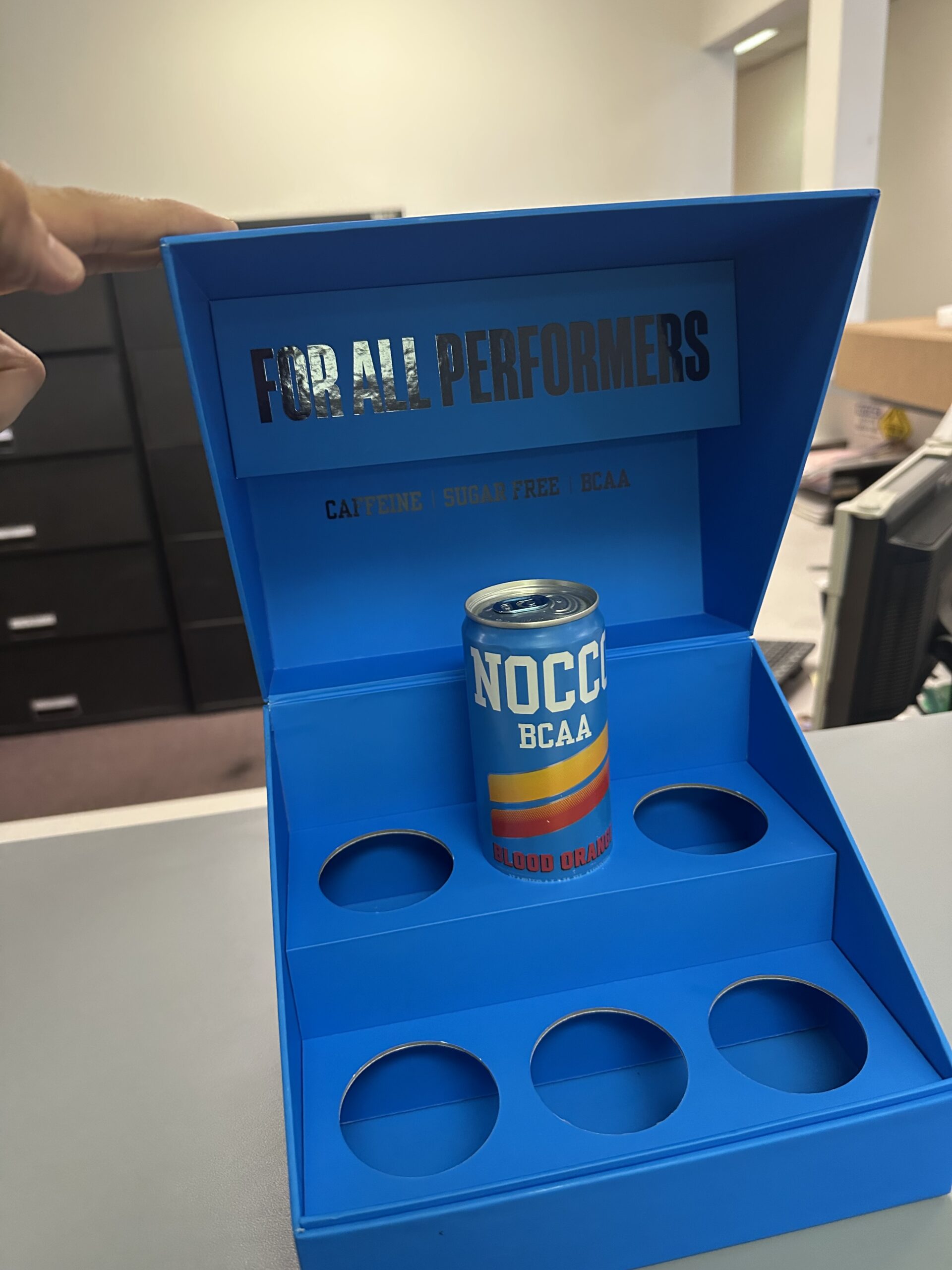

Packaging design can be enhanced with different printing and finishing techniques such as embossing, foil stamping, and spot UV printing. These techniques can add a significant visual impact to your packaging but can also be costly. Therefore, it’s crucial to consider the budget when deciding which printing and finishing techniques to use.

Customization

Customized packaging can help your brand stand out in a crowded market. However, customization can also increase costs significantly. The level of customization required will depend on your brand and the product being sold. For example, a luxury brand may require more custom packaging than a standard product. It’s essential to understand the level of customization required and its impact on the budget.

Quantity

The quantity of packaging produced can also impact the budget. Larger quantities can often lead to economies of scale, resulting in lower per-unit costs. Therefore, it’s crucial to determine the optimal quantity for your packaging design while considering your budget.

Logistics

The logistics of packaging can also affect the budget. The cost of shipping, warehousing, and storage should all be taken into account when creating a packaging budget. Additionally, any potential delays or issues in the supply chain can also impact the budget and should be considered when creating the budget.

Size and Shape

The size and shape of your packaging can have an impact on the budget. More intricate or unusual shapes may require custom tooling, which can be costly. Similarly, larger sizes may require more materials, increasing the overall cost. Therefore, it’s important to consider the size and shape of your packaging when creating a budget.

Design Complexity

The complexity of your packaging design can also impact the budget. More complex designs may require more time and resources to create, increasing the overall cost. Additionally, complex designs may require more materials or customization, which can further increase costs. Therefore, it’s important to consider the level of design complexity when creating a budget.

Branding Elements

Packaging is an important branding tool, and incorporating branding elements into your packaging can help build brand recognition and loyalty. However, incorporating branding elements into your packaging design can also increase costs. For example, using custom colors or adding a special color logo can increase printing costs. Therefore, it’s important to consider the branding elements you want to include in your packaging design when creating a budget.

Sustainable Materials

Sustainable packaging has become increasingly popular in recent years, as consumers become more environmentally conscious. However, sustainable materials can be more expensive than traditional materials, impacting the budget. Therefore, it’s important to consider the use of sustainable materials when creating a packaging budget.

Regulatory Compliance

Different products may have different regulatory requirements that impact the packaging design. For example, some products may require specific warning labels or safety features. Ensuring compliance with these regulations can impact the budget, as additional design elements or materials may be required. Therefore, it’s important to consider regulatory compliance when creating a budget for your packaging design.

Summary: Budgeting and Packaging Design

In conclusion, creating a packaging design that effectively represents your brand while staying within budget constraints is crucial. A budget can impact various elements of packaging design, such as material selection, printing techniques, customization, quantity, logistics, size and shape, design complexity, branding elements, sustainable materials, regulatory compliance, shipping and handling, target audience, industry standards, seasonal changes, and multilingual design.

As a result, businesses must carefully consider each of these factors when creating a packaging budget to ensure that they can create a packaging design that meets their needs and budget constraints. By doing so, businesses can not only create an effective packaging design but also save costs and improve their bottom line.

If you are interested in getting the best packaging solutions for your budget, then contact Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Packaging on a Budget: How Your Budget Can Affect Your Packaging Design

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

As the packaging industry evolves, corrugated boxes continue to play a pivotal role in shipping, storage, and retail displays. In 2025, businesses will look for

Saving on the purchase of corrugated boxes involves strategic planning and smart sourcing to ensure you get the best value without compromising on quality. By