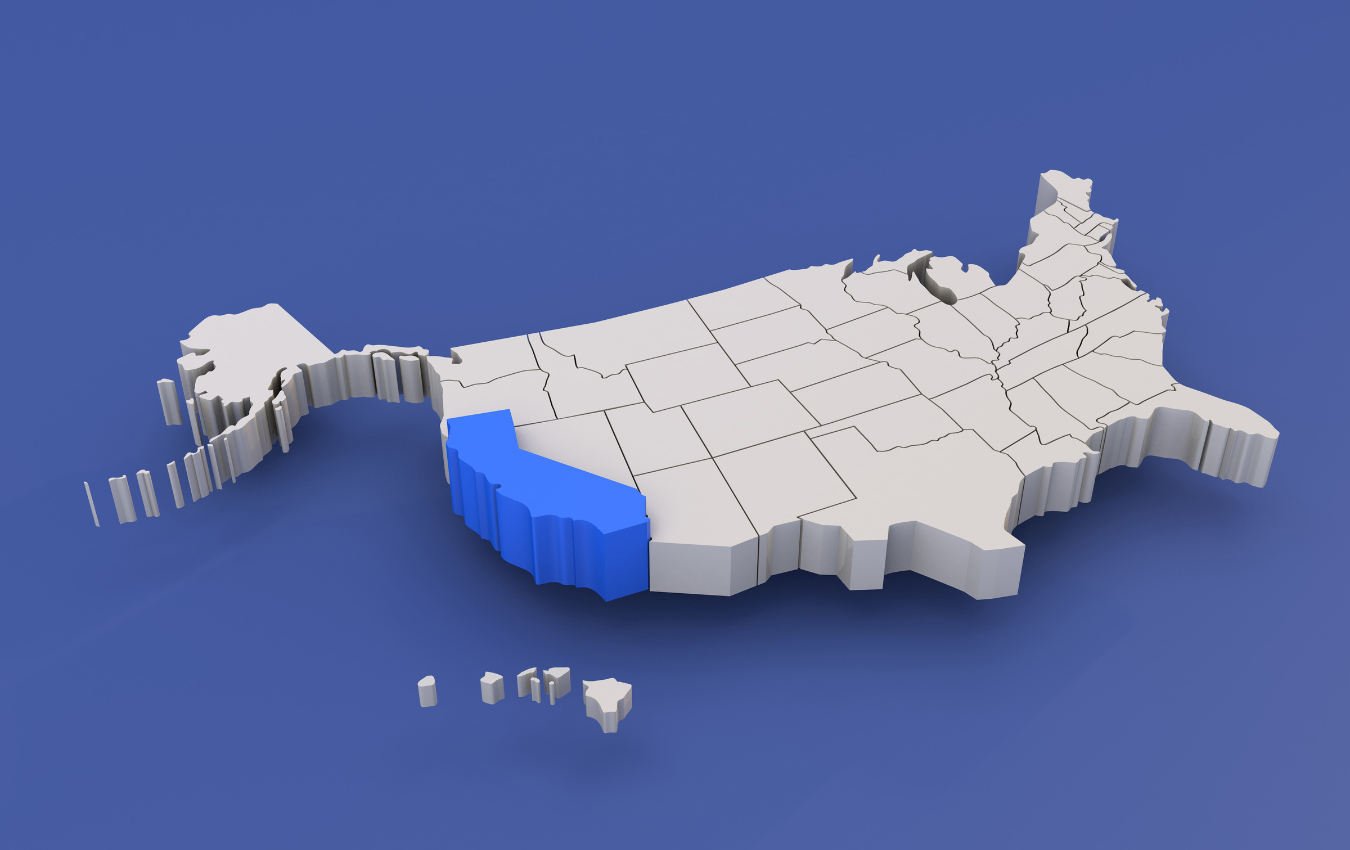

Home » Packaging in California vs. the Rest of the United States

Packaging in California vs. the Rest of the United States

Packaging plays a crucial role in product presentation, preservation, and sustainability. While packaging regulations across the United States generally adhere to federal guidelines, California stands out for its unique and stringent packaging laws. In this blog, we will explore the differences between packaging in California and the rest of the United States, examining regulations, sustainability initiatives, and their impact on businesses and consumers.

California’s Packaging Regulations: A Unique Landscape

California is known for its proactive approach to environmental protection, and its packaging regulations reflect this commitment. The primary difference between California and the rest of the U.S. lies in the state’s comprehensive and strict regulations aimed at reducing packaging waste and promoting recycling.

California’s Rigid Container Law

One of California’s standout packaging laws is the Rigid Plastic Packaging Container (RPPC) Act, which requires manufacturers to minimize packaging waste. This law mandates that RPPCs meet specific recycling criteria, such as using a minimum percentage of recycled content and being labeled with recycling symbols. Non-compliant products may face penalties.

Extended Producer Responsibility (EPR) Programs

California has been at the forefront of Extended Producer Responsibility (EPR) programs. Under EPR, manufacturers bear responsibility for the entire lifecycle of their packaging, from production to disposal. They must participate in recycling programs, fund collection systems, and meet specific recycling and recovery targets.

Plastic Waste Reduction Laws

California has implemented multiple laws aimed at reducing single-use plastics. Bans on single-use plastic bags, straws, and expanded polystyrene (Styrofoam) food containers are examples of such regulations. These measures have significant implications for packaging choices, particularly in the food and beverage industry.

Packaging Regulations in the Rest of the U.S.

While California leads in packaging regulations, the rest of the United States primarily follows federal guidelines established by agencies like the Environmental Protection Agency (EPA) and the Food and Drug Administration (FDA). These guidelines cover issues such as recycling labels, nutrition facts, and product safety.

Federal Recycling Labeling

Recycling labeling guidelines provided by the Federal Trade Commission (FTC) are used nationwide. These guidelines ensure consistency in recycling symbols and terminology. However, California may have additional requirements for products sold within the state.

Variability in State Regulations

Beyond federal guidelines, individual states may have their own packaging regulations, but they generally tend to be less stringent than California’s. States may focus on issues like bottle deposits or recycling programs but typically do not have laws as comprehensive as California’s RPPC Act or EPR programs.

Implications for Businesses and Consumers

Compliance Costs

Businesses operating in California face higher compliance costs due to the state’s strict packaging regulations. They must invest in sustainable packaging materials, meet recycling targets, and navigate complex reporting requirements. These costs can affect pricing and profitability.

Consumer Awareness

Consumers in California tend to be more aware of packaging sustainability due to the state’s active promotion of recycling and reduction of single-use plastics. This can influence their purchasing decisions and product preferences.

National Brands vs. Local Brands

National brands often create standardized packaging to comply with various state regulations, including California’s. Local or smaller brands may find it challenging to navigate the patchwork of state-specific requirements.

Sustainability Initiatives

California’s stringent regulations have spurred innovation in sustainable packaging materials and practices. These initiatives have the potential to influence packaging trends and best practices across the nation.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Packaging in California vs. the Rest of the United States

The packaging industry has undergone significant changes in recent years, with new technologies such as digital print revolutionizing the way packaging materials are produced. Digital

As tariff changes reshape global trade, packaging buyers moving production from China to the U.S. or nearshore regions face a new challenge: supplier qualification. Transitioning

Corrugated boxes are essential to shipping, retail, and e-commerce—but when you introduce custom printing, the stakes (and the opportunities) rise. Print isn’t just about looks—it’s