Home » Maximizing the Impact of Custom Packaging in Physical Retail Spaces

Maximizing the Impact of Custom Packaging in Physical Retail Spaces

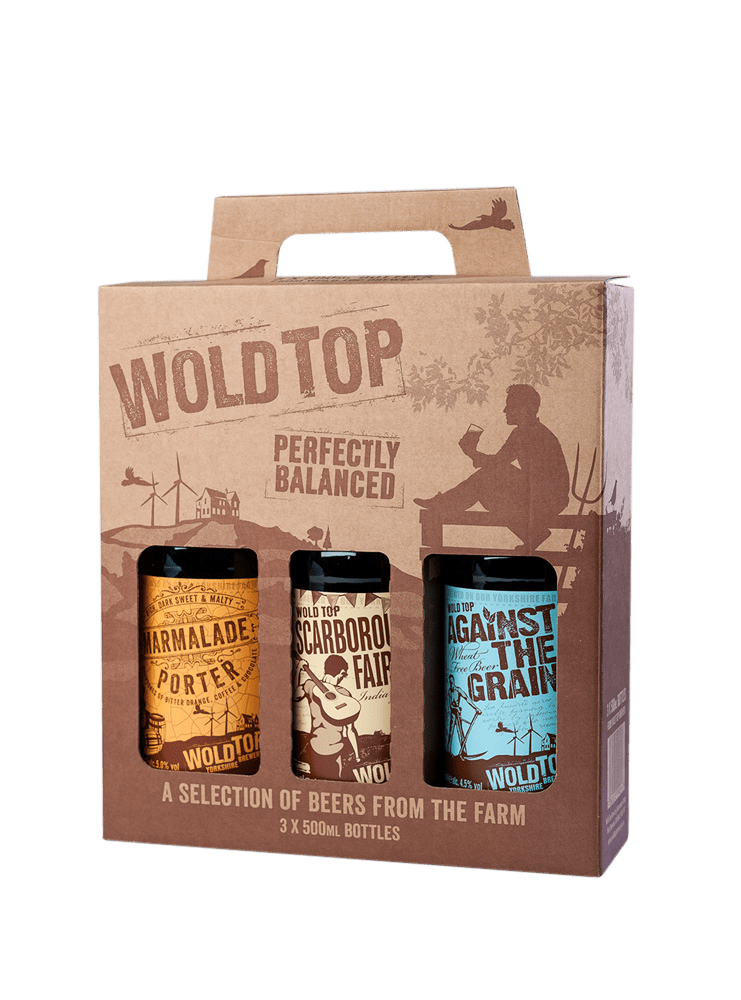

In the highly competitive world of physical retail, every tiny detail counts when it comes to attracting customers and encouraging them to purchase your products. One such crucial aspect that retailers can’t afford to overlook is custom packaging. Packaging is not just a protective measure, but also a powerful marketing tool that speaks volumes about your brand. This blog will focus on how to maximize the impact of custom packaging in physical retail spaces.

Understanding the Power of Packaging

Before we delve into strategies to enhance your custom packaging, it is vital to comprehend why packaging holds such importance in the retail environment.

Communicates Brand Values

Your packaging is the first physical interaction a potential buyer has with your product. It should clearly communicate your brand values, from quality and reliability to sustainability and creativity.

Creates a Lasting Impression

An attractive, well-thought-out package design can leave a lasting impression, stimulating repeat purchases and cultivating brand loyalty.

Influences Buying Decisions

Research indicates that approximately 70% of in-store purchases are impulsive. Effective packaging can stimulate these impulse buys by attracting and captivating shoppers’ attention.

With the significance of packaging well understood, let’s move on to how to maximize its impact.

Strategies for Maximizing the Impact of Custom Packaging

The following are some strategic approaches to make your custom packaging more impactful in a physical retail space:

Reflect Your Brand Identity

Your packaging should be a mirror image of your brand identity. It must reflect the ethos and aesthetics of your brand, using the right combination of colors, shapes, sizes, and materials.

Stand Out on the Shelves

In a physical store, your product is usually surrounded by competitors. Your packaging must stand out to attract customers.

Innovate with Shapes and Structures:

Try using innovative shapes and structures that differ from the norm. These can pique curiosity and draw attention.

Use Bold Colors and Patterns:

Bright, bold colors and patterns can make your packaging pop on the shelves. However, it’s essential to maintain consistency with your brand colors.

Leverage Sensory Appeal

Texture and material can enhance the tactile experience of your packaging, making it more memorable.

Soft-touch Coatings and Embossing:

These can give a more luxurious feel, while corrugated or craft paper can communicate eco-friendliness.

Opt for Sustainable Packaging

Sustainability is no longer an optional selling point; it’s a requirement. Many consumers are willing to pay more for products with eco-friendly packaging.

Materials Matter:

Opt for recycled or biodegradable materials. Not only are they better for the environment, but they also show your commitment to sustainability.

Make it Functional and Convenient

While aesthetics are important, functionality and convenience shouldn’t be compromised. A well-designed, functional package can enhance the user experience, increasing the chances of repurchase.

Easy to Open:

No one enjoys struggling with overly complex packaging. Make sure your packaging is easy to open.

Reusability:

Consider if your packaging can be reused in some way. This not only adds value for the customer but also contributes to sustainability.

Summary: Custom Packaging in Retail Space

Custom packaging offers a significant opportunity to make a lasting impression and motivate purchase decisions in physical retail spaces. By understanding the power of packaging and applying the above strategies, you can create impactful, appealing, and memorable packaging that resonates with your customers and stands out on the shelves.

If you’re interested in custom packaging, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Maximizing the Impact of Custom Packaging in Physical Retail Spaces

In 2022, businesses are experiencing a challenging time with increased cost of packaging materials such as corrugated, plastic, chipboard, thermoform, and other products. In addition,

Packaging is a critical component of our daily lives, serving a dual purpose of protecting products and conveying vital information to consumers. In the wake

In today’s highly competitive marketplace, the packaging of a product plays a crucial role in determining a brand’s success. It is the first point of