Home » Maximizing Product Protection with Corrugated Box Inserts

Maximizing Product Protection with Corrugated Box Inserts

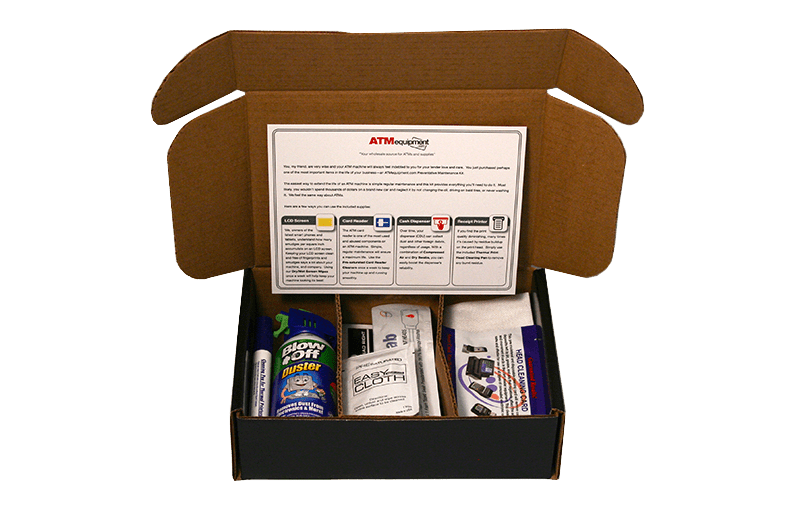

Corrugated box inserts are a key player in the world of packaging solutions. Not only do they secure and protect the products during transit, but they also add an extra level of professionalism and aesthetic appeal when unboxing. This blog post will delve into the various aspects of corrugated box inserts and how they help in maximizing product protection.

Understanding Corrugated Box Inserts

What are Corrugated Box Inserts?

Corrugated box inserts are specifically designed components that fit inside the packaging box to provide a structured and safe space for the product. They can be customized to fit any product’s shape and size, thereby reducing movement and minimizing the risk of damages during transportation or handling.

Materials Used in Corrugated Box Inserts

Corrugated is a popular choice for inserts due to its strength, durability, and cost-effectiveness. It offers excellent shock absorption properties, reducing the impact on the products within. Moreover, corrugated inserts are sustainable, making them an environmentally friendly packaging solution.

Benefits of Using Corrugated Box Inserts

Improved Product Protection

Corrugated box inserts offer excellent product protection. The inserts provide a snug fit for the products, limiting their movement within the box and minimizing potential damage caused by shocks and impacts during transportation.

Enhanced Product Presentation

Aside from protection, the inserts also enhance the unboxing experience. A well-designed insert can hold the product in place, present it effectively, and even highlight specific components or features.

Customizable and Versatile

The versatility of corrugated box inserts allows them to be tailored to any product’s shape and size, creating a custom solution that ensures optimal product protection.

Effective Practices for Maximizing Protection with Corrugated Box Inserts

Designing for the Product

The design of the insert should cater to the product’s unique dimensions and fragility. A custom-fitted insert provides more security than a generic one, as it ensures the product fits perfectly, minimizing movement within the box.

Multi-Layering for Extra Protection

For more fragile items, using multi-layered corrugated box inserts can provide additional protection. The layers create an extra barrier, increasing the resistance to impact and shock.

Incorporating Protective Padding

Depending on the product, incorporating protective padding within the insert can help absorb impact. This is particularly beneficial for delicate items such as electronics, glassware, or ceramics.

Summary: Corrugated Box Inserts

In a world where online shopping is becoming increasingly prevalent, ensuring that products arrive safely at their destination is of paramount importance. This is where corrugated box inserts shine, by offering an effective and sustainable solution to maximize product protection. By investing in well-designed corrugated box inserts, companies can reduce product damage, increase customer satisfaction, and improve their overall brand image.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Maximizing Product Protection with Corrugated Box Inserts

Selecting the right board option for your packaging needs is critical to ensuring product protection, cost efficiency, and customer satisfaction. However, with various materials and

Corrugated packaging has been a popular choice for packaging and shipping goods for over a century, and for good reason. The unique structure of corrugated

Corrugated boxes are more than mere containers; they’re the culmination of engineering, design, and environmental consideration. This advanced guide delves into the nuances of corrugated