Home » Luxury Packaging Explained: Applications, Benefits & More

Luxury Packaging Explained: Applications, Benefits & More

What Is Luxury Packaging?

Luxury packaging is designed to communicate exclusivity, premium quality, and sophistication. High-end brands rely on these packaging solutions to create a lasting impression, reinforcing their brand identity and elevating the perceived value of their products. Unlike standard packaging, luxury packaging is crafted with premium materials, intricate designs, and high-end finishes, making it an essential component for brands that cater to discerning consumers.

From rigid boxes (set-up boxes) to high-quality corrugated packaging, luxury packaging is built for durability and aesthetic appeal. These materials not only offer superior product protection but also enhance the unboxing experience, a critical factor in high-end consumer markets. The attention to detail extends to custom inserts, specialty closures, and premium printing techniques, ensuring that every aspect of the packaging reflects the brand’s prestige.

Why is Luxury Packaging Important?

Luxury packaging is important because there is always a demand for it, research has shown consumers are willing to spend more on products if the packaging looks appealing and luxurious. These consumers are looking to purchase products that reflect their personality, lifestyle and desired lifestyle. Packaging companies that supply luxury packaging products are fulfilling the needs of companies that position themselves as high end and consumers that like expensive and exclusive items..

Competition is always a key driver on why luxury packaging is essential. Nowadays, consumers have access to millions of products at the tip of their fingers due to technology and the internet. As a result, many brands really have to make their products stand out from the competition, which means spending money in conveying their message, packaging design that appeals and acquires customers, reflects brand image and quality.

Why Luxury Packaging Matters

Luxury packaging plays a pivotal role in influencing purchasing decisions. Studies show that consumers are more likely to spend on products with high-end, visually appealing packaging, as it reflects quality, status, and exclusivity. For premium brands, the packaging is more than just protection—it’s a statement of value that strengthens customer loyalty and differentiates them in a crowded marketplace.

In an era where online shopping dominates, luxury packaging becomes even more crucial. Consumers are flooded with choices, and brands must stand out through superior presentation. The unboxing experience, especially in e-commerce and retail, serves as an opportunity to leave a lasting impression, encourage social sharing, and enhance customer satisfaction.

Luxury Packaging Materials & Finishes

Luxury packaging is typically crafted from rigid boxes, high-quality corrugated materials, or specialty paperboard, ensuring a sturdy structure. However, the finishing touches define its premium look and feel. Some of the most common luxury packaging enhancements include:

- High-Quality Printing – Digital or lithographic printing for vibrant, detailed graphics.

- Embossing & Debossing – Raised or indented designs for tactile elegance.

- Foil Stamping – Metallic accents that enhance luxury appeal.

- Soft-Touch Matte & UV Coatings – Velvety finishes that add sophistication.

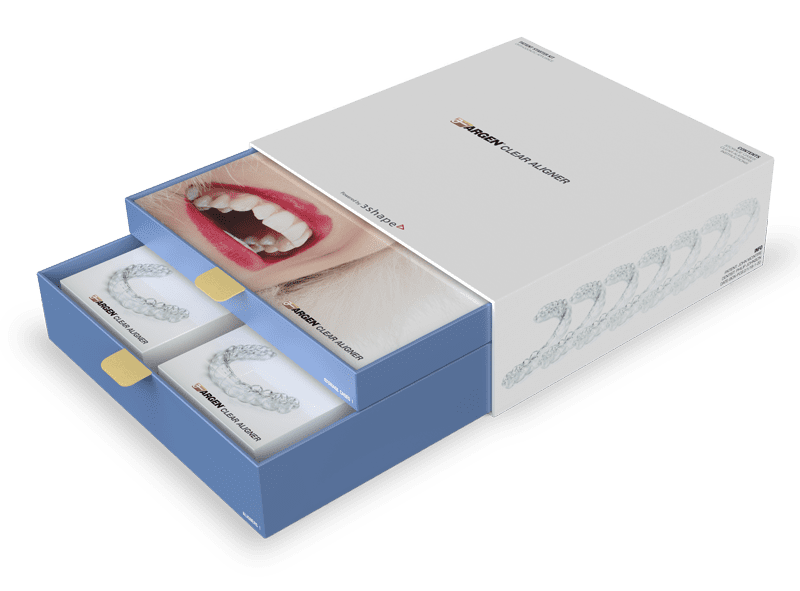

- Custom Inserts – High-end foam or paperboard inserts for protection and display.

- Premium Closures – Magnetic clasps, ribbon ties, or sliding drawers for a refined feel.

Common Applications of Luxury Packaging

Luxury packaging is widely used across multiple industries, where branding and presentation are paramount. Some of the most common sectors benefiting from high-end packaging include:

- Beverages: Fine wines, spirits, and specialty drinks require elegant display boxes for retail and gifting.

- Cosmetics & Beauty: Perfumes, skincare products, and premium makeup brands utilize luxury packaging to enhance their perceived value.

- Electronics: High-end tech products like smartphones, laptops, and watches demand premium packaging to reinforce their quality.

- Medical & Pharmaceuticals: Expensive medical devices and diagnostic kits benefit from secure and visually appealing packaging.

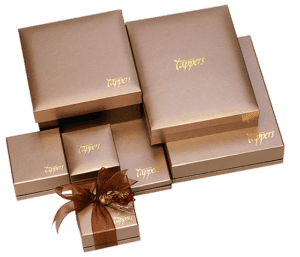

- Retail & Fashion: Designer apparel, luxury accessories, and jewelry often come in rigid boxes or custom-branded packaging for an upscale presentation.

Benefits of Luxury Packaging

Luxury packaging provides a range of advantages that go beyond aesthetics. Some key benefits include:

✔ Enhanced Customer Experience: A well-designed package creates a memorable unboxing experience.

✔ Higher Perceived Value: Luxury packaging allows brands to command premium pricing for their products.

✔ Brand Differentiation: Unique, well-crafted packaging sets brands apart from competitors.

✔ Product Protection: Rigid and corrugated materials provide superior protection during shipping and handling.

✔ Increased Sales & Customer Retention: Consumers are more likely to re-purchase and recommend products with high-quality packaging.

Where to Source Luxury Packaging

Not all packaging providers specialize in luxury packaging. Due to the complexity of structural design, material selection, and printing techniques, it’s essential to partner with an experienced supplier that can provide a seamless solution from concept to production.

At Brown Packaging, we specialize in custom luxury packaging solutions, offering high-end materials, premium finishes, and tailored designs to fit your brand’s needs. Whether you require rigid boxes, custom inserts, or specialty coatings, our team ensures that your packaging reflects the exclusivity and quality your customers expect.

Contact Brown Packaging today to discuss your luxury packaging project and explore the best solutions for your brand.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Luxury Packaging Explained: Applications, Benefits & More

Point-of-purchase (POP) displays are designed to capture shopper attention and influence buying decisions. Beyond structure and branding, the quality of print determines how well a

Holiday e-commerce volumes push packaging to its limits. Trailers are overfilled, handling is rushed, and parcels endure more drops and vibration than usual. Without proper

Gift-giving is a timeless tradition, and the packaging plays a crucial role in making the gesture even more special. When it comes to choosing the