Home » It’s Not Cardboard, It’s Corrugated

It’s Not Cardboard, It’s Corrugated

The terms cardboard and corrugated are often used interchangeably, but in packaging, they mean very different things. Cardboard is a catch-all term used by consumers, while corrugated and chipboard each have specific material definitions and applications. Knowing the difference helps buyers choose the right packaging solution and avoid costly mistakes.

Corrugated: Material and Products

Corrugated material is built from at least three layers: an inside liner, an outside liner, and a fluted medium in between. Additional layers can be added to improve compression and stacking strength. This structure makes corrugated ideal for protective and high-strength packaging.

Products Made with Corrugated

Sheets and inserts

Corrugated is available in natural kraft brown or bleached white. The brown color often leads consumers to mistakenly call it “cardboard.”

Chipboard: Material and Products

Chipboard (sometimes called paperboard) is manufactured by pressing small wood particles with resin under heat and pressure to form a smooth, rigid sheet. While it is lightweight and inexpensive, it does not provide the same compression or stacking strength as corrugated.

Products Made with Chipboard

Folding cartons for small, lightweight goods

Dividers and partitions

Inserts and sleeves

Chipboard is commonly used in retail-ready cartons for cereal, cosmetics, and lightweight consumer goods. Like corrugated, it typically appears in white or brown, reinforcing the consumer misuse of the word “cardboard.”

Why the Difference Matters

Using the wrong material for packaging can affect cost, product safety, and supply chain efficiency. For example:

Corrugated is essential when structural strength and stacking are required (shipping boxes, displays, bulk distribution).

Chipboard works when lightweight retail packaging is sufficient (folding cartons, retail sleeves).

Referring to corrugated as “cardboard” may cause confusion when sourcing from suppliers who distinguish between the two.

Selecting the right supplier also matters — not all packaging providers manufacture or stock both corrugated and chipboard. Working with one that does ensures consistent quality, efficiency, and fewer inventory issues.

Corrugated Box

Folding Carton (Chipboard)

Work With Brown Packaging

At Brown Packaging, we help businesses choose between corrugated, chipboard, and other packaging materials based on product needs, cost goals, and supply chain requirements. Whether you need protective shipping boxes or retail-ready cartons, our team can guide you through every step. Contact Brown Packaging today to get started.

References

Fibre Box Association. (2023). Corrugated Material Basics. Retrieved from https://www.fibrebox.org

Paperboard Packaging Council. (2023). Chipboard and Folding Carton Applications. Retrieved from https://paperbox.org

Soroka, W. (2016). Fundamentals of Packaging Technology (5th ed.). Institute of Packaging Professionals.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » It’s Not Cardboard, It’s Corrugated

Packaging inserts play a vital role in optimizing the protection and presentation of products during shipping and handling. In this blog, we will explore the

RSC boxes dominate shipping because they combine strength with efficiency. But beyond protection, their dimensions and stacking performance directly influence freight cost, pallet utilization, and

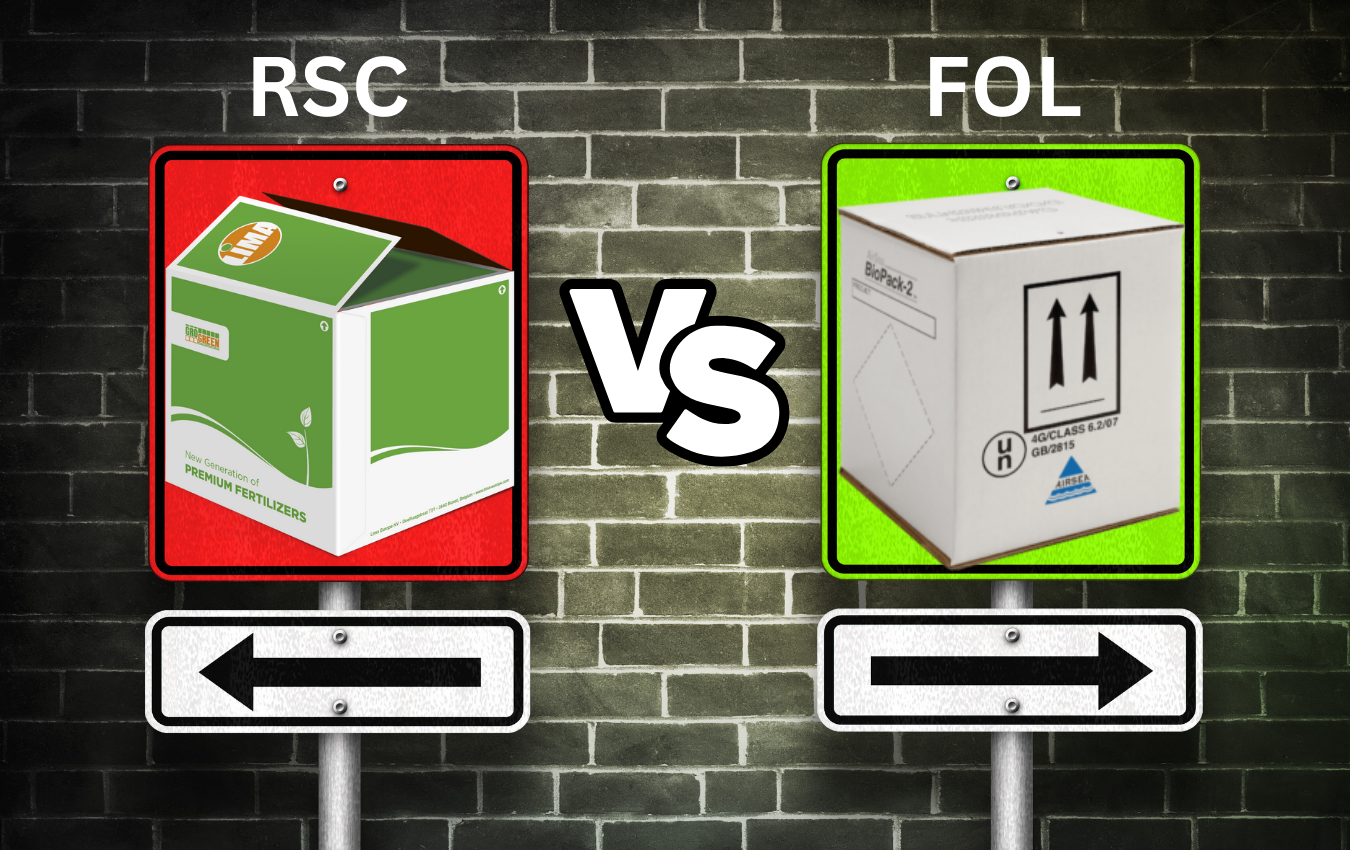

When it comes to packaging solutions, corrugated boxes offer versatility and protection. Among the common corrugated box styles are the Regular Slotted Container (RSC) box