Home » The Importance of Cold Chain Packaging in Maintaining Product Quality

The Importance of Cold Chain Packaging in Maintaining Product Quality

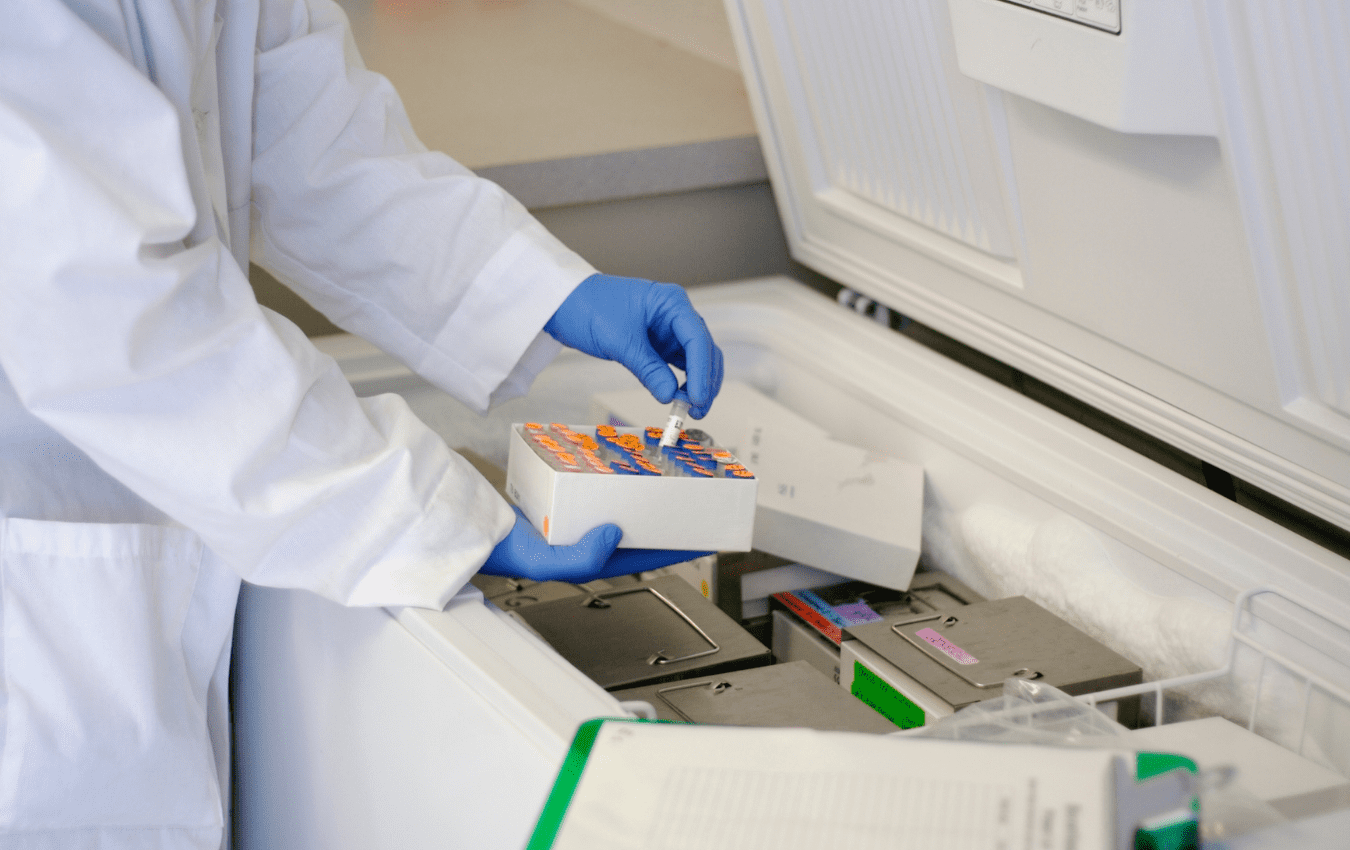

The cold chain is a temperature-controlled supply chain that plays a critical role in ensuring that certain products, such as pharmaceuticals, vaccines, and food, maintain their quality and efficacy. In this supply chain, the temperature is controlled, monitored, and maintained from the point of manufacture to the point of consumption. Cold chain packaging is an integral part of this process, as it provides a protective environment for temperature-sensitive products during transport and storage.

In this blog, we will discuss the importance of cold chain packaging in maintaining product quality, including the various types of cold chain packaging, their benefits, and the challenges associated with cold chain packaging.

What is Cold Chain Packaging?

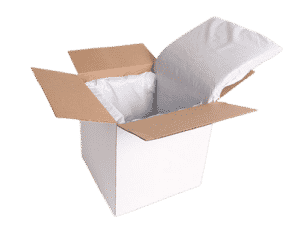

Cold chain packaging is the packaging used to protect temperature-sensitive products during transportation and storage. It is designed to maintain a specific temperature range to prevent product degradation and spoilage. Cold chain packaging is used in various industries, including pharmaceuticals, biotech, food, and beverage.

Types of Cold Chain Packaging

There are several types of cold chain packaging available, including:

- Insulated Shippers – Insulated shippers are designed to maintain a specific temperature range for a specific duration. These shippers can be made from various materials, including expanded polystyrene (EPS) containers, insulated mailers, foil bubble liners, polyurethane cooler boxes and paper-based liners. They are commonly used for transporting vaccines, blood samples, and temperature-sensitive medications.

- Refrigerants – Refrigerants are used in cold chain packaging to maintain a specific temperature range. These can be in the form of gel packs, dry ice, or liquid nitrogen. They are placed in insulated shippers to maintain the desired temperature range.

- Phase Change Materials (PCMs) – PCMs are substances that can store and release thermal energy during a phase change. These materials are commonly used in cold chain packaging to maintain a specific temperature range for extended periods.

Benefits of Cold Chain Packaging

- Maintains Product Quality – Product quality is maintained by keeping products within a specific temperature range during transportation and storage. This ensures that products remain effective and safe for consumption.

- Reduces Waste – Waste is reduced by preventing spoilage and degradation of products during transportation and storage. This helps reduce the need for product recalls, which can be costly for manufacturers.

- Increases Shelf Life – Shelf life is increased for temperature-sensitive products by maintaining a specific temperature range. This helps ensure that products can be stored for longer periods without degrading or spoiling.

Challenges Associated with Cold Chain Packaging

- Temperature Control – Temperature control is one of the most significant challenges associated with cold chain packaging. Maintaining a specific temperature range throughout the transportation and storage process can be challenging, especially in extreme weather conditions.

- Cost – It can be expensive, which can be a significant barrier for small manufacturers. The cost of materials, such as insulated shippers and refrigerants, can add up quickly.

- Regulatory Compliance – Cold chain packaging must comply with various regulations, including those set by the FDA and other regulatory bodies. Ensuring compliance with these regulations can be challenging and costly for manufacturers.

Summary: Cold Chain Packaging Explained

Cold chain packaging plays a critical role in maintaining product quality and safety during transportation and storage. It helps reduce waste, increase shelf life, and ensure that products remain effective and safe for consumption. However, there are challenges associated with cold chain packaging, including temperature control, cost, and regulatory compliance. Despite these challenges, the benefits of cold chain packaging outweigh the costs and challenges, making it an essential part of the cold chain supply chain.

If you are interested in cold chain packaging solutions, then contact Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » The Importance of Cold Chain Packaging in Maintaining Product Quality

In e-commerce, packaging plays a crucial role in protecting products, creating a memorable unboxing experience, and building brand loyalty. Within packaging, there are different layers,

Packaging is an essential aspect of any product’s marketing strategy. It is often the first point of contact with the consumer and can greatly influence

Packaging is an essential aspect of the modern supply chain, serving as a protective shield for products, preserving their quality, and enhancing their marketability. Among