Home » Impact of Recycled Fiber Content on Corrugated Box Durability

Impact of Recycled Fiber Content on Corrugated Box Durability

Incorporating recycled fiber into corrugated board is essential for sustainability goals, but it directly affects the mechanical properties of packaging. Understanding how fiber composition influences durability allows packaging engineers to strike the right balance between performance and environmental impact.

Fiber Strength and Recycling Cycles

- Virgin Fiber: Longer, more intact cellulose fibers that offer superior tensile and compression strength.

- Recycled Fiber: Shorter fibers due to repeated processing; reduced bonding potential and stiffness.

- Fiber Degradation: Each recycling cycle shortens fibers, leading to diminished ECT and burst resistance.

Mechanical Trade-Offs

- High Recycled Content: Lower material cost and improved sustainability metrics, but reduced edge crush strength and puncture resistance.

- Mixed Fiber Blends: Commonly used to maintain performance while increasing recycled content.

Moisture Sensitivity

- Recycled fibers tend to absorb and retain more moisture, accelerating loss of stacking strength in humid environments.

- Sizing agents and moisture-resistant coatings can partially offset this effect.

Testing Protocols

- ASTM D685: Standard practice for conditioning paper and paper products before testing.

- TAPPI T410: Grammage testing to verify consistency in basis weight.

- Long-Term Compression Testing: To monitor creep and compression loss over storage periods.

Application Guidelines

- Use higher recycled content in light-duty e-commerce boxes where high stacking strength isn’t required.

- Retain virgin outer liners for high-performance applications like industrial goods or long-distance freight.

References

ASTM International. (2014). ASTM D685-14: Standard practice for conditioning paper and paper products for testing. ASTM International. https://www.astm.org/d0685-14.html

Technical Association of the Pulp and Paper Industry. (2013). TAPPI T410 om-13: Grammage of paper and paperboard. TAPPI. https://www.tappi.org/content/store/shared/T410.html

Fibre Box Association. (2023). Corrugated recycling and performance considerations. Fibre Box Association. https://www.fibrebox.org

Beyond standard drop and compression tests, advanced performance testing provides deeper insight into how folding cartons behave under real-world stresses. These methods help packaging engineers predict failures, validate material changes,

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to ensure folding cartons perform as

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected for a specific function. The

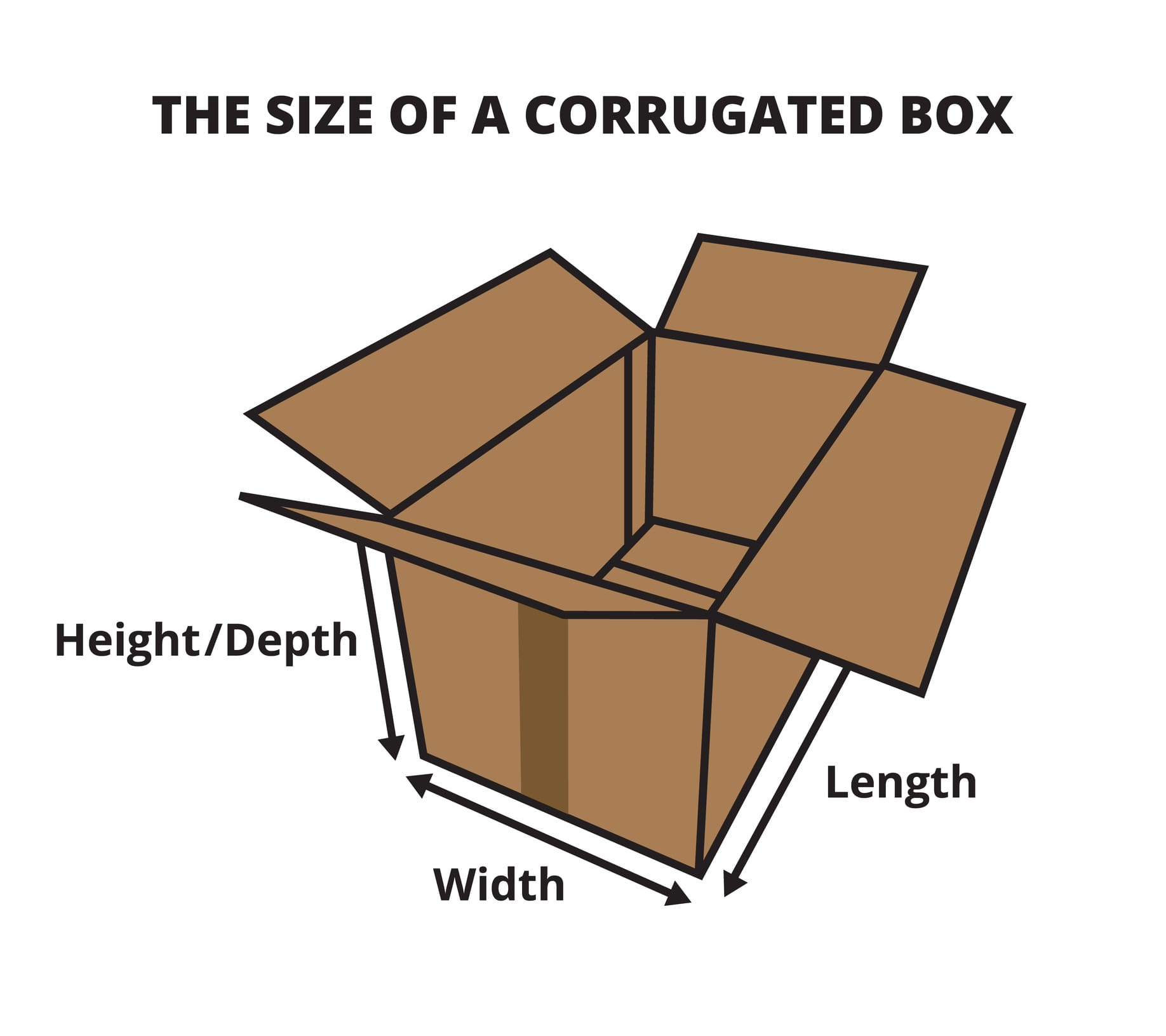

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies to reduce freight costs, improve

Home » Impact of Recycled Fiber Content on Corrugated Box Durability