Home » How To Protect Your Packages In a Supply Chain Environment

How To Protect Your Packages In a Supply Chain Environment

In a supply chain, your packaging is subjected to various stresses, including being pushed, pulled, dropped, and compressed against other packages. Proper packaging techniques are crucial for minimizing product loss, ensuring successful product launches, and avoiding shortages due to damages incurred during shipment.

Overview: Effective Strategies to Enhance Packaging Protection

Packaging not only needs to be attractive but also robust enough to protect the contents from the rigorous conditions of the supply chain. Here are comprehensive strategies to ensure your packaging holds up under stress and delivers your products safely to their destinations.

Consider Packaging Inserts, Partitions, and Dividers

Using packaging inserts, partitions, and dividers can greatly enhance the stability of your products within their boxes. These elements are crucial for preventing movement that can lead to damage:

- Inserts: These are molded or cut to fit the contours of your product, holding it snugly in place.

- Partitions and Dividers: These help organize the package and add an additional layer of separation and protection, especially useful for packages containing multiple items or products that must not touch each other.

Optimize the Structural Design of Your Packaging

The shape and size (structural design) of your packaging play a critical role in how well your products are protected:

- Custom Fit: Design your packaging to precisely fit your product with enough room for protective materials but not so much that items can shift around.

- Material Selection: Use the appropriate materials that provide enough strength and cushioning to protect your products from shocks and impacts.

Don’t Cut Corners on Quality

Selecting high-quality packaging materials can prevent a lot of issues down the line:

- Material Durability: Choose materials that can withstand the pressures of shipping and handling without degrading or failing.

- Quality vs. Cost: While it’s tempting to go for the cheapest options, investing in higher quality materials can reduce the need for costly replacements and avoid damage to your products. Learn more about cost vs protection.

Utilize Edge Protectors for Extra Support

Edge protectors can reinforce the corners and edges of your packages, which are often the first to suffer damage:

- Protection and Stability: Edge protectors keep the package shape intact and protect against impacts and crushing forces.

- Material Options: Common materials for edge protectors include paperboard and plastic, each offering different levels of protection and recyclability.

Use the Right Tape for Your Application

Choosing the appropriate tape is crucial for ensuring that your packages remain sealed and intact throughout their journey:

- Tape Quality: High-quality tape will secure your packages without peeling off or tearing easily.

- Application Specifics: Consider the environment your packages will be exposed to, such as cold or humid conditions, and choose tape that can handle these environments effectively.

Select and Use the Right Stretch Film

Stretch film wraps help hold your packages together on a pallet, providing stability and protection against dust, moisture, and movement:

- Film Type: Choose between cast and blown stretch films depending on your needs—blown film is typically more resistant to puncture and tear.

- Additives: Consider films with UV protection or anti-static properties if your products require these features.

Label Your Packaging Clearly

Proper labeling not only helps with handling and shipping but can also reduce the risk of mishandling:

- Informational Labels: Include handling instructions, product descriptions, and any necessary warnings to ensure proper treatment during transit.

Consider Cushioning Products

Cushioning materials can absorb shocks and protect your products from impacts and vibrations:

- Types of Cushioning: Options include bubble wrap, foam inserts, air pillows, and packing peanuts, each suitable for different types of products and levels of protection.

Test Your Packaging Material and Products

Conducting tests according to standards set by organizations like the International Safe Transit Association (ISTA) ensures your packaging can withstand typical handling and shipping conditions:

- Testing Standards: Follow established testing protocols to simulate shipping and handling stresses on your packaging to see if they meet the required durability standards.

Conclusion: Ensuring Optimal Package Protection

By implementing these strategies, you can significantly enhance the protection of your products throughout the supply chain. From choosing the right materials and designs to employing protective inserts and rigorous testing, each step plays a vital role in safeguarding your items against potential damage. Collaborate with packaging experts like Brown Packaging to tailor solutions that meet your specific needs and improve the resilience of your packaging systems.

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

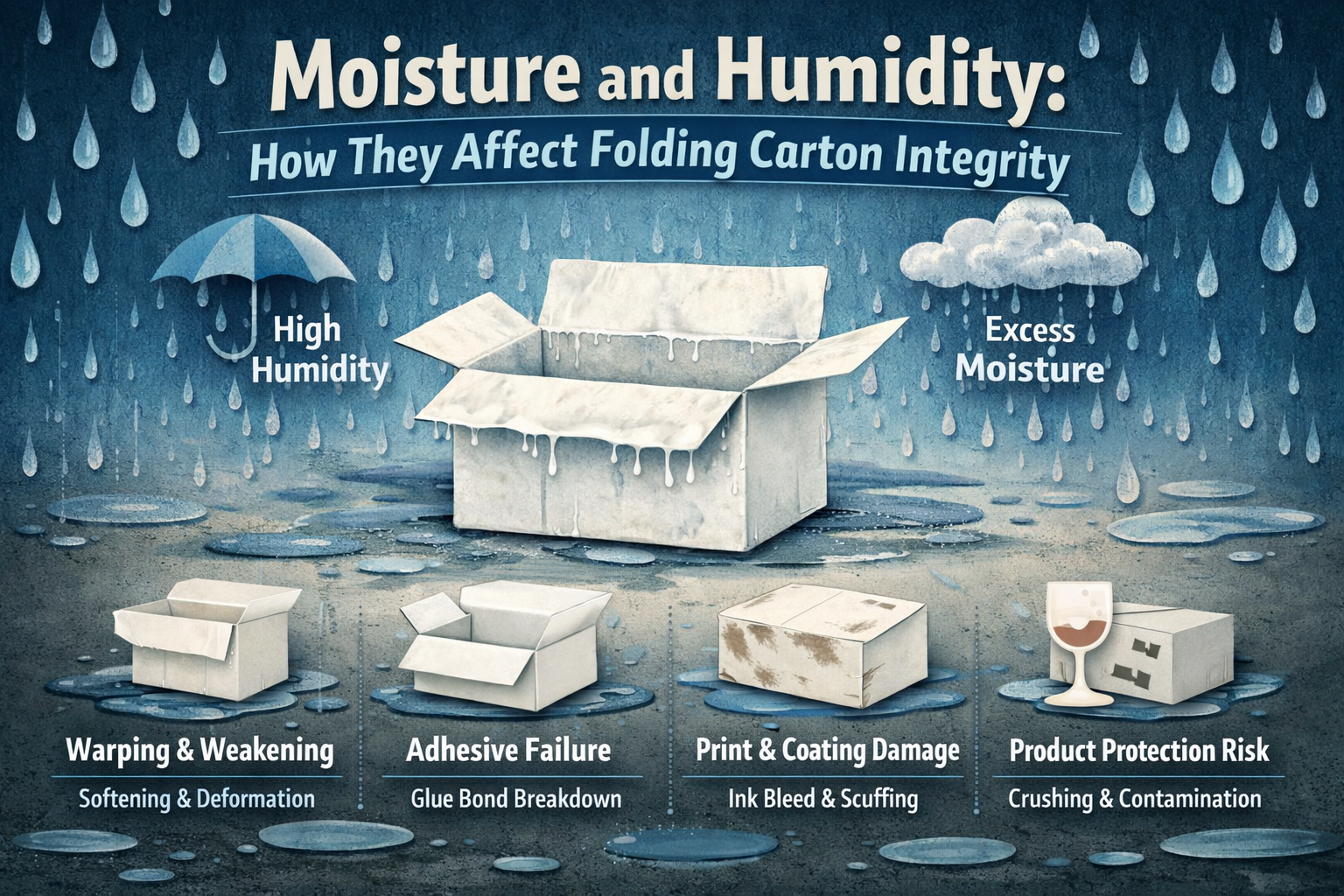

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Home » How To Protect Your Packages In a Supply Chain Environment

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss,