Home » How To Organize with Corrugated Bin Boxes

How To Organize with Corrugated Bin Boxes

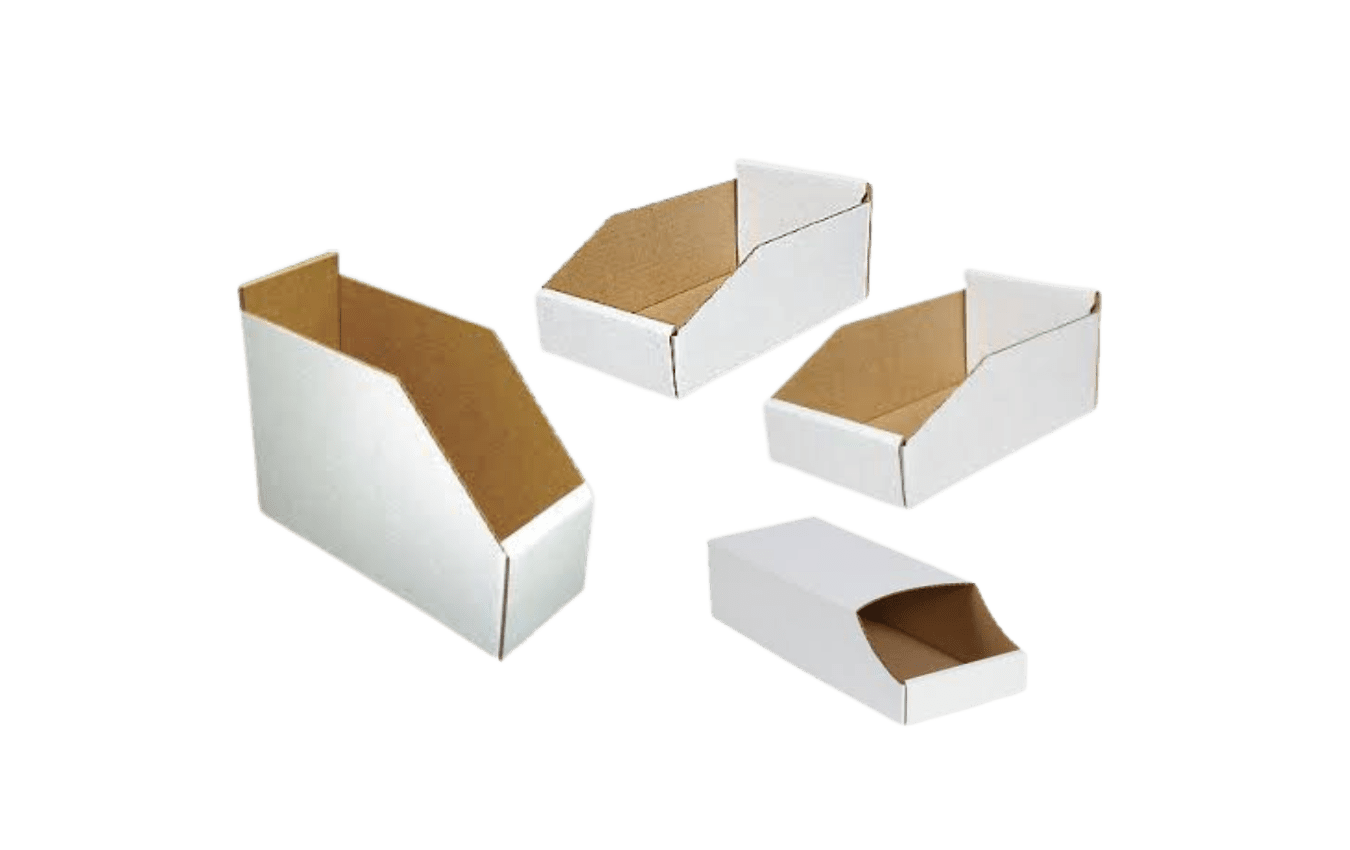

In the sprawling universe of storage solutions, corrugated bin boxes often go unnoticed. These unsung heroes of organization have a lot to offer when it comes to keeping products organized, safe, and easily accessible. Whether you’re running a business or just looking for ways to declutter your space, corrugated bin boxes might just be the answer to your organizational needs.

What are Corrugated Bin Boxes?

Before diving into their benefits, let’s understand what they are. Corrugated bin boxes, often made from corrugated fiberboard, are storage containers designed for storing, organizing, and categorizing small to medium-sized items. You might have seen them in workshops, warehouses, or even craft rooms.

Benefits of Using Corrugated Bin Boxes

- Durability and Strength: Made from corrugated fiberboard, these boxes have a unique fluted structure that offers strength and resilience. They can hold heavy items without collapsing, and their durability ensures they last a long time.

- Customizable: These boxes come in various sizes and can be tailored to fit specific spaces or needs. Some suppliers even offer custom printing, so businesses can brand their storage solutions or add labels for better organization.

- Eco-friendly: Since they are primarily made from recycled materials, corrugated bin boxes are a green choice. And when they’ve reached the end of their lifespan, they’re 100% recyclable!

- Cost-effective: In comparison to plastic bins or metal storage systems, corrugated bin boxes tend to be more affordable. This makes them an ideal choice for businesses that need bulk storage solutions.

- Space-efficient: Their design allows for easy stacking, saving floor space. When labeled properly, products can be found and accessed quickly, increasing efficiency and productivity.

- Protection: Corrugated boxes provide a buffer against external forces. Their structure allows for some cushioning which can protect the contents from minor impacts.

Applications and Uses

- Retailers: Corrugated bin boxes can keep backstock organized, making inventory management a breeze.

- Warehouses: These boxes are perfect for categorizing parts or products, making it easy for workers to locate and pick items.

- Craft rooms: Artists and crafters can store beads, buttons, threads, and other small items, keeping their workspace tidy and their materials easily accessible.

- Garages: These boxes can be used to organize tools, nuts, bolts, and other small parts, ensuring that everything has its place.

Tips for Effective Use

- Labeling is Key: Always label your boxes. It helps in quick identification and retrieval of items. Consider using large, clear labels and possibly color-coding for different categories.

- Regularly Review Contents: Periodically check the contents of your boxes. Remove any items that are no longer needed, and make sure everything in the box belongs there.

- Keep Like Items Together: Group similar items or those that are used together. For instance, if you’re using boxes in a workshop, keep all screws in one box and nails in another.

- Consider Shelving: To maximize the benefits of these boxes, consider using shelving units. This elevates the boxes, making them easier to access and saving floor space.

In conclusion, corrugated bin boxes are an exceptional organizational tool. Their versatility, durability, and cost-effectiveness make them a top choice for both businesses and individuals. The next time you find yourself drowning in clutter or struggling to streamline your inventory, consider the humble corrugated bin box. It might just be the organizational magic you’ve been searching for.

If you are interested in corrugated bin boxes, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Home » How To Organize with Corrugated Bin Boxes

Gift-giving is a timeless tradition, and the packaging plays a crucial role in making the gesture even more special. When it comes to choosing the

In the world of packaging, there’s a constant pursuit of innovation and improvement to ensure products are not only securely packaged but also easy to

In the world of packaging, there’s a constant pursuit of innovation and improvement to ensure products are not only securely packaged but also easy to