Home » How Packaging Design Can Affect Your Freight Costs

How Packaging Design Can Affect Your Freight Costs

There are many factors that can contribute to the cost of packaging with freight being no exception. Freight is the process of transporting your product from the manufacturer/distributor to the customer.

Generally, freight costs consist of labor, mileage, fuel, wear and tear on a vehicle, special requirements (if applicable) and a company’s markup. These costs can be influenced by a variety of factors including external factors and a packaging design.

For this blog, we will cover how packaging design can affect your freight costs and provide you with solutions to help alleviate these costs. Packaging design is how your packaging is built and shaped. This includes the weight of your package, structural integrity and dimensions.

Packaging design can affect your freight costs by:

Weight

The weight of your package can dictate how much you pay for freight costs, as some carriers may charge by weight of the load in addition to mileage. This is because heavier cargo requires more cost in fuel and often slows down transportation. Slower transportation results in higher costs of labor. In addition, trucks are limited to carry a certain amount of weight, which may require your loads to be transported separately or by multiple trips if needed.

In addition, sea and air transportation usually charge by volumetric weight and distance traveled.

In some cases, packaging material is not heavy enough to affect the total weight. However, if you would like to minimize the risk, then you want to resort to lighter packaging solutions such as plastic, chipboard, or paperboard products. Perhaps, you may want to look into your carrier’s shipping options and pick the best option that aligns closest to your packaging needs.

You may want to also work with a packaging expert that can help you reduce the weight of your packaging design, while maintaining the structural integrity of your packaging.

Structural Design

The structural design will impact the way it is shipped, which may also influence the cost of freight. A package’s structural design consists of the packaging size (length, width and height) in addition to how the packaging will fold together.

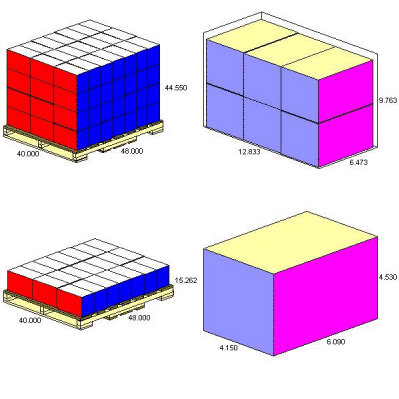

Typically, a finished packaged product or packaging material orders are usually shipped on a pallet. The shape and size of your pallet can influence how much you can fit in a truck, plane, or naval ship. For example, if the packaging has non-uniformed edges, then it will take up more surface area. In addition, packaging that is not easily foldable or stackable can cause an issue in how much inventory you can transport at one time.

Irregular shaped pallets can accrue additional cost by adding extra trips, which can contribute to more labor, fuel and other costs. Not to mention, the purchasing of stronger stretch film to hold the merchandise more securely.

To solve this issue, it is recommended that you carefully design your product to an optimal structure. In addition, you can better allocate your packages via transportation with CAPE software. CAPE enables you to optimize your pallet and truck loads to maximize your efficiency. This may warrant you to work with a packaging specialist.

Structural Integrity

The structural integrity plays a huge role in the success of your packaging project. It ensures that your product will get to the end user presentable, undamaged, and within standard. However, this is not always the case as packaging and products inside can become damaged with wear and tear, as they are vulnerable to external environments. Wear and tear is eventually going to happen, however it can be limited or postponed with a proper packaging design and material selection.

Packaging can become secure with adequate material strength and thickness. Inserts, dividers and edge protectors help hold your product in place during shipment. Despite these being additional costs, it may greatly reduce your product loss, which will offset your investment.

In addition, it is important to keep in mind if your product will require special handling during transport. As some products such as food, beverage, and pharmaceuticals are sensitive to specific temperatures, which can cause them to become spoiled. Ultimately, this may require you to receive some cold chain packaging solutions.

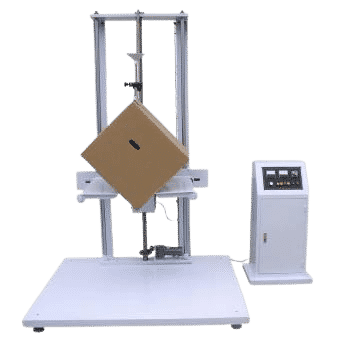

To help prevent product loss, you should get your product tested prior to mass producing it. Some tests may offer you certification and quality assurance such as the compression, drop, vibration, and environmental simulation. Furthermore, you want to be sure that the material you use to hold your products can support your product’s weight.

Summary: Packaging Design and Freight Costs

Ultimately, your packaging design has a very direct influence on freight costs. To avoid these additional costs it is important to be mindful of your packaging’s weight, structural design and structural integrity. To best address each of these potential issues on freight costs, you should reach out to your packaging specialists.

If you are interested in stock or custom packaging solutions and would like the most optimal packaging design, then contact Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » How Packaging Design Can Affect Your Freight Costs

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In

Saving on the purchase of corrugated boxes involves strategic planning and smart sourcing to ensure you get the best value without compromising on quality. By

Packaging isn’t just a box or a bag—it’s a line item on your budget, a touchpoint with your customer, and a critical part of your