Home » Heat Seal Vs Cold Seal Packaging: Which Should You Choose?

Heat Seal Vs Cold Seal Packaging: Which Should You Choose?

Choosing the right sealing method impacts product quality, cost, durability, and speed to market. The two most common options—heat seal and cold seal—each have distinct strengths and limitations. By understanding how these methods differ, buyers can select the most effective solution for food, medical, industrial, and consumer products.

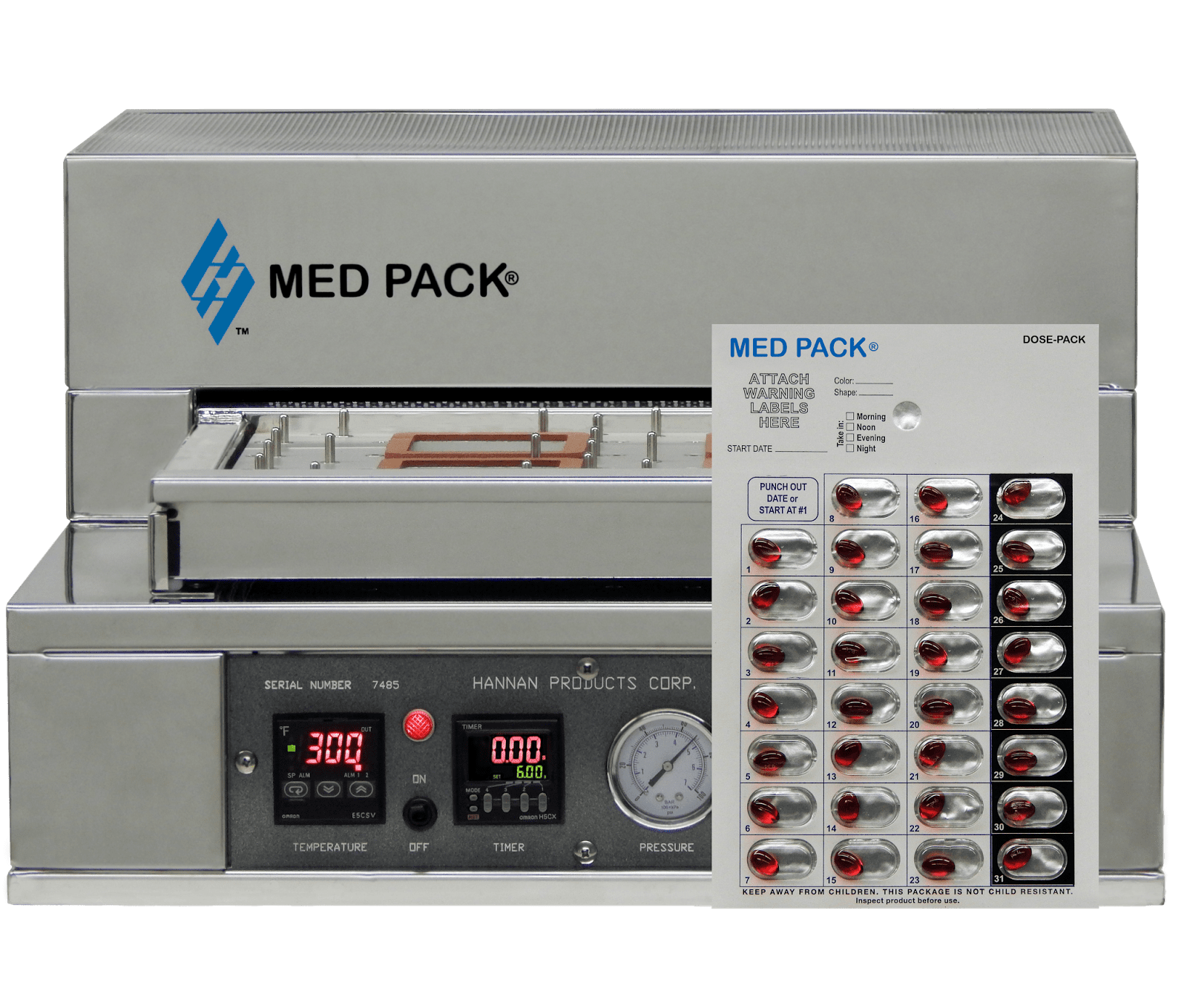

What is Heat Seal?

Heat seal packaging uses heated surfaces to melt the sides of a film or a sealant coating together. This creates a tight, durable closure that resists outside elements. Because it supports multi-layered films with barrier properties, heat seal remains one of the most widely used sealing methods.

Applications

Heat seal is often used for snacks, dry goods, frozen foods, and pasta. In addition, medical devices, electronic components, and industrial items such as screws or fittings are frequently packaged this way. These products are typically sealed in pouches, sachets, plastic bags, or blister packs.

Advantages

Provides strong seals resistant to chemicals, moisture, and harsh environments.

Creates a tamper-evident closure.

Works without adhesives.

Disadvantages

However, high temperatures can damage products such as chocolate or ice cream.

Production requires precise monitoring of time, temperature, and pressure.

Sealing speed is up to 10 times slower than cold seal.

Heated machinery increases the risk of burns and workplace injuries.

What is Cold Seal?

Cold seal packaging bonds film surfaces by applying a cohesive coating that sticks only to itself when pressure is added. Since heat is not required, this process is faster and well suited for products sensitive to high temperatures.

Applications

Cold seal is common for chocolates, ice cream, pharmaceuticals, baked goods, flammable items, and other temperature-sensitive products. Packaging formats include pouches, roll stock, chipboard cartons, clamshells, and blister packs.

Advantages

Much faster than heat seal because no warm-up is needed.

Protects heat-sensitive products.

Easier to open, enhancing consumer convenience.

Disadvantages

However, seal strength is lower than heat seal.

Requires cohesive material, adding cost.

Not chemical resistant, limiting use in some food and beverage applications.

Which Method Should You Choose?

Heat seal provides maximum strength, durability, and tamper resistance, making it ideal for applications that demand barrier protection. In contrast, cold seal offers higher production speed and protects heat-sensitive products, though with reduced strength. Ultimately, the choice depends on your product type, performance requirements, and fulfillment environment.

Sealing Solutions with Brown Packaging

Whether you need the superior durability of heat seal or the speed and temperature protection of cold seal, Brown Packaging delivers customized solutions to match your application. Contact us today to get started.

References

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

FDA. (2023). Food Contact Substances and Packaging Materials Guidance. U.S. Food and Drug Administration.

Fibre Box Association. (2022). Sealing and Packaging Methods Overview. Retrieved from https://www.fibrebox.org

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Heat Seal Vs Cold Seal Packaging: Which Should You Choose?

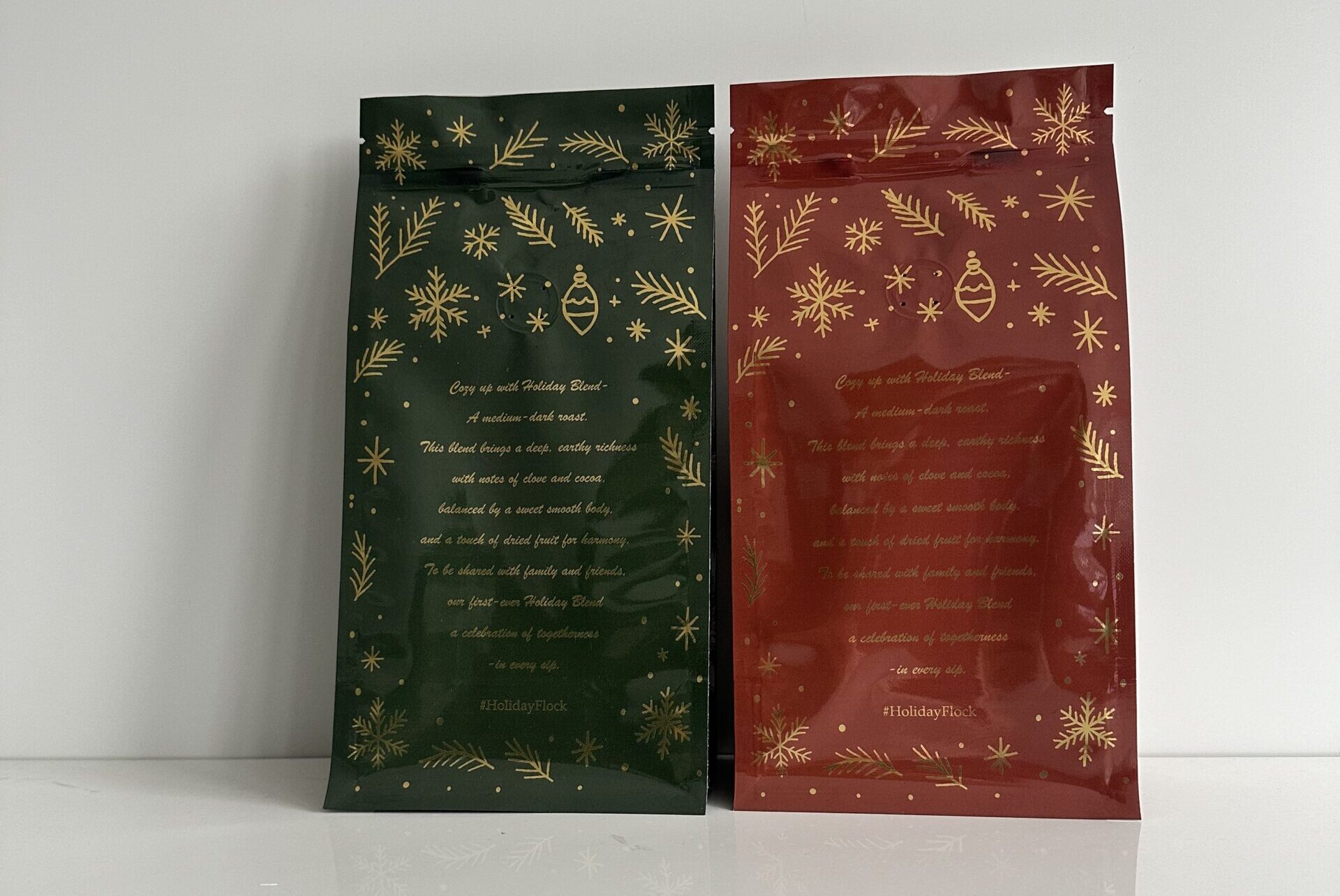

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Packaging plays a crucial role in safeguarding products from various hazards that can compromise their quality, safety, and integrity. From the manufacturing floor to the

In today’s crowded marketplace, where consumers are overwhelmed with choices, establishing differentiation is crucial for any brand’s success. One of the most effective ways to