Home » Full Overlap (FOL) Corrugated Boxes: Shipping Durability and Security

Full Overlap (FOL) Corrugated Boxes: Shipping Durability and Security

When it comes to shipping, choosing the right type of box can make a significant difference in protecting the contents and ensuring they arrive safely at their destination. Among the various styles of corrugated boxes available, Full Overlap (FOL) boxes stand out as an especially robust option. This blog post explores the design, advantages, and common uses of Full Overlap corrugated boxes in the shipping industry.

Understanding Full Overlap (FOL) Corrugated Boxes

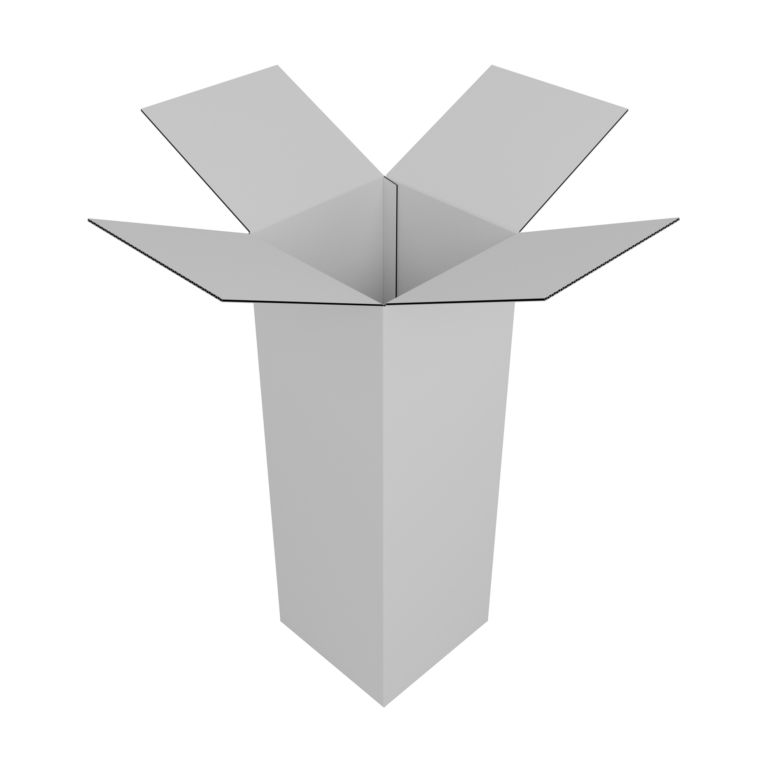

Full Overlap boxes, commonly abbreviated as FOL, are a type of corrugated box where the outer flaps overlap the entire width of the box. This design feature provides extra strength and durability, making these boxes particularly suitable for heavy or fragile items.

- Design Characteristics: The defining feature of FOL boxes is that the top and bottom flaps completely overlap each other, providing an additional layer of corrugated cardboard over the entire top and bottom. This design results in a highly sturdy and uniform surface.

Why Choose FOL Corrugated Boxes for Shipping

FOL boxes are preferred for several reasons, particularly when it comes to shipping items that require extra protection.

Enhanced Strength and Durability:

- The overlapping flaps provide increased strength and rigidity, making the box more resistant to crushing when stacked.

- The uniform surface is ideal for absorbing impacts during transit, reducing the risk of damage to the contents.

Ideal for Heavy or Irregular Items:

- FOL boxes are well-suited for packaging heavy objects or items with irregular shapes. The extra strength ensures that the box maintains its integrity under the weight.

- The design accommodates objects that may put pressure on the sides of the box, as the full overlap offers added resistance against bursting.

Improved Security:

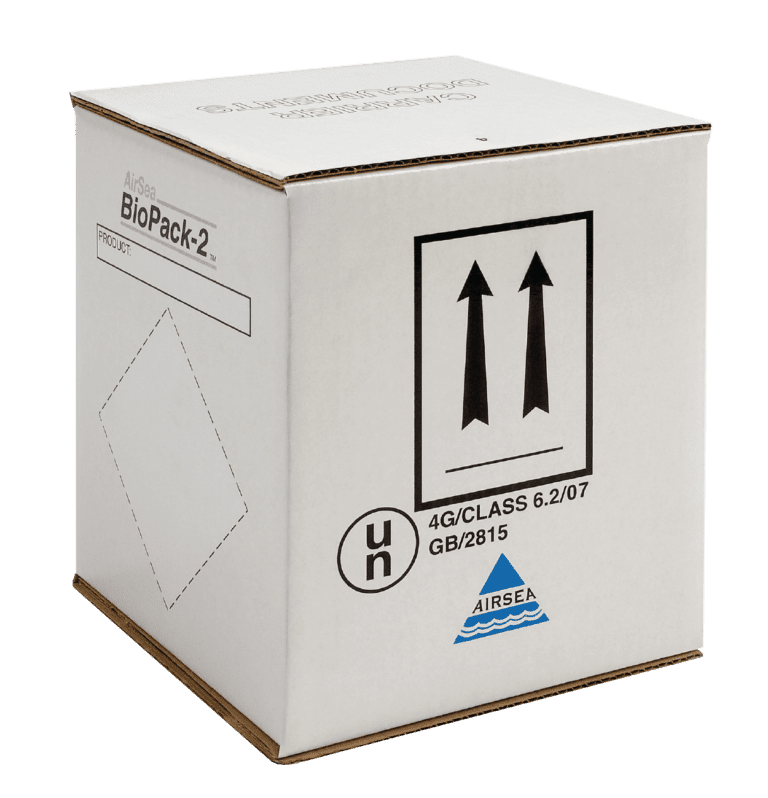

- The overlapping flaps create a more secure closure, which is beneficial for valuable or sensitive items.

- They can be easily sealed with tape, staples, or strapping, adding an extra layer of security during shipping.

Versatility in Use:

- FOL boxes can be used for a variety of products across different industries, including electronics, automotive parts, home goods, and more.

- They are adaptable to various sizes and weights, making them a versatile choice for businesses with diverse shipping needs.

Customization Options

Like other corrugated boxes, FOL boxes offer several customization options to meet specific shipping requirements.

- Material Choices: Available in various flute sizes and types of corrugated material, allowing for customization based on the level of protection needed.

- Printing and Branding: FOL boxes provide ample space for printing and branding, making them an effective tool for marketing and brand recognition.

- Size Adaptability: They can be manufactured in a wide range of sizes, accommodating different product dimensions.

Sustainability Considerations

With growing environmental concerns, FOL boxes also present a sustainable packaging option.

- Recyclable Materials: Many FOL boxes are made from recycled materials and are themselves fully recyclable, aligning with eco-friendly business practices.

- Reduced Material Usage: The design of FOL boxes can minimize the need for additional internal packaging materials, such as bubble wrap or foam peanuts, further reducing environmental impact.

If you are interested in full overlap corrugated boxes, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Full Overlap (FOL) Corrugated Boxes: Shipping Durability and Security

Selecting the right board option for your packaging needs is critical to ensuring product protection, cost efficiency, and customer satisfaction. However, with various materials and

Corrugated boxes are more than mere containers; they’re the culmination of engineering, design, and environmental consideration. This advanced guide delves into the nuances of corrugated

When it comes to packaging solutions, corrugated boxes offer versatility and protection. Among the common corrugated box styles are the Regular Slotted Container (RSC) box