Home » Folding Carton Vs Rigid Boxes: Which One Should You Choose?

Folding Carton Vs Rigid Boxes: Which One Should You Choose?

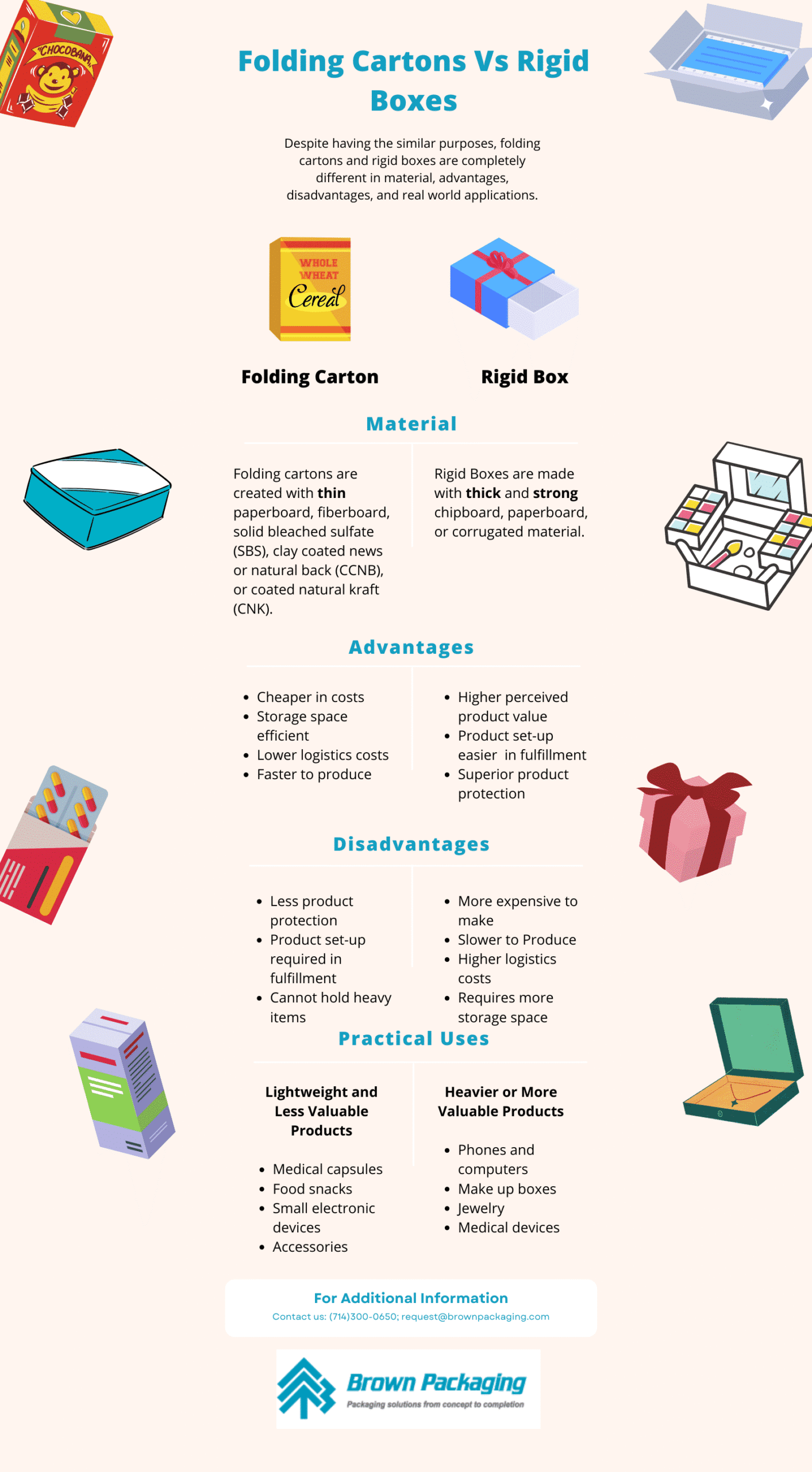

When it comes to packaging your products, the choice between folding cartons and rigid boxes is crucial. Both types serve similar purposes in protecting, displaying, and promoting products but differ significantly in their construction and usage implications. This guide provides an in-depth comparison to help you decide which packaging solution best suits your product plans, budget, and business goals.

Understanding Folding Cartons and Rigid Boxes

What is A Folding Carton?

Folding cartons are typically made from thin paperboard, precisely cut, folded, and glued to form a variety of shapes and sizes. These cartons are versatile, customizable, and widely used across various industries for lightweight, durable, and cost-effective packaging solutions.

Folding Carton Benefits

• Cheaper in costs: folding cartons are less complex and are generally made with cheaper material than rigid boxes.

• Storage space efficient: cartons have the flexibility of folding flat, which makes it ideal for storage purposes.

• Lower logistics costs: with lightweight material and a flat structure, cartons are cheap in overhead for shipping and handling.

• Faster to produce: typically, the simpler the packaging product is the faster it is able to be produced.

Folding Carton Disadvantages

• Less product protection: the material used to create folding cartons are thinner compared to rigid boxes.

• Product set-up required in fulfillment: packagers usually have to fold the carton into its form.

• Cannot hold heavy or fragile items: this type of box is not recommended in holding fragile or heavy items.

Common Folding Carton Applications

• Food snacks

• Cereal

• Small electronic devices and accessories

• Soda packs

• Medicine

• Consumer goods (small)

• Sports accessories

• Nutrition and supplements

• Ink cartridges

What is A Rigid Box?

Rigid boxes are made from heavier cardboard than folding cartons and are non-collapsible. Known for their strength and premium quality, these boxes offer enhanced protection and an elevated unboxing experience, often used for luxury or high-value products.

Rigid Box Benefits

• Higher perceived product value: rigid boxes provide customers with more confidence due to your investment in the products packaging (display and promotion)

• Product set-up is easier in fulfillment: these boxes are delivered in their box shape, which will require less labor in fulfillment.

• Superior product protection: these boxes provide extra protection compared to other boxes.

Rigid Box Disadvantages

• More expensive to make: the cost of materials and effort to make rigid boxes is substantially more than a folding carton.

• Slower to Produce: these boxes are more complex, which often result in slower production.

• Higher logistics costs: these boxes are not as logistic friendly as cartons.

• Requires more storage space: boxes have to be stacked and cannot lay perfectly flat like a foldable box.

Common Rigid Box Applications

• Gift boxes

• Cosmetic and beauty set boxes

• Medical devices

• High-end and luxury products

• Jewelry

• Smartphones and computers

Comparison and Considerations

When choosing between folding cartons and rigid boxes, consider the following aspects:

- Product Type: The nature of the product, its fragility, and value play crucial roles. Rigid boxes are preferable for delicate or premium items, while folding cartons are sufficient for more durable and lower-value products.

- Budget Constraints: Folding cartons are more budget-friendly, especially for large volumes, making them suitable for businesses looking to minimize costs.

- Brand Image: The packaging contributes significantly to brand perception. Rigid boxes often convey a higher quality image, appropriate for luxury brands or premium product lines.

- Environmental Impact: Consider the sustainability of your packaging choice. Both options can be produced with recycled materials, but the overall environmental impact may vary based on the production process and materials used.

Final Recommendation

Your decision should align with your overall marketing strategy, product requirements, and customer expectations. If presenting a luxury image or ensuring the utmost protection is crucial, rigid boxes are the best choice. However, if cost efficiency and practicality are more significant concerns, folding cartons will serve well.

If you are interested in rigid boxes or folding cartons, then partner with Brown Packaging today to get started.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Folding Carton Vs Rigid Boxes: Which One Should You Choose?

Functional features like tear strips, windows, and hang tabs can enhance consumer experience and retail appeal—but they also introduce engineering challenges. Each modification affects structural

High-speed automated packaging lines can run hundreds of cartons per minute, but only if the carton’s design and material are optimized for smooth feeding, folding,

Board caliper—the thickness of paperboard—directly influences carton strength, folding behavior, print quality, and cost. Selecting the right caliper is a balancing act between performance requirements