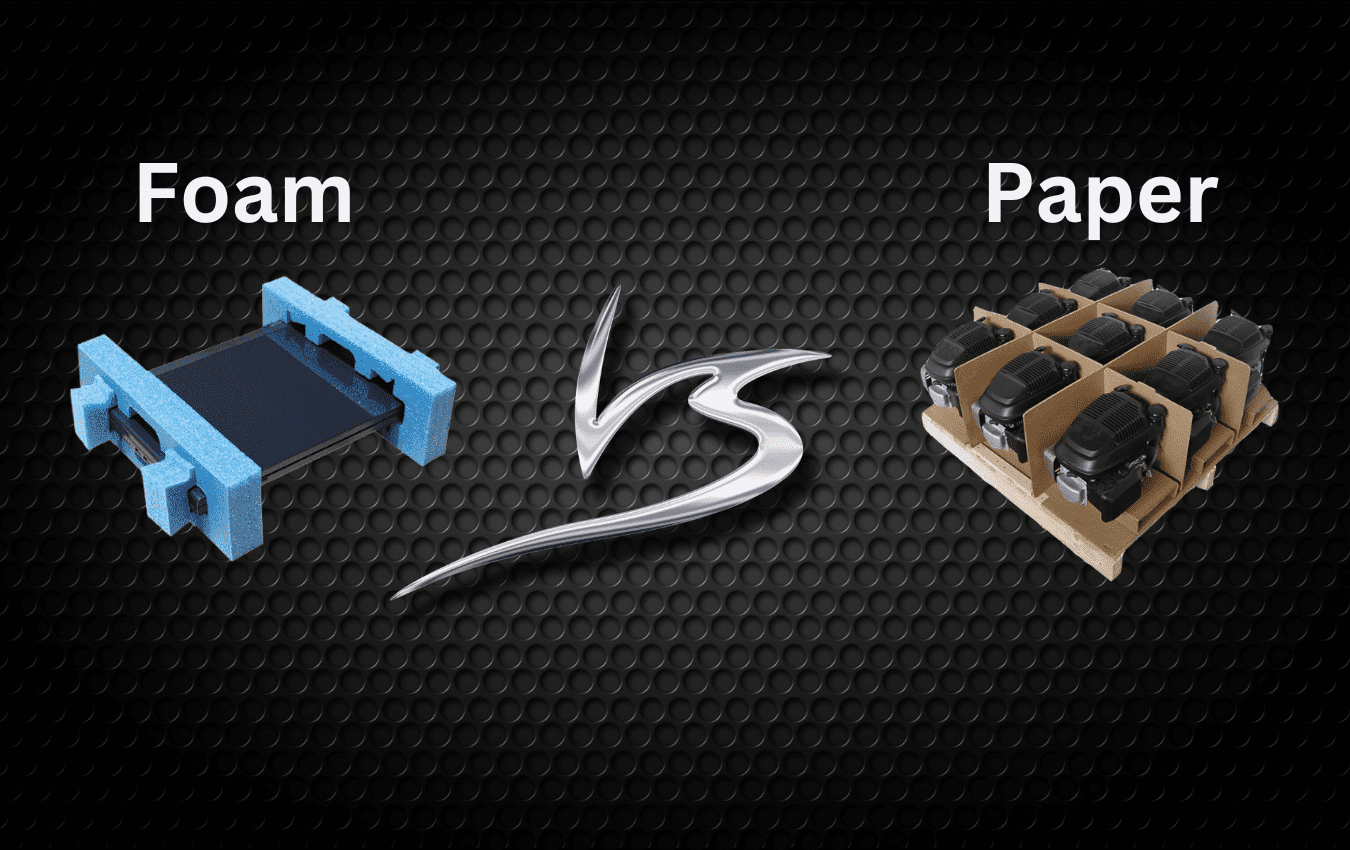

Home » Foam vs. Paper: Comparing Protective Packaging Materials

Foam vs. Paper: Comparing Protective Packaging Materials

In the world of e-commerce and supply chain management, the need for reliable packaging materials cannot be overstated. From the careful encasing of fragile items to ensuring the safe transit of products, the choice of packaging material often makes a significant difference. In this blog, we delve into the world of protective packaging materials, comparing two popular options: foam and paper.

Understanding Protective Packaging

Before we compare foam and paper, it’s important to understand what protective packaging entails. Protective packaging, as the name suggests, is designed to shield products from damage during storage or transit. This damage could come in many forms such as shock, vibration, abrasion, or environmental factors such as moisture or temperature fluctuations.

Foam Packaging: Advantages and Disadvantages

Advantages of Foam Packaging

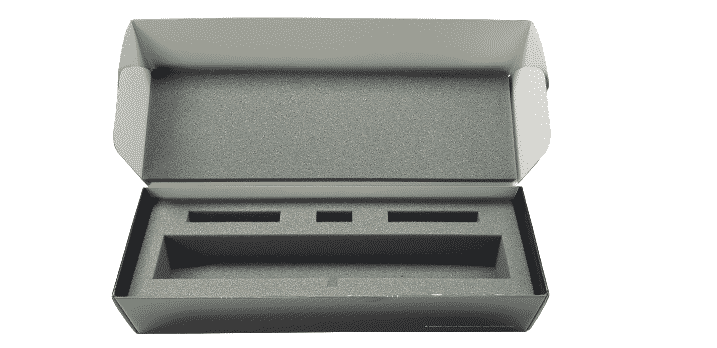

Superior Cushioning

Foam is known for its exceptional cushioning properties. It’s capable of absorbing and dispersing impact, which reduces the risk of damage to fragile or sensitive items. This makes it a favored choice for electronics, ceramics, glassware, and other delicate items.

Versatility

Foam can be customized into different shapes and sizes, making it a versatile choice for different products. This adaptability means it can be tailored to fit unusual shapes or to snugly encapsulate specific items.

Lightweight

Foam is extremely light, which can help reduce shipping costs. This lightweight property doesn’t compromise its protective capabilities, though, as foam still offers excellent shock absorption.

Disadvantages of Foam Packaging

Environmental Impact

One of the major disadvantages of foam is its environmental impact. Foam is typically non-biodegradable and can take hundreds of years to decompose. Even when recycled, the process can be energy-intensive.

Cost

Compared to other packaging materials, foam can be relatively expensive. The cost of foam packaging includes not only the material itself but also the cost associated with its disposal or recycling.

Paper Packaging: Advantages and Disadvantages

Advantages of Paper Packaging

Eco-Friendly

Paper packaging stands out for its environmental friendliness. It is biodegradable and easily recyclable, causing much less environmental harm compared to foam. Additionally, many paper packaging options are made from recycled materials.

Cost-Effective

Paper is generally less expensive than foam. Its cost-effectiveness combined with its eco-friendliness makes it a popular choice for businesses conscious about their budget and environmental footprint.

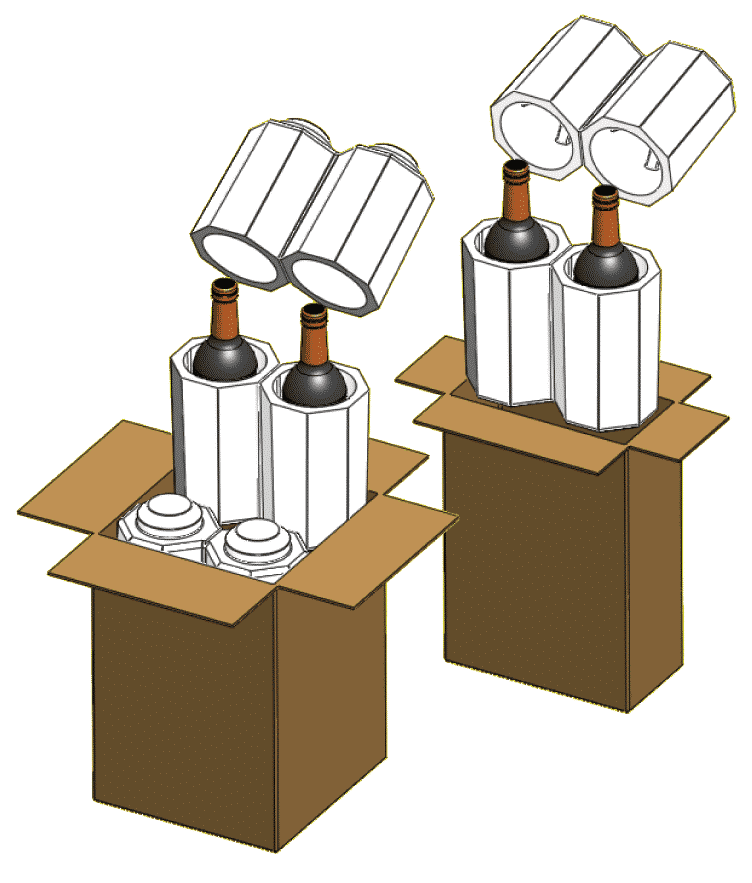

Versatility

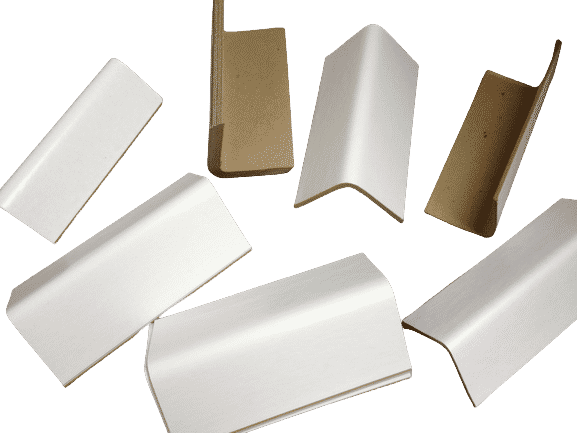

Just like foam, paper can be adapted into different forms to cater to different packaging needs. Corrugated paper, Kraft paper, tissue paper, and more offer varying levels of protection and can be customized to fit different products.

Disadvantages of Paper Packaging

Lower Cushioning

While certain forms of paper packaging, like corrugated, offer reasonable cushioning, they often don’t match the shock-absorbing qualities of foam. This makes paper less suitable for extremely fragile items.

Susceptibility to Environmental Factors

Paper is more susceptible to environmental factors like moisture, which could potentially harm the product inside.

So, Foam or Paper?

The choice between foam and paper for protective packaging depends largely on the specific requirements of the product to be packaged, the company’s budget, and its sustainability goals.

If the product is highly fragile or sensitive, foam might be the preferred option for its superior cushioning properties. However, for companies with strong eco-friendly policies or for less fragile products, paper packaging might be a better choice due to its biodegradability, recyclability, and cost-effectiveness.

In conclusion, both foam and paper have their place in the world of protective packaging. Understanding the benefits and drawbacks of each can help businesses make informed decisions that align with their operational needs and environmental responsibilities. As sustainability continues to become a more prominent factor in consumer choice, it’s likely that we’ll continue to see innovations in both these spaces to further enhance their protective qualities and environmental credentials.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Foam vs. Paper: Comparing Protective Packaging Materials

In the world of packaging, the visual appeal of your product plays a significant role in catching the customer’s eye and leaving a lasting impression.

With rising tariffs, unpredictable freight costs, and ongoing supply chain delays, more companies are pulling away from overseas packaging and turning to U.S.-based corrugated box

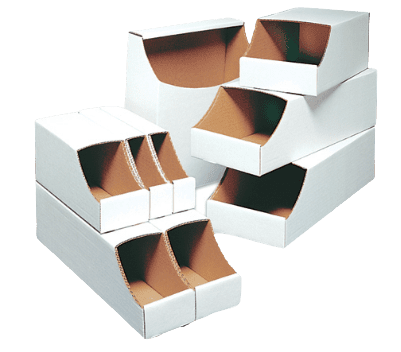

Corrugated bin boxes are widely used for storage and organization, especially in warehouses and retail settings. When used and stacked properly, they offer an efficient