Home » Factors Influencing the Cost of Custom Corrugated Boxes

Factors Influencing the Cost of Custom Corrugated Boxes

Custom corrugated boxes are a staple in the packaging industry, serving as a reliable means to protect and present various products. The cost of these boxes can vary significantly based on several factors. Understanding what influences the cost of custom corrugated boxes is crucial for businesses looking to strike a balance between quality and budget.

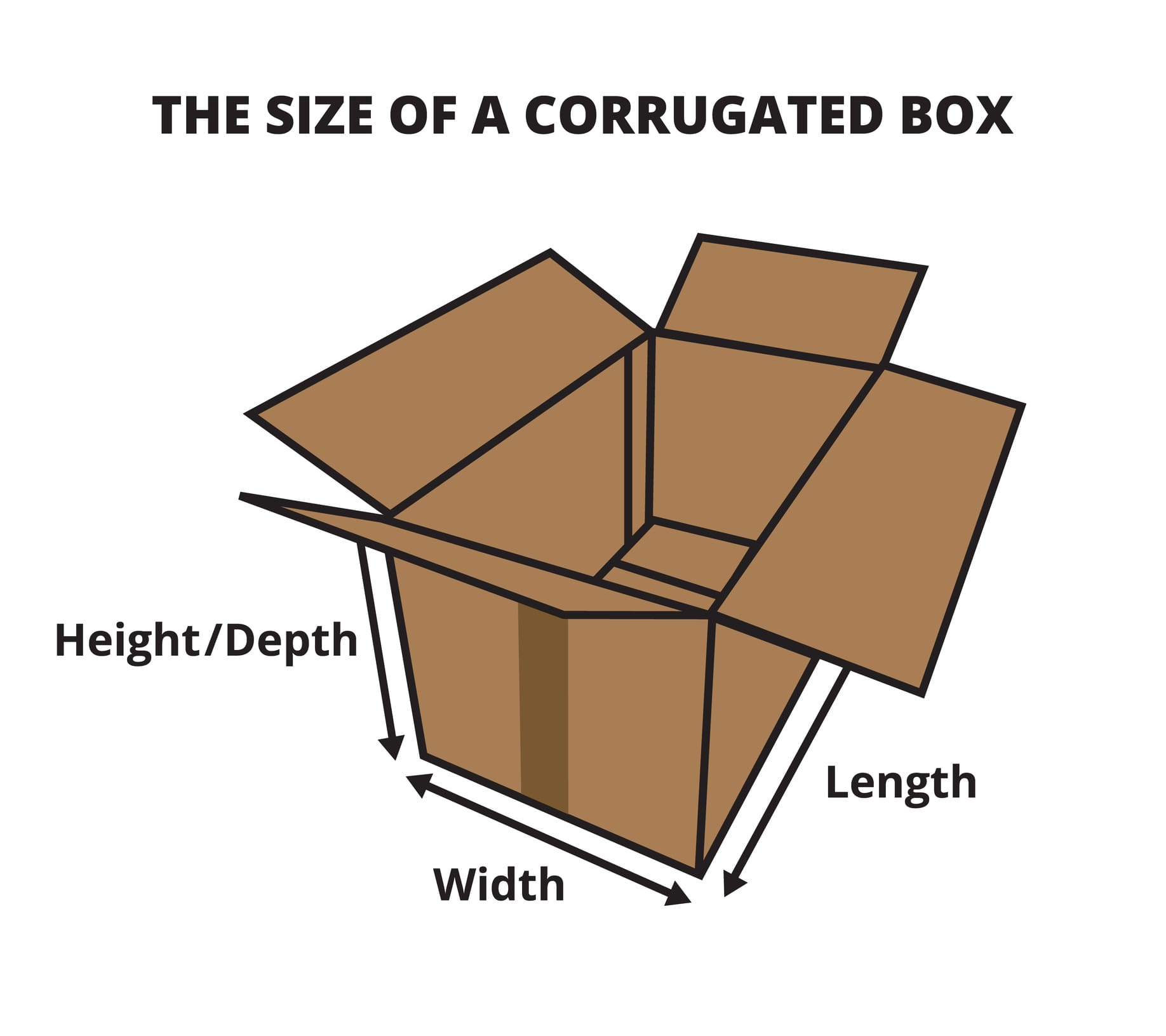

Box Size and Dimensions

The size and dimensions of custom corrugated boxes are perhaps the most fundamental factors affecting their cost. Larger boxes generally require more raw material (corrugated cardboard) and manufacturing time, resulting in higher costs. Conversely, smaller boxes are typically more affordable.

Box Style and Complexity

The style and complexity of the box design can greatly influence its cost. Custom boxes come in various styles, including regular slotted containers (RSC), tuck-top boxes, mailer boxes, and more. Intricate box designs with multiple flaps, unique openings, or custom die-cut shapes require specialized manufacturing processes and are usually more expensive than standard box styles.

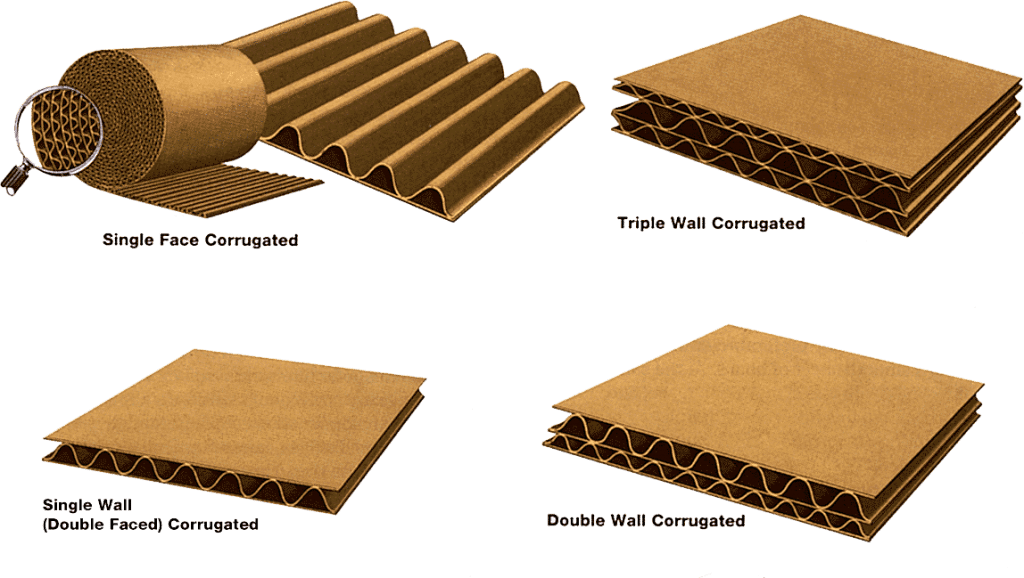

Material Quality

The type and quality of corrugated material used play a significant role in determining box cost. Corrugated cardboard comes in different grades, with single-wall, double-wall, and triple-wall being common options. Higher-quality, thicker material provides better structural integrity and protection but comes at a higher cost compared to thinner alternatives.

Printing and Customization

Customization options such as printing, branding, and special finishes can add to the cost of corrugated boxes. Full-color printing, embossing, foil stamping, and matte or gloss finishes all require additional processes and materials, making the boxes more expensive. However, these customization features can enhance the visual appeal and branding of the product.

Quantity and Order Volume

The quantity of custom corrugated boxes ordered has a direct impact on the cost per unit. Generally, ordering in larger quantities can lower the per-box cost due to economies of scale. Smaller orders, on the other hand, may incur higher unit costs as they are less efficient to produce.

Lead Time and Rush Orders

The lead time or turnaround time for custom box production can also influence costs. Rush orders often come with premium pricing because they require expedited production, potentially causing disruptions to the manufacturer’s regular schedule. Planning well in advance and avoiding rush orders can help keep costs down.

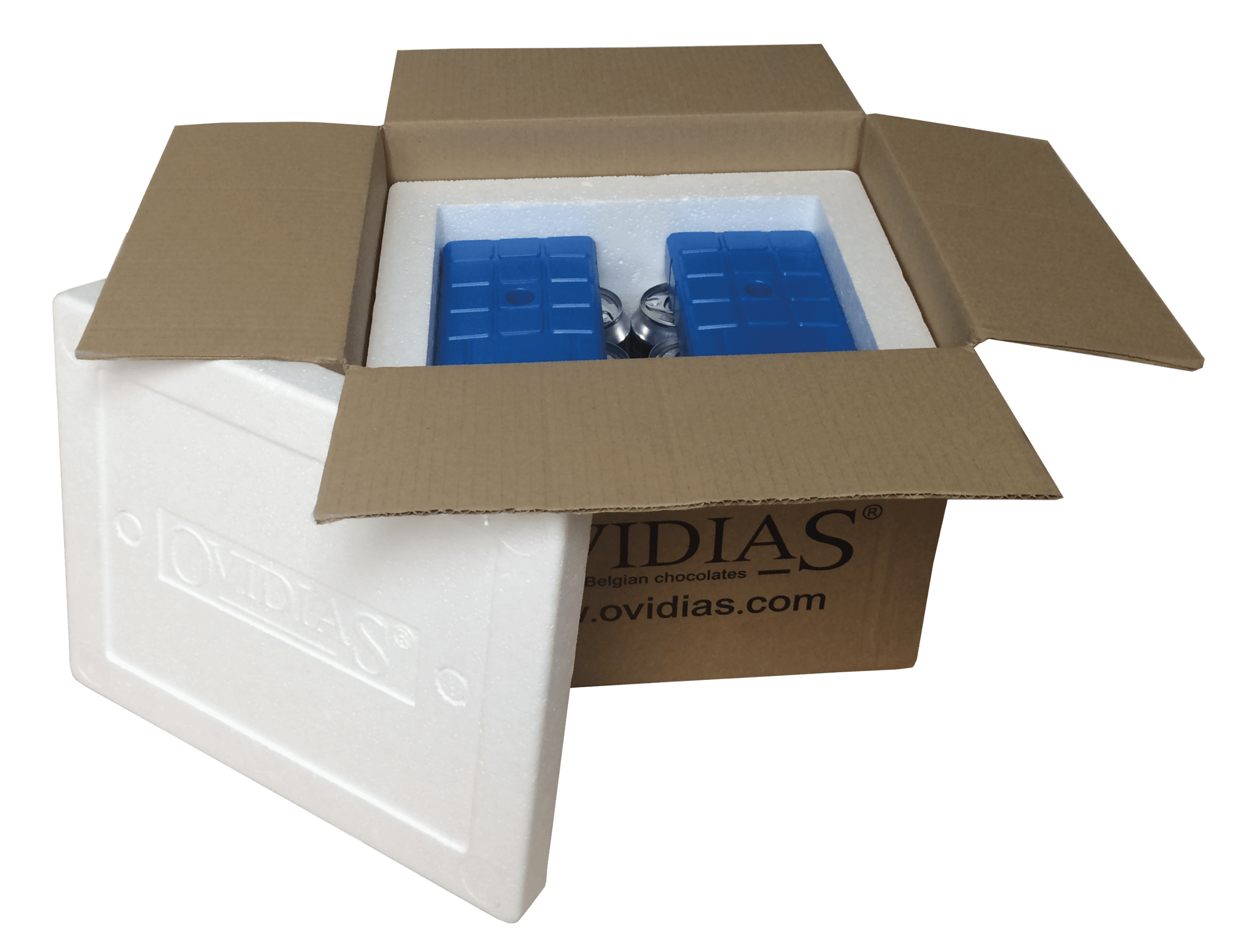

Special Features and Add-Ons

If you require special features or add-ons like handles, windows, or inserts within the corrugated boxes, be prepared for additional expenses. These features require extra materials, labor, and manufacturing time, contributing to higher costs.

Shipping and Handling Requirements

Consider the logistics and shipping requirements when calculating the overall cost of custom corrugated boxes. If your products need extra protection during transit, you might require additional inserts, padding, or even double-boxing, all of which can increase the total cost.

Environmental Considerations

As environmental awareness grows, more businesses are opting for eco-friendly packaging solutions. While sustainable materials and designs can contribute to higher upfront costs, they may attract eco-conscious consumers and reduce long-term environmental impact.

If you are looking for cost effective stock or custom corrugated boxes, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Factors Influencing the Cost of Custom Corrugated Boxes

Selecting the right board option for your packaging needs is critical to ensuring product protection, cost efficiency, and customer satisfaction. However, with various materials and

Why Custom Corrugated Boxes Remain a 2026 Essential Custom corrugated boxes continue to be the most relied-on packaging solution for industries ranging from industrial manufacturing

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength