Home » Exploring the World of Pouch Packaging Materials

Exploring the World of Pouch Packaging Materials

Packaging is an essential aspect of product design, as it helps to protect the contents and enhance their shelf life. One of the most versatile types of packaging is pouches, which can be used for a wide range of products, from food items to personal care products. Pouches are lightweight, portable, and come in various shapes and sizes. They are also customizable, allowing businesses to showcase their brand with unique graphics and designs.

The material used to make pouches can significantly impact their functionality and performance. In this blog, we will explore the different types of materials used to make pouches and their benefits and drawbacks.

Plastic Pouches

Plastic is one of the most common materials used to make pouches. It is versatile, durable, and lightweight, making it an ideal material for packaging. There are several types of plastic films used in the production of pouches, such as polyethylene, polypropylene, and polyester.

Polyethylene (PE) is a widely used plastic film that is suitable for packaging food items, such as snacks, baked goods, and frozen foods. It is affordable, has excellent moisture and oxygen barrier properties, and is easy to print on. Polyethylene films come in different thicknesses, with high-density polyethylene (HDPE) being more robust than low-density polyethylene (LDPE).

Polypropylene (PP) is another type of plastic film commonly used to make pouches. It is more durable than PE and has a higher melting point, making it suitable for hot-fill applications. PP films offer good moisture and oxygen barrier properties and are resistant to punctures and tears.

Polyester (PET) is a strong, high-clarity plastic film that is suitable for packaging products that require high barrier properties, such as coffee, snacks, and dried fruits. It is also suitable for packaging products that require microwaveable or oven-able pouches.

Plastic pouches are customizable, allowing businesses to showcase their brand with high-quality graphics and designs. However, plastic pouches are not biodegradable and can contribute to environmental pollution. They also have limited heat resistance and are not suitable for high-temperature applications.

Paper Pouches

Paper is a natural and biodegradable material that is becoming increasingly popular for pouch packaging. Paper pouches are lightweight, portable, and eco-friendly, making them an ideal option for dry food items such as nuts, seeds, and snacks.

Paper pouches are typically made from kraft paper, which is a sturdy and tear-resistant material. They are also customizable and can be printed with unique designs and graphics. However, paper pouches are not suitable for products that require high barrier properties, such as liquids and perishable food items.

Aluminum Foil Pouches

Aluminum foil is a high barrier material that is commonly used for packaging perishable food items, such as meat, dairy products, and beverages. Foil pouches offer excellent moisture and oxygen barrier properties, preventing spoilage and extending the shelf life of the product.

Aluminum foil pouches are puncture-resistant and tamper-evident, making them an ideal option for high-value products. They are also heat-sealable, ensuring the contents remain fresh and protected from external factors.

However, aluminum foil pouches are not suitable for microwave or oven-able applications. They are also not biodegradable and can contribute to environmental pollution.

Biodegradable Pouches

As consumers become more environmentally conscious, biodegradable pouches are becoming increasingly popular. These pouches are made from materials such as corn starch, sugarcane, and other natural fibers.

Biodegradable pouches break down quickly in the environment, leaving no harmful residues. They are also suitable for food items and offer similar barrier properties as traditional plastic pouches.

However, biodegradable pouches are more expensive than traditional plastic pouches and have limited availability. They may also have lower barrier properties than other materials, making them less suitable for certain products.

Composite Pouches

Composite pouches are made by combining different materials to create a customized packaging solution. For example, a composite pouch might combine plastic and aluminum foil to create a high barrier pouch suitable for packaging liquids and powders. Composite pouches offer a range of benefits, such as increased durability, enhanced barrier properties, and improved product shelf life.

Composite pouches are customizable and can be printed with high-quality graphics and designs. They are also tamper-evident, ensuring the contents remain fresh and protected from external factors.

However, composite pouches are more expensive than traditional plastic pouches and may not be suitable for all products. The use of multiple materials in composite pouches may also make them more difficult to recycle.

Summary: Which Pouch Material Should You Choose?

In conclusion, the choice of material used to make pouches depends on the product being packaged, the required barrier properties, and environmental considerations. From plastic and paper to aluminum foil and biodegradable materials, there are several options available for creating the perfect pouch for your product. By understanding the benefits and drawbacks of each material, businesses can make informed decisions about the best type of pouch packaging for their products.

If you are looking for custom pouches, then contact Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Exploring the World of Pouch Packaging Materials

A great packaging supplier can do more than just deliver boxes or pouches—they can become a valuable partner in your product’s success. When you build

Corrugated pads are an essential component of the packaging industry. They are versatile, durable, and cost-effective solutions for a wide range of packaging needs. Corrugated

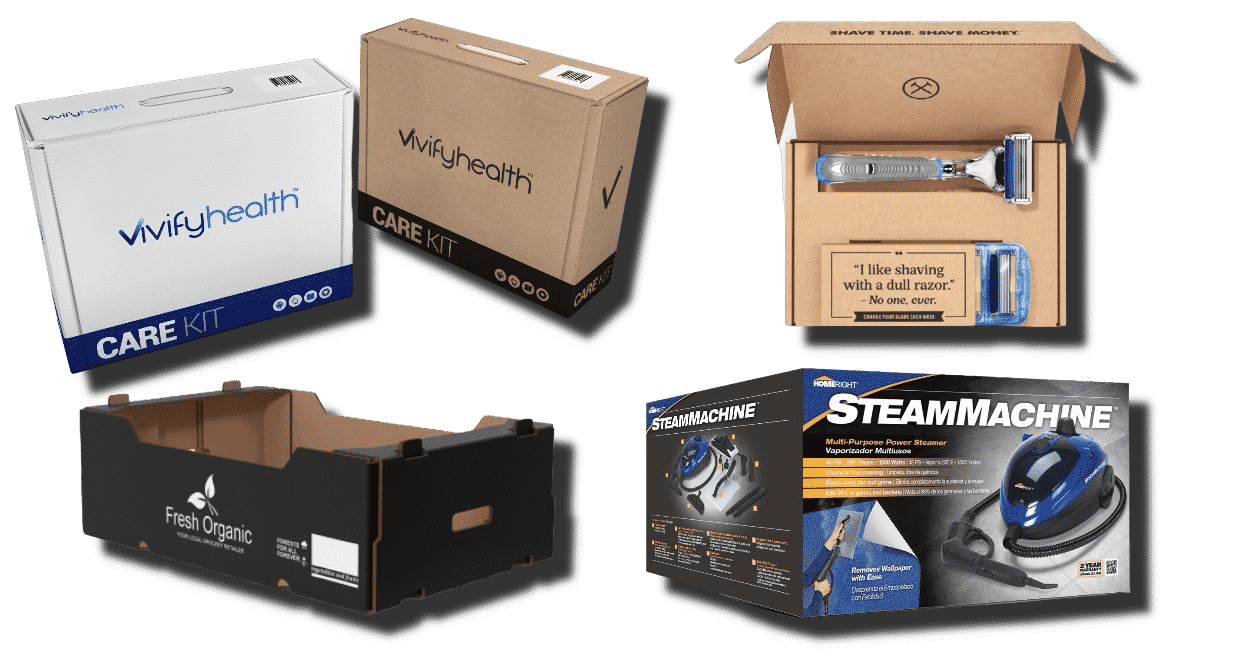

Corrugated boxes are highly effective for a wide range of packaging needs, providing superior protection, durability, and versatility. Their unique construction allows them to withstand