Home » Everything You Need to Know About Full Overlap Corrugated Boxes

Everything You Need to Know About Full Overlap Corrugated Boxes

Corrugated boxes are an essential part of the shipping and storage process for businesses worldwide. They are made of corrugated paperboard, which comprises three layers: an inside liner, an outside liner, and a corrugated medium. The fluted medium provides cushioning and strength to the box, while the liners provide a surface for printing and labels. There are several types of corrugated boxes, with full overlap (FOL) being one of the most popular due to its superior strength and durability.

What is Full Overlap (FOL) Corrugated Boxes?

Full overlap (FOL) corrugated boxes are designed with flaps that completely overlap, providing extra protection to the contents inside. The flaps on both the top and bottom of the box extend all the way to the opposite side of the box, ensuring maximum protection and support. The FOL design provides a stronger and more secure seal than other types of corrugated boxes, making it ideal for shipping and storage of heavy or fragile items.

Benefits of Full Overlap (FOL) Corrugated Boxes:

Durability and Strength

FOL corrugated boxes are known for their superior strength and durability, making them ideal for shipping and storing heavy and fragile items. The complete overlap of the flaps ensures that the box can withstand rough handling during transit without compromising the contents.

Protection

The complete overlap of the flaps provides an extra layer of protection to the contents inside the box, reducing the risk of damage during transit. The FOL design also prevents dust and dirt from entering the box, keeping the contents clean and protected.

Customizable

Full overlap corrugated boxes can be customized to fit the specific needs of the contents being shipped. The size and shape of the box can be tailored to fit the contents, and additional cushioning or inserts can be added to provide extra protection.

Cost-Effective

Despite their strength and durability, FOL corrugated boxes are cost-effective and affordable. They are also recyclable, making them an environmentally friendly choice for packaging.

Security

These corrugated boxes can be sealed tightly and securely with tape, ensuring that the contents remain inside the box during transit. The secure seal also helps prevent tampering and theft.

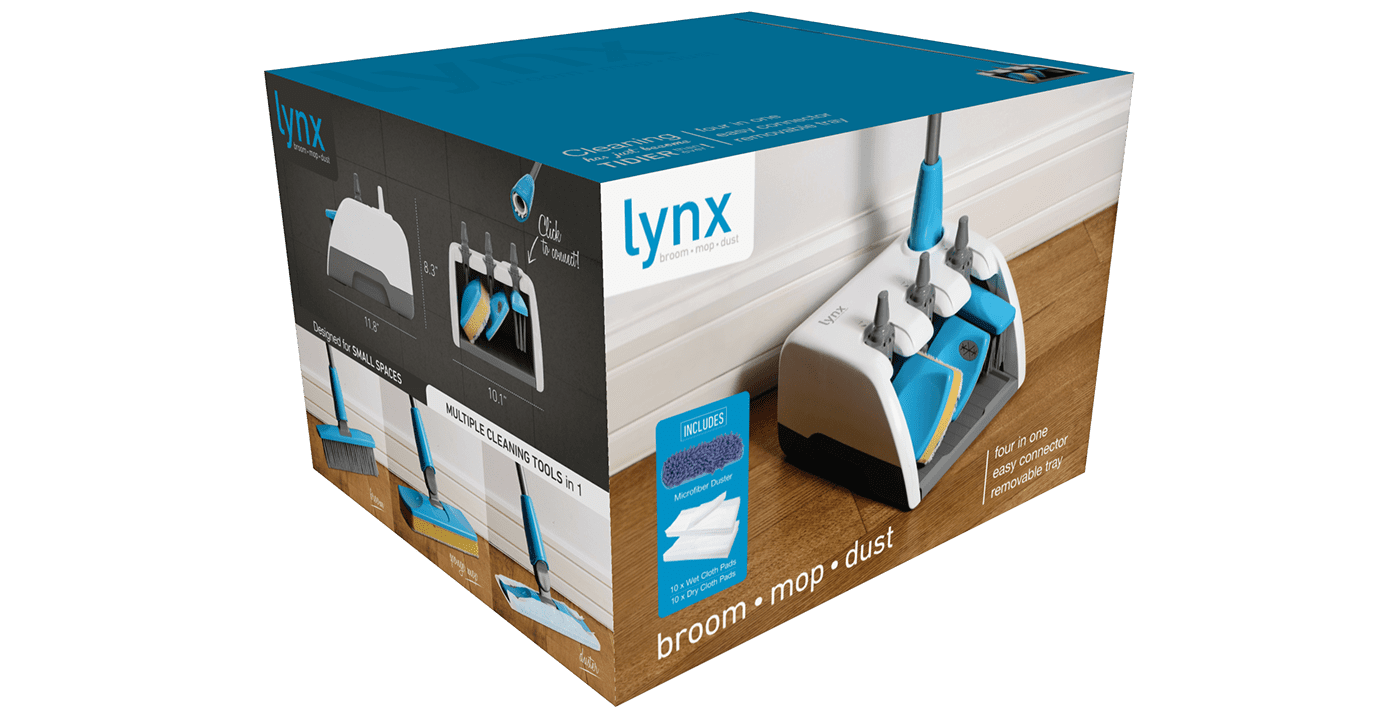

Branding

FOL boxes can be customized with a company logo or branding, providing an opportunity for businesses to promote their brand while also protecting their products.

Sustainability

Full overlap boxes are made from renewable materials and are recyclable, making them a sustainable packaging choice for businesses.

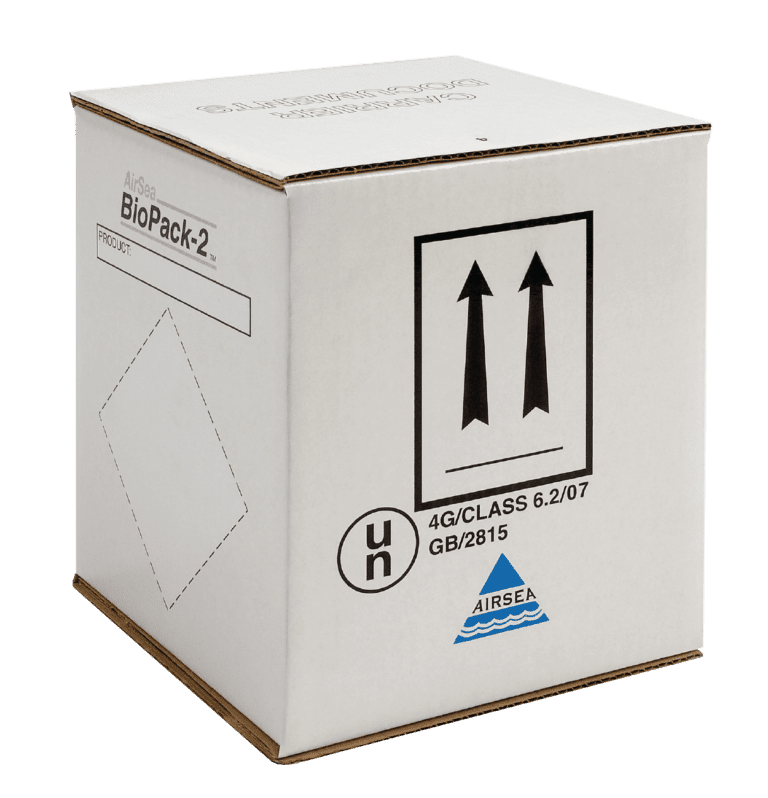

Compliance

Corrugated boxes can be designed to comply with various shipping regulations, ensuring that the contents arrive at their destination safely and securely.

Full Overlap Box Customization

FOL corrugated boxes can be customized to meet specific business needs. Customization options include:

Size and shape

The size and shape of the box can be tailored to fit the contents being shipped. Custom sizes and shapes can be created to ensure a perfect fit for the products.

Printing

FOL boxes can be printed with company logos, branding, and product information. This can enhance the customer experience and promote brand awareness.

Inserts and Cushioning

Additional inserts and cushioning can be added to FOL boxes to provide extra protection for fragile or delicate items.

Closure Options

FOL boxes can be customized with different closure options, including plastic or paper tape, Velcro, or staples.

When to Use Full Overlap (FOL) Corrugated Boxes:

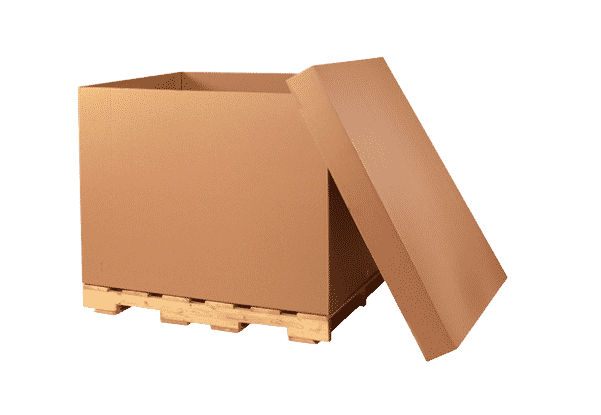

FOL corrugated boxes are ideal for shipping and storing heavy or fragile items that require extra protection. They are commonly used in industries such as manufacturing, automotive, and aerospace, where heavy and delicate components are shipped. FOL boxes are also commonly used for packaging equipment, machinery, and electronic devices. In addition, FOL boxes are ideal for shipping and storing items that require long-term storage, as they provide excellent protection against dust, dirt, and moisture.

FOL boxes can be used for a variety of products, including:

Industrial

Full overlap boxes are often used to ship and store large and heavy industrial equipment, such as generators, compressors, and pumps. The boxes can be customized to fit the specific dimensions of the equipment and can be reinforced with additional cushioning or inserts for added protection.

Automotive

Auto parts such as engines, transmissions, and axles are commonly shipped with full overlap boxes. The boxes can be customized to fit the specific dimensions of the parts and can be reinforced with additional cushioning or inserts for added protection.

Electronics

These boxes are ideal for shipping and storing electronic devices, such as computers, printers, and televisions. The boxes provide excellent protection against dust, dirt, and moisture, which can damage electronic components. FOL boxes can be customized with additional cushioning or inserts to provide extra protection for delicate electronic components.

Medical

FOL boxes are commonly used to transport medical supplies, such as surgical instruments, laboratory equipment, and diagnostic kits. The boxes can be customized to fit the specific needs of the contents and can be reinforced with additional cushioning or inserts for added protection.

Food and Beverage

Food and beverage products, such as canned goods and bottles are often packaged inside this type of box as it provides excellent protection against damage during transit and can be customized to fit the specific dimensions of the products.

Retail

These boxes can be used to package retail products, such as clothing, shoes, and accessories. The boxes can be customized with branding and logos to promote the brand and enhance the customer experience.

E-commerce

FOL boxes are commonly used for e-commerce shipments, as they provide a secure and durable packaging solution for products being shipped directly to consumers.

Summary: Full Overlap Boxes Explained

In summary, Full Overlap (FOL) corrugated boxes are an excellent choice for businesses that require a strong, durable, and protective packaging solution for their products. FOL boxes provide superior protection to heavy or fragile items during transit, and they can be customized to fit the specific needs of the contents being shipped.

Customization options include size and shape, printing, inserts and cushioning, and closure options. Whether shipping industrial equipment, automotive parts, electronics, medical supplies, food and beverage products, or retail and e-commerce products, FOL boxes provide a reliable and effective packaging solution. FOL boxes are also cost-effective, recyclable, sustainable, and compliant with shipping regulations, making them a popular choice for businesses in a variety of industries.

If you are interested in custom full overlap corrugated boxes, then partner with Brown Packaging today to get started.

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

Home » Everything You Need to Know About Full Overlap Corrugated Boxes

Packaging is not merely a practical aspect of shipping; it’s also a statement about your brand’s commitment to quality and protection. When it comes to

Gaylord containers are large, sturdy boxes used primarily for shipping, storing, and handling bulk materials. Often utilized in industries like manufacturing, agriculture, and retail, these

The longevity of corrugated boxes, a question frequently asked by businesses and consumers alike, hinges on several key factors, including their construction, material quality, and