Home » Digital Print in Packaging: A Comprehensive Guide

Digital Print in Packaging: A Comprehensive Guide

The packaging industry has undergone significant changes in recent years, with new technologies such as digital print revolutionizing the way packaging materials are produced. Digital print technology offers a cost-effective and efficient way to create customized packaging materials with unique designs and graphics, while minimizing setup time and cost.

In this comprehensive guide, we will explore what digital print is in packaging, how it works, its advantages and disadvantages, and its various applications. Whether you are a business owner looking to create customized packaging materials for your products or a consumer interested in the latest packaging trends, this guide provides valuable information on the benefits and limitations of digital print in packaging.

Overview: Digital Print Explained

This blog explores the topic of digital print in packaging, including what it is, how it works, its advantages and disadvantages, and its various applications. The guide will be explained:

What is Digital Print in Packaging?

Digital print in packaging is a printing process that uses digital technology to print high-quality graphics, images, and text directly onto packaging materials. Unlike traditional printing methods, which require expensive setup costs and long lead times, digital print technology enables businesses to create customized packaging materials quickly and cost-effectively.

Digital print technology works by using specialized software to create digital artwork or designs that are then printed directly onto the packaging material. The digital printer uses inkjet or laser technology to apply the design or image onto the surface of the material.

One of the key advantages of digital print technology is its ability to create customized designs, graphics, and text on a wide range of packaging materials, including paper, cardboard, plastic, and metal. This allows businesses to differentiate their products from the competition by creating unique packaging materials that stand out on store shelves.

Digital print technology also offers greater flexibility and speed than traditional printing methods. Because digital printers do not require the use of printing plates, setup time is significantly reduced, and changes to the design can be made quickly and easily. This makes digital print technology ideal for short runs and small batch orders, which can be produced in a matter of hours or days.

How Does Digital Printing in Packaging Work?

Digital print technology works by using specialized software to create digital artwork or designs that are then printed directly onto the packaging material. The process involves several steps: design creation, file preparation, printing and finishing.

Design Creation

The first step in the digital print process is to create the design or artwork that will be printed onto the packaging material. This is done using specialized software such as Adobe Illustrator, Photoshop or special programs created by the machine manufacturer. The design can include images, text, and graphics, and can be customized to meet the specific needs of the packaging project.

File Preparation

Once the design is complete, it is saved in a digital format that can be read by the digital printer. The file is then prepared for printing by adjusting settings such as color and resolution to ensure that the final print is of high quality.

Printing

The next step is to print the design onto the packaging material. The digital printer uses inkjet or laser technology to apply the design or image onto the surface of the material. The printer can print a single design or multiple designs on the same sheet, depending on the size and shape of the packaging material.

Finishing

Once the printing is complete, the packaging material is finished according to the desired specifications. This can include cutting, folding, and gluing to create the final packaging product.

Overall, digital print technology offers several advantages over traditional printing methods, such as offset printing. Unlike offset printing, which requires printing plates and complex setup processes, digital print technology does not require printing plates and has a much shorter setup time. This makes it ideal for short runs and small batch orders, which can be produced quickly and cost-effectively.

Additionally, digital print technology allows for greater flexibility in design, as changes can be made quickly and easily without incurring additional setup costs. This allows businesses to create customized packaging materials with unique designs and graphics, which can help them stand out from their competitors on store shelves.

Advantages of Digital Print in Packaging

Digital print technology offers several advantages over traditional printing methods, such as offset printing, for producing customized packaging materials. Some of the advantages of digital print in packaging are:

Customization

Digital print technology enables businesses to create customized packaging materials with unique designs, graphics, and text. This allows companies to differentiate their products from the competition and create packaging that aligns with their brand image and values.

Speed

Digital print technology has a fast turnaround time, allowing businesses to produce customized packaging materials quickly and efficiently. This is particularly useful for businesses with time-sensitive promotions or seasonal products.

Multi-SKU Printing

It is quite ideal for companies to print digitally for multiple SKU products. This is because digital printing is much more flexible and efficient than alternative printing methods in adjusting to changing art work.

Cost-Effective

Digital print technology eliminates the need for expensive setup costs associated with traditional printing methods. This allows businesses to produce short runs or small batch orders cost-effectively.

Sustainability

Digital print technology produces less waste than traditional printing methods, making it a more sustainable option for packaging materials. Additionally, digital printing uses water-based inks that are more environmentally friendly than solvent-based inks used in traditional printing methods.

High-Quality

Digital print technology produces high-quality images and text, providing businesses with a way to create packaging materials that showcase their products in the best possible light. The technology uses advanced color management systems that ensure accurate color reproduction and sharp image quality.

Flexibility

Digital print technology allows for greater flexibility in design, as changes can be made quickly and easily without incurring additional setup costs. This allows businesses to make design changes on the fly and produce customized packaging materials that meet their specific needs.

Disadvantages of Digital Print in Packaging

While digital print technology offers many advantages over traditional printing methods, it also has some disadvantages that should be considered when choosing packaging materials. Some of the disadvantages of digital print in packaging are:

Limited Material Compatibility

Digital print technology may not be compatible with all types of packaging materials, limiting the range of options available to businesses. Certain types of packaging materials, such as metal or glass, may not be suitable for digital printing, which could limit the range of design options available to businesses.

Higher Cost per Unit for Large Quantity Orders

While digital print technology eliminates the need for expensive setup costs, it may result in a higher cost per unit for larger quantity orders. This is because the cost of the ink and other consumables used in digital printing may be higher than traditional printing methods for larger print runs.

Limited Color Range

Digital print technology may have a limited color range compared to traditional printing methods, which may impact the final design of the packaging material. This can result in less accurate color reproduction and less vibrant colors compared to traditional printing methods.

Quality Limitations

Digital print technology may have some quality limitations, particularly when it comes to reproducing fine details and small text. This can result in the final packaging material having less sharpness and detail compared to traditional printing methods.

Durability

Digital print technology may not be as durable as traditional printing methods, particularly for materials that will be exposed to harsh environmental conditions, such as UV light or moisture. This can result in the design or image on the packaging material fading or deteriorating over time.

Digital Print Packaging Applications

Digital print technology is used in a wide range of packaging applications, including:

Product Packaging

Digital print technology is commonly used to create customized packaging materials for a variety of products such as food, cosmetics, and electronics. The technology allows businesses to create packaging that showcases their products and enhances their brand image.

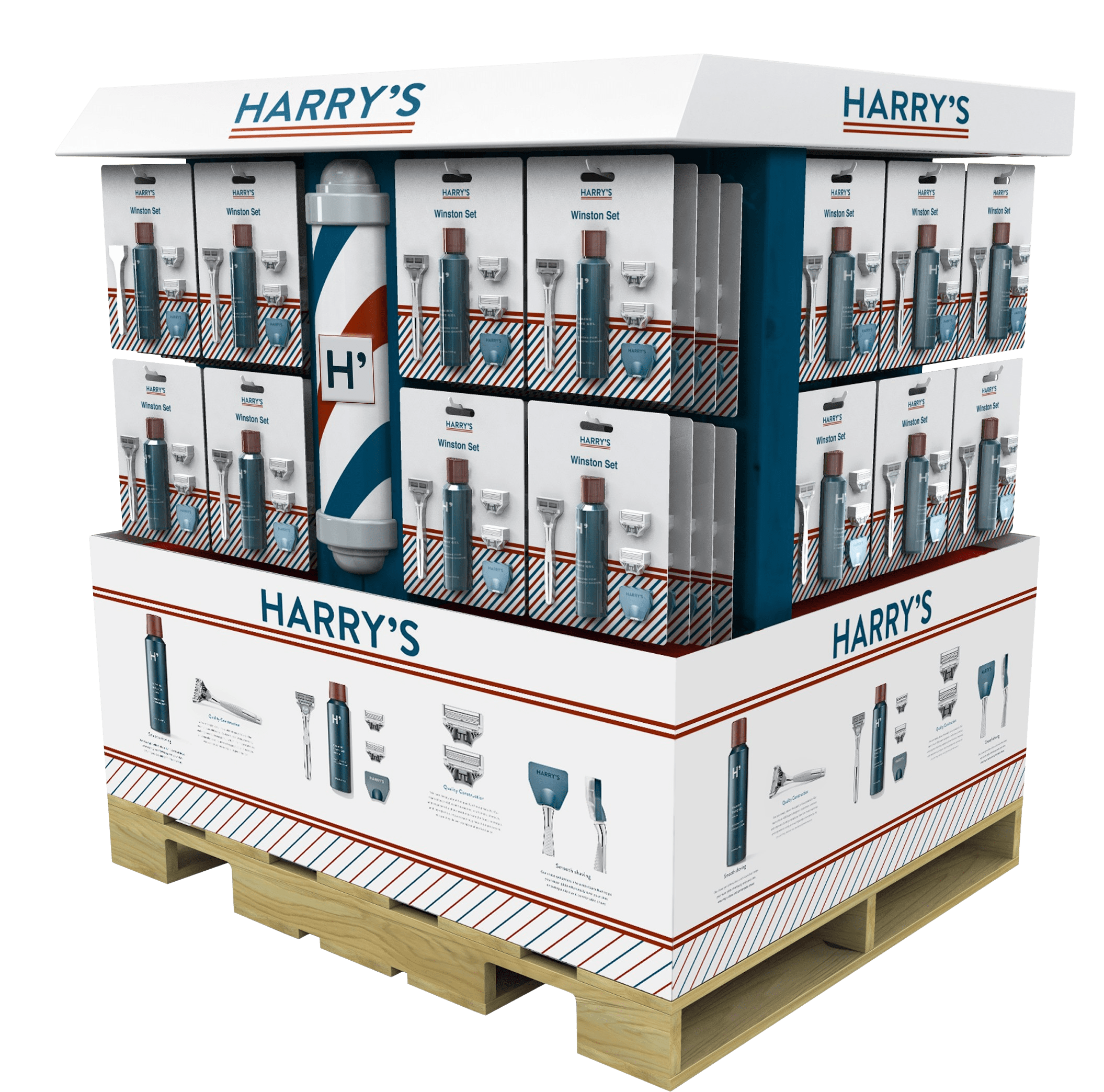

Promotional Packaging

Digital print technology is used to create promotional packaging materials such as gift boxes, seasonal packaging, and special edition packaging. These packaging materials often include customized graphics and text to promote a particular product or event.

Variable Data Printing

Digital print technology is used for variable data printing, which involves printing unique data such as serial numbers, barcodes, and variable text. This is particularly useful for products that require individualized packaging, such as pharmaceuticals or consumer electronics.

Prototyping

Digital print technology is used for prototyping, which involves creating a small run of packaging materials to test the design and functionality before mass production. This allows businesses to refine their packaging design and ensure that it meets the specific needs of their product and target market.

Short Runs

Digital print technology is particularly well-suited for short runs and small batch orders, which may be cost-prohibitive with traditional printing methods. This allows businesses to produce customized packaging materials quickly and cost-effectively, even for small product runs.

Personalized Packaging

Digital print technology is used to create personalized packaging materials, which allows businesses to create unique packaging for their customers. This can include custom text or images, which can help businesses to build brand loyalty and increase customer engagement.

Summary: Digital Print

In conclusion, digital print technology has transformed the packaging industry by providing businesses with a way to create high-quality packaging materials with customized designs and graphics, while minimizing setup time and cost. The technology offers several advantages over traditional printing methods, including greater flexibility, faster turnaround times, cost-effectiveness, and sustainability.

However, digital print technology also has some limitations and disadvantages, such as limited material compatibility, higher cost per unit for larger quantity orders, limited color range, quality limitations, and durability issues. These factors should be considered when choosing packaging materials and deciding whether digital print technology is the right choice for a particular project.

Despite these limitations, digital print technology has a wide range of applications in the packaging industry, including product packaging, promotional packaging, variable data printing, prototyping, short runs, and personalized packaging. Its versatility and cost-effectiveness make it an ideal choice for businesses looking to create customized packaging materials that align with their brand image and meet the specific needs of their products and target markets.

Overall, digital print technology is a valuable tool for businesses looking to enhance their packaging materials and stand out from their competitors. As the technology continues to evolve, it is likely that it will become an even more important part of the packaging industry in the future.

If you are interested in custom printed packaging, then partner with Brown Packaging today to get started.

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Home » Digital Print in Packaging: A Comprehensive Guide

When it comes to packaging, two critical elements come into play – structural design and graphic design. Both are essential in their ways, but depending

Why Board Grade Selection Matters In today’s volatile supply chain environment, packaging failures aren’t just a nuisance—they’re a liability. Damage in transit, product returns, and

Point of Purchase (POP) displays are a key element in influencing consumer decisions at the critical moment before purchase. The effectiveness of these displays can