Home » Custom Packaging Explained: Uses and Benefits

Custom Packaging Explained: Uses and Benefits

Custom packaging stands as a pivotal element for brands looking to differentiate their products in a crowded market. It is tailored specifically to meet the unique needs of a product while enhancing brand identity and consumer experience. Unlike standard packaging available to all, custom packaging is designed with specific graphics, sizes, shapes, and features unique to one brand, offering a myriad of benefits from protection to marketing.

What is Custom Packaging?

Custom packaging involves creating packaging solutions that are not only functional but also distinctively designed to reflect the brand’s identity and meet precise product specifications. This includes selecting appropriate materials, employing advanced printing techniques, and incorporating innovative structural designs to enhance both the aesthetic appeal and the protective capabilities of the packaging.

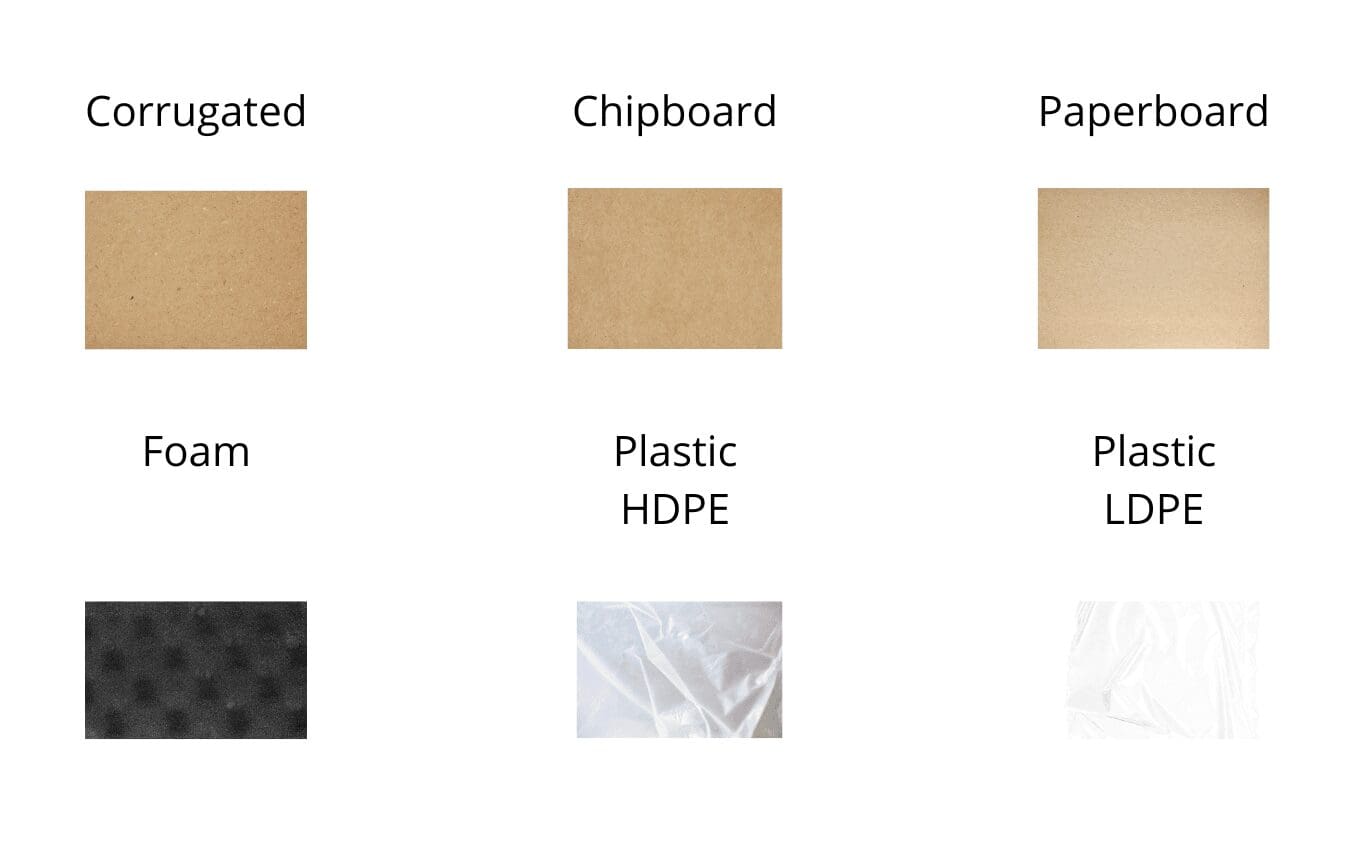

Popular Types of Custom Packaging

- Corrugated Boxes: Known for their strength and durability, used for shipping heavier items like electronics and appliances.

- Folding Cartons: These are cost-effective, lightweight, and ideal for packaging a wide range of consumer goods from food to pharmaceuticals.

- Pouches: Flexible and perfect for packaging small, lightweight items like snacks, powders, or liquids.

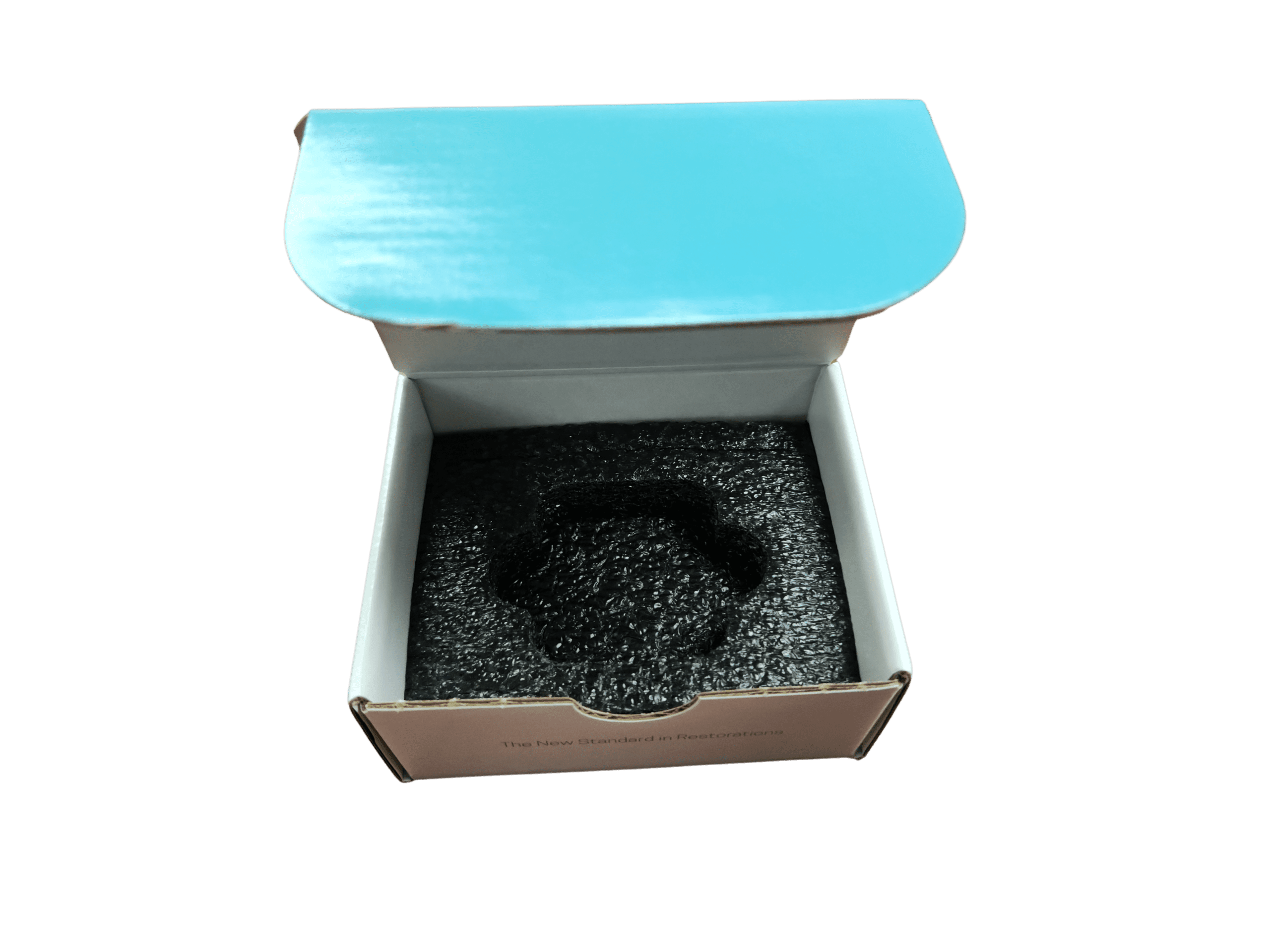

- Foam: Added to packages for cushioning and to keep products secure during transit.

- Blister Packs: Excellent for product visibility and security, commonly used for small consumer goods, electronics, and pharmaceuticals.

- Clamshells: Ideal for retail display, offering clear visibility and secure packaging for a variety of products.

- Poly Bags: Flexible bags used for lightweight, non-fragile items, often seen in retail settings.

Uses and Benefits of Custom Packaging

Enhanced Product Protection

One of the primary functions of custom packaging is to improve product protection. This is achieved through:

- Design: Tailoring the package’s size, shape, and materials to fit the product perfectly, minimizing movement and the potential for damage.

- Inserts and Dividers: These components are critical for keeping items in place and preventing contact that could lead to damage.

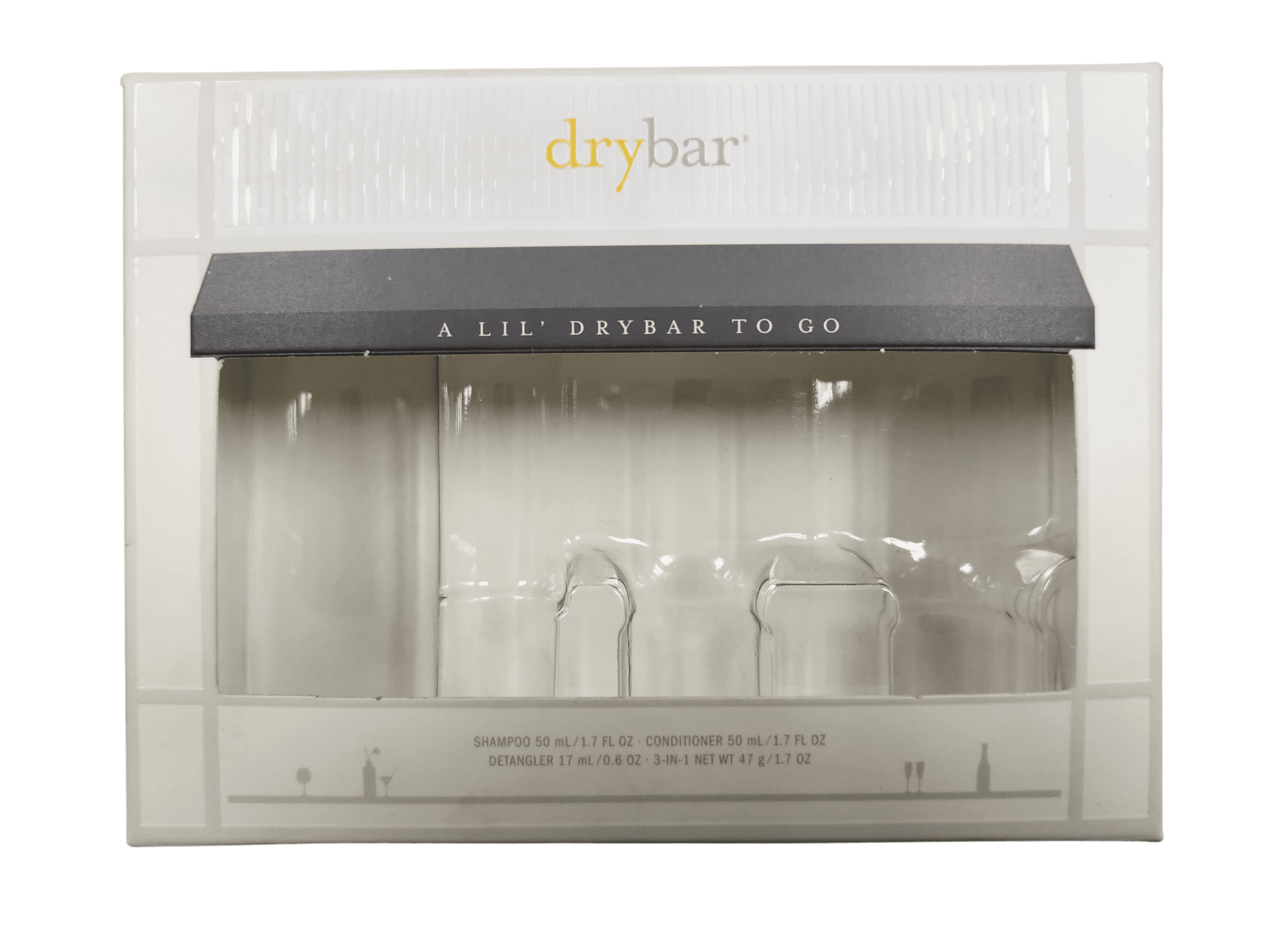

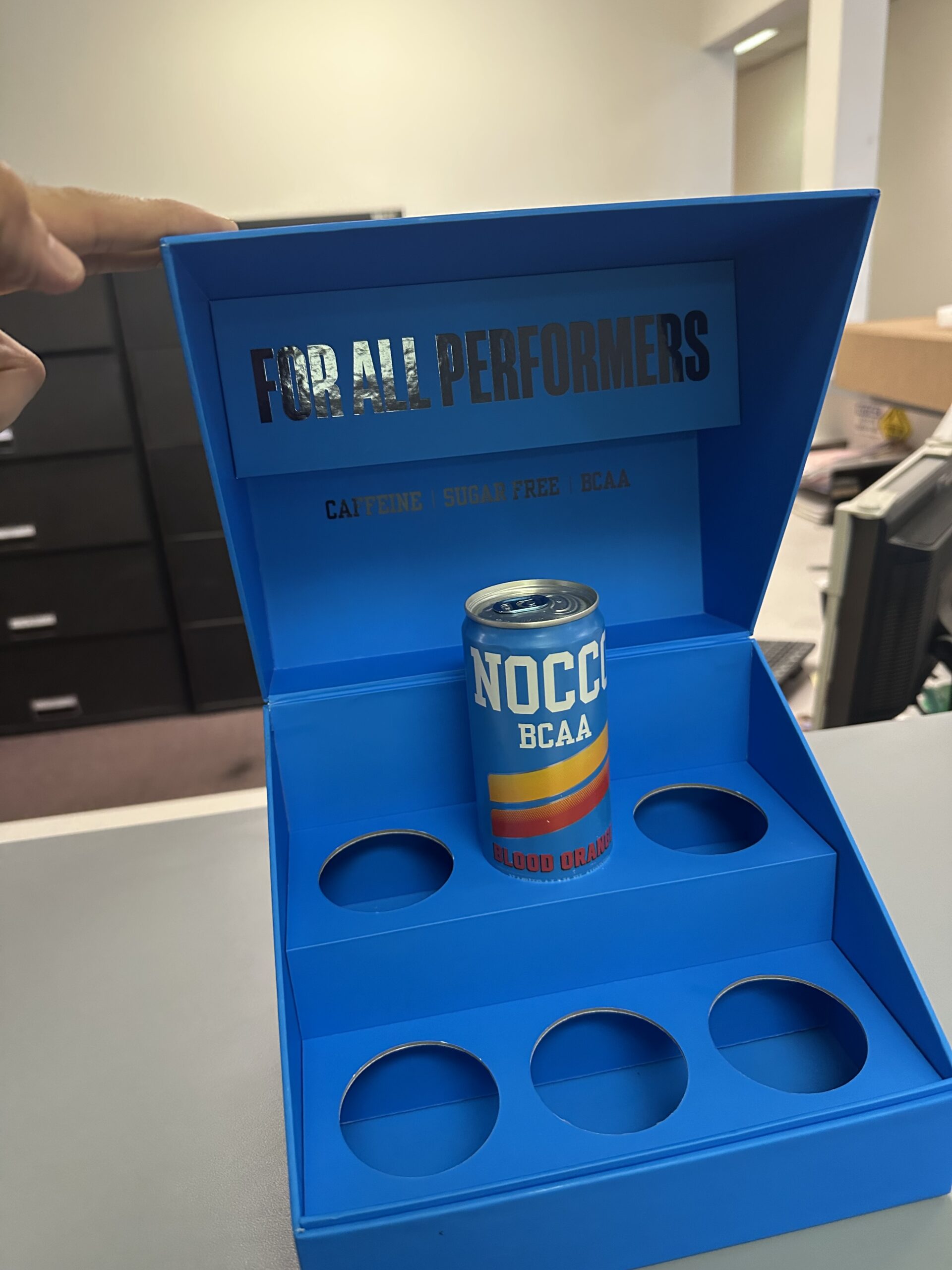

Branding and Market Differentiation

Custom packaging allows for complete control over the presentation of your product, which is vital for standing out on the shelf. It serves as a powerful marketing tool by incorporating:

- Graphics Design: This includes logos, brand colors, and other graphic elements that reinforce brand identity.

- Structural Design: Unique packaging shapes and structures can catch the eye of consumers, making the product more noticeable and appealing.

Corrugated Box and Folding Carton

Efficiency and Sustainability

Custom packaging can be designed to be both efficient and sustainable, helping brands align with environmental standards and reducing waste. It offers:

- Optimal Use of Materials: By using materials that are exactly required for the packaging, brands can minimize waste and reduce costs. Learn how to select the right packaging materials.

- Sustainable Options: There are opportunities to use materials that are recyclable, biodegradable, or sourced from sustainable practices.

Compliance and Safety

Ensuring that packaging complies with local, state, or federal regulations is crucial, particularly for products that require specific safety standards. Custom packaging can be tailored to meet these requirements, ensuring that products are not only safe to use but also compliant with regulatory standards.

Conclusion: The Strategic Advantage of Custom Packaging

Custom packaging is more than just a way to contain a product; it is a strategic tool that enhances product safety, boosts brand recognition, and supports marketing efforts. It allows businesses to convey their brand story, protect their products effectively during transit, and present their goods in the most appealing way possible. By investing in custom packaging, companies can improve customer satisfaction, enhance product visibility, and ultimately, drive sales.

For any brand looking to make a significant impact in the marketplace, custom packaging provides a compelling solution. It’s an investment that pays dividends in brand loyalty, customer satisfaction, and overall brand value. If you’re considering custom packaging for your products, partnering with a seasoned provider like Brown Packaging can ensure that your packaging needs are met with expertise and creativity.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Custom Packaging Explained: Uses and Benefits

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s