Home » Custom Packaging: Boost Your Brand Recognition and Customer Engagement

Custom Packaging: Boost Your Brand Recognition and Customer Engagement

Custom packaging has become a popular trend in recent years, as businesses seek to differentiate themselves and make a lasting impression on their customers. The packaging of a product plays a significant role in the customer’s experience and can have a major impact on their perception of the brand. By creating a unique and personalized packaging design, businesses can enhance brand recognition and customer engagement.

In this blog, we will explore the trend of custom packaging and how it can help businesses achieve their goals. From increased brand recognition to a more personalized customer experience, the benefits of custom packaging are numerous. We will also discuss the considerations that businesses need to keep in mind to ensure success with custom packaging, including factors such as the type of product being packaged, the target audience, and the brand identity.

So, whether you are a business looking to enhance your brand image or a customer searching for a more personalized shopping experience, this blog will provide valuable insights into the world of custom packaging. Read on to learn more about how custom packaging can benefit your business and enhance your brand recognition and customer engagement.

Increased Brand Recognition

Increased brand recognition is one of the primary benefits of custom packaging. A unique and recognizable packaging design can help to make a lasting impression on customers and increase brand awareness. When customers are exposed to a consistent and visually appealing packaging design, they are more likely to remember the brand and associate it with positive experiences. This helps to build brand loyalty and foster customer engagement, as customers are more likely to return to a brand, they are familiar with and trust.

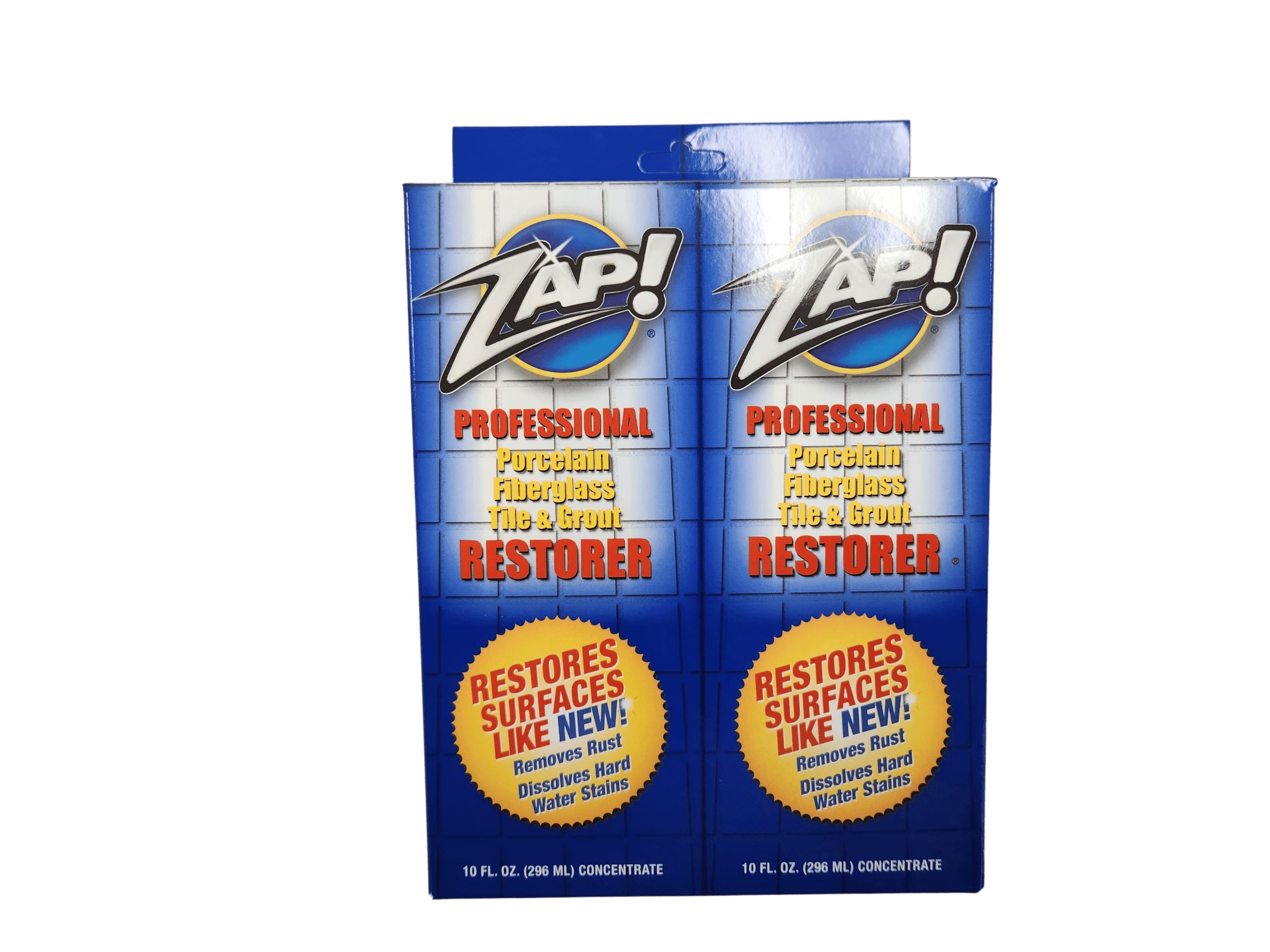

Incorporating elements such as custom branding, logos, and colors into the packaging design can also help to increase brand recognition. For example, a company could use its signature colors or logo on the packaging, making it easily recognizable and memorable to customers. This not only helps to build brand recognition but also serves as a marketing tool, as customers are more likely to notice and remember a distinctive packaging design.

In addition to visual elements, businesses can also use custom packaging to communicate the unique features and benefits of their products. By incorporating informative branding or product information into the packaging, businesses can differentiate themselves from their competitors and increase brand recognition.

Overall, custom packaging offers numerous benefits for businesses looking to increase brand recognition and foster customer engagement. By creating a unique and memorable packaging design, businesses can differentiate themselves from their competitors, build brand loyalty, and ultimately drive sales.

Personalized Customer Experience

Personalized customer experience is another key advantage of custom packaging. By incorporating elements such as personalized messaging, custom branding, and special packaging features, businesses can create a more meaningful and memorable customer experience. This not only helps to increase customer engagement but also fosters brand loyalty, as customers feel that their needs and preferences are being taken into consideration.

For example, a business could use custom packaging to create a special unboxing experience for its customers. This could include personalized messaging, such as a thank you note or a special message, that makes the customer feel valued and appreciated. The use of high-quality packaging materials, such as eco-friendly packaging or special packaging features, can also help to create a more personalized customer experience.

Personalized packaging can also be used to target specific customer segments. For example, a business could create special packaging designs for different age groups or customer interests. This not only helps to create a more personalized customer experience but also allows businesses to better understand and connect with their target audience.

In conclusion, personalized customer experience is a key advantage of custom packaging. By incorporating elements such as personalized messaging, custom branding, and special packaging features, businesses can create a more meaningful and memorable customer experience that increases customer engagement and fosters brand loyalty.

Marketing Tool

Custom packaging can serve as a powerful marketing tool for businesses, helping to increase brand recognition and drive sales. By creating a unique and visually appealing packaging design, businesses can differentiate themselves from their competitors and make a lasting impression on their customers.

One of the main benefits of custom packaging as a marketing tool is its ability to grab the attention of customers. A distinctive packaging design can help a product stand out on shelves, attracting the attention of customers and increasing the chances of a sale. This can be particularly important in crowded retail environments, where customers are faced with numerous choices and limited attention spans.

In addition to attracting attention, custom packaging can also serve as a platform for marketing messages and product information. By incorporating branding, logos, and product information into the packaging design, businesses can educate customers about their products and promote their brand. This not only helps to increase brand recognition but also drives sales by providing customers with the information they need to make an informed purchasing decision.

Custom packaging can also help businesses to create a consistent brand image across their product line. By using consistent branding, logos, and packaging designs, businesses can create a cohesive and recognizable brand image that helps to build brand loyalty and foster customer engagement.

Overall, custom packaging offers numerous benefits as a marketing tool, helping businesses to increase brand recognition, drive sales, and create a consistent brand image. Whether you are a small business looking to make a big impact or a large corporation seeking to stand out in a crowded retail environment, custom packaging can be a powerful marketing tool to help you achieve your goals.

Cost

Cost is an important consideration for businesses when it comes to custom packaging. While custom packaging offers numerous benefits in terms of increased brand recognition and customer engagement, it can also be more expensive than standard packaging options.

The cost of custom packaging can vary greatly depending on several factors, including the size and complexity of the packaging design, the type of materials used, and the quantity of packaging required. Businesses should also consider the costs associated with printing and production, as well as any additional costs associated with sourcing and shipping.

It is important for businesses to weigh the costs of custom packaging against the potential benefits, including increased brand recognition, customer engagement, and sales. In many cases, the additional investment in custom packaging can pay off in the long run, providing a strong return on investment through increased brand recognition, customer engagement, and sales.

Additionally, businesses can take steps to minimize the cost of custom packaging while still achieving their goals. For example, they can choose more cost-effective materials, such as recycled paper or biodegradable packaging, or opt for a more streamlined packaging design that reduces printing and production costs.

In conclusion, cost is an important consideration for businesses when it comes to custom packaging. While custom packaging can be more expensive than standard packaging options, the benefits in terms of increased brand recognition, customer engagement, and sales can often provide a strong return on investment. Businesses can take steps to minimize the cost of custom packaging while still achieving their goals, making it a cost-effective solution for many businesses looking to enhance their brand recognition and customer engagement.

Considerations For Success

To ensure success with custom packaging, there are several important considerations that businesses should keep in mind. These include:

- Understanding Your Target Audience: It is important to have a clear understanding of your target audience, including their needs, preferences, and buying habits. This information can help guide the design and messaging of your custom packaging, ensuring that it resonates with your target audience and drives sales.

- Creating a Distinctive Design: Your custom packaging should be visually appealing and distinctive, helping it to stand out on shelves and grab the attention of customers. The design should be reflective of your brand and consistent with your overall marketing strategy.

- Quality Materials: The quality of the materials used for your custom packaging is critical to its success. Not only should the materials be visually appealing and durable, but they should also be functional and provide the necessary protection for the products being packaged.

- Incorporating Branding and Messaging: Your custom packaging should prominently feature your branding and messaging, helping to increase brand recognition and drive sales. This includes the use of logos, slogans, and product information, as well as any personalized messaging.

- Cost Management: It is important to manage costs while creating custom packaging, ensuring that the benefits of the investment are maximized. This can include choosing cost-effective materials, reducing the complexity of the packaging design, and carefully managing production costs.

- Testing and Iteration: Finally, it is important to test and iterate on your custom packaging, ensuring that it is achieving its goals and providing the desired return on investment. This may involve making changes to the design, materials, or messaging, as well as ongoing testing and evaluation to ensure ongoing success.

In conclusion, success with custom packaging requires careful consideration and planning, including a clear understanding of your target audience, a distinctive and visually appealing design, high-quality materials, effective branding and messaging, cost management, and ongoing testing and iteration. By following these guidelines, businesses can ensure the success of their custom packaging, enhancing brand recognition and customer engagement, and driving sales.

Summary: Custom Packaging, Brand Recognition & Customer Engagement

In conclusion, custom packaging is a trend that is rapidly gaining popularity, and for good reason. By offering personalized experiences, businesses can enhance brand recognition and customer engagement, driving sales and providing a strong return on investment. Whether you’re a small business looking to differentiate yourself from the competition or a large corporation looking to strengthen your brand, custom packaging can provide a range of benefits.

However, it is important to keep in mind the various considerations for success, including understanding your target audience, creating a distinctive design, using quality materials, incorporating branding and messaging, managing costs, and testing and iterating to ensure ongoing success. With these guidelines in mind, businesses can create effective custom packaging that meets their goals and enhances their brand recognition and customer engagement.

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

Home » Custom Packaging: Boost Your Brand Recognition and Customer Engagement

In the world of logistics and supply chain management, the cost of shipping plays a pivotal role in determining a company’s profitability. While factors like

In a supply chain, your packaging is subjected to various stresses, including being pushed, pulled, dropped, and compressed against other packages. Proper packaging techniques are

Retail point of purchase (POP) displays are essential tools for marketing products directly to consumers within retail environments. These displays vary widely in shape, size,