Home » Corrugated Product Manufacturing Methods

Corrugated Product Manufacturing Methods

When you see packaging, you don’t see the process it went through, you just see the result. It is important to understand how each package is created, especially if you are looking for packaging for your business.

The two most common manufacturing processes include flexo folder gluer and die cutting. Flexo folder gluer is best used for certain style boxes, mainly used for shipping. While die cut is best used for custom boxes, such as mailers and inserts. One of the main differences between these methods is the requirement for tooling. Flexo folder gluer can operate without a tool, whereas die cut products will require specific tooling depending on the style of the box.

To make the best choice for your business needs, you must understand the differences between the machines.

Machine Run:

What is flexo folder gluer?

The flexo folder gluer is a machine that produces boxes with a wide range of configurations available to suit any production level. It can produce boxes without requiring a tool. This system prints, scores and slots the boxes before folding and gluing them together. Although this machine is full-service, it can only make certain styles of boxes.

Styles that can be made with this machine:

RSC- Regular slotted container

HSC- Half slotted container

FOL- Full overlap

POL- Partial overlap

The main elements of flexo folder gluer:

- Feeder: stacks and squares the boards before moving into the machine at the required speed

- Flexographic print units: one for each color

- Creasing and slotting units: cut and score the boards, to create flaps and panels

- Folder gluer: apply adhesive to the glue tab and fold

- Counter ejector: stacks the boxes in the required quantities according to the thickness of the material.

Die Cut:

What is die cutting?

Die cutting is a process that transforms material by cutting, forming, and shearing it into custom shapes and designs. This machine requires tools and uses rollers and cutting plates to put pressure on a die to push through and create a precise die cut. If you are ordering specific style boxes, then you will need to use a die cut machine. There is two important kinds of die cutting; flatbed and rotary.

Flatbed die cutting-

Flatbed die cutting cuts the desired shape out of material using a hydraulic flatbed press. This works well for low volume projects of consistent cut or larger sized products.

Advantages:

- Lower tooling cost

- Max tonnage pressures

- Process thicker materials in larger and wider sizes

Disadvantages:

- Slower

- Price per piece is more expensive

Rotary die cutting-

Rotary die cutting uses a cylindrical die to cut shapes out of material. These cylinders are fully covered in blades to cut out the desired shape as it moves around in a circular motion. This machine cuts a wide range of designs with the highest degree of precision and accuracy.

Advantages:

- Consistent cutting speeds and precision

- Faster production

- High volume productions

Disadvantages:

- Tooling is more expensive

- Stricter size constraints

Summary Machine Run vs Die Cut:

Selecting between machine run and die cut just comes down to what kind of packaging your business needs. The main determining factor between choosing machine run or die cut depends on the style and if a tool is required to cut the boxes. If it is a specific style or shaped box and a tool is needed to cut the boxes, then die cut would be the best option. If no tools are required, then machine run would be the best option. Machine run only makes certain style of boxes which are mainly used for shipping purposes, if any other style is needed then you must use a die cut machine.

Each process has its advantages and disadvantages, it is just important to decide which will work best for your business packaging needs. If unsure of which process is needed for your business, contact Brown Packaging today to speak with one of our packaging specialists.

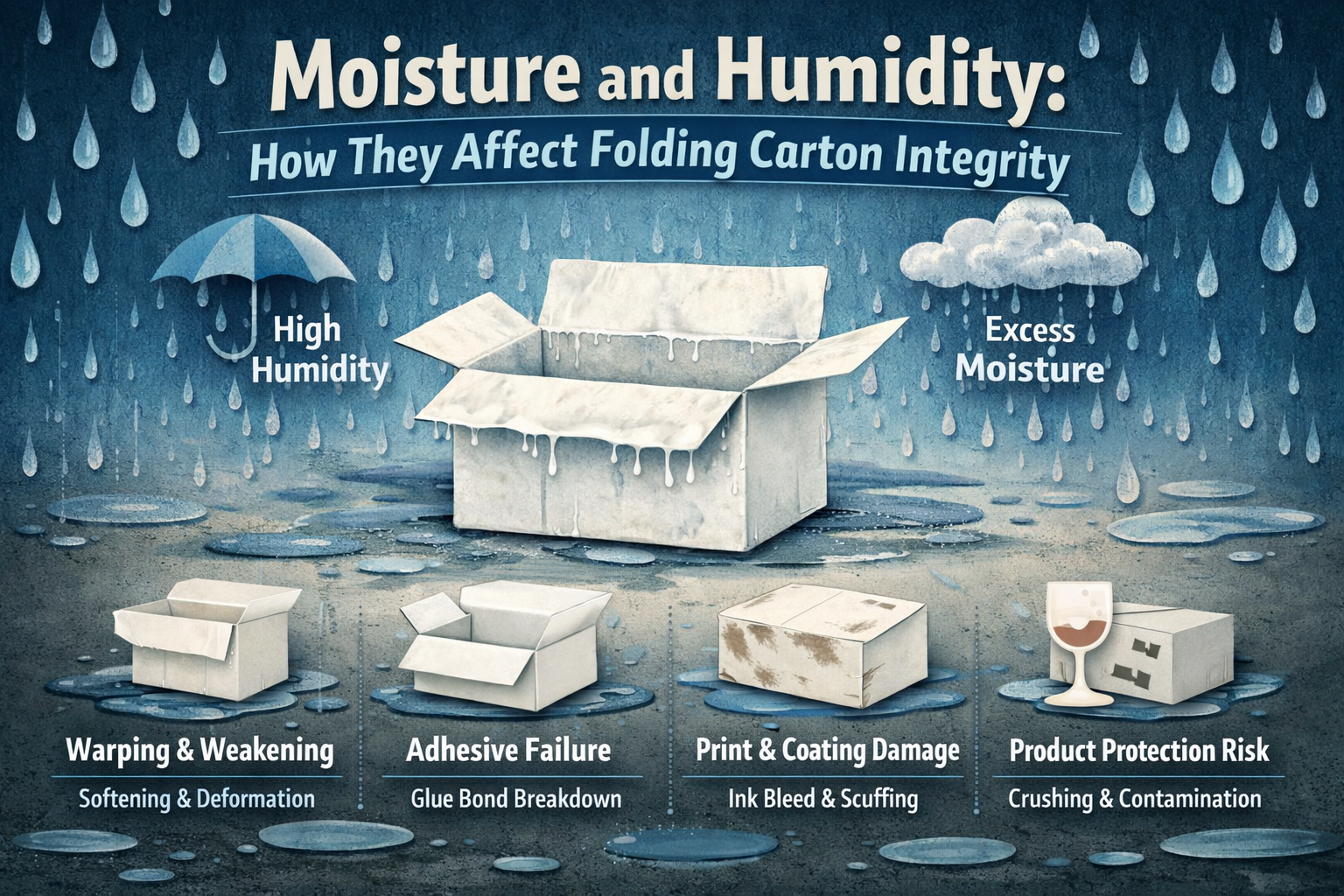

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Corrugated Product Manufacturing Methods

Unboxing has become a core part of the e-commerce experience, especially during the holidays. Seasonal packaging creates anticipation, reinforces branding, and turns customer deliveries into

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

The cold chain is a temperature-controlled supply chain that plays a critical role in ensuring that certain products, such as pharmaceuticals, vaccines, and food, maintain