Home » Contract Packaging: Everything You Need to Know

Contract Packaging: Everything You Need to Know

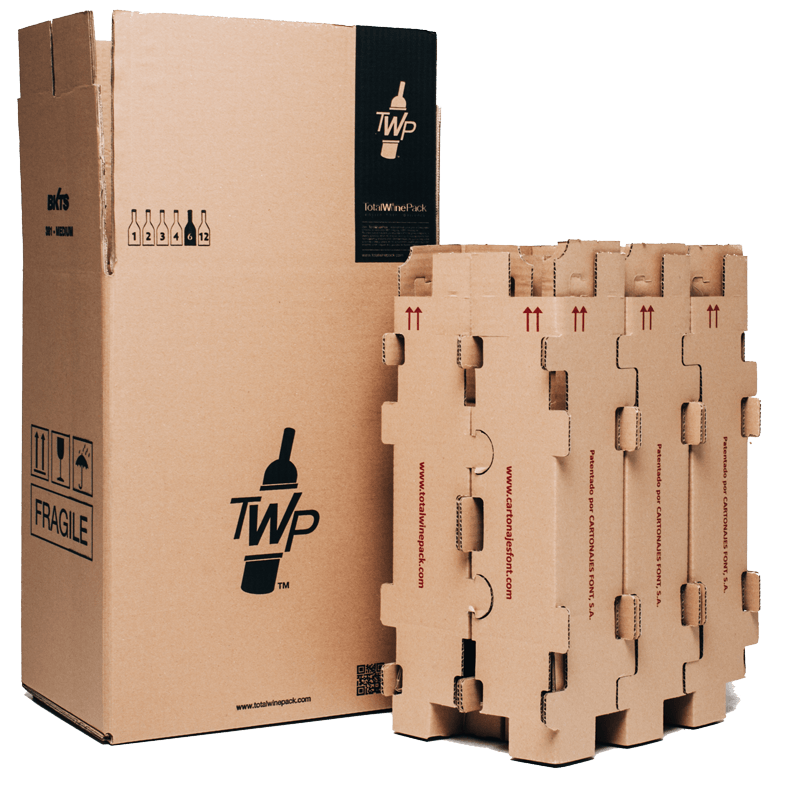

Contract packaging, also known as co-packing or third-party packaging, is a service where a company outsources the packaging of their products to a specialized provider. This provider, known as a contract packager, offers a wide range of packaging services, including assembly, filling, sealing, labeling, and packaging design.

Who Needs Contract Packaging?

Companies that need contract packaging services typically fall into one of several categories:

Manufacturers

Manufacturers of consumer goods, such as food, beverage, personal care, and household products, may outsource their packaging to a contract packager to increase efficiency and reduce costs. For example, a beverage manufacturer may outsource the bottling and labeling of their products to a contract packager.

Retailers

Retailers may use contract packaging services to package and distribute their own private label products, or to package and distribute products for other brands. For example, a retail chain may outsource the packaging of their own brand of cereal to a contract packager.

Pharmaceuticals and Medical Device Companies

These companies may outsource their packaging to a contract packager to ensure compliance with strict regulations and to meet the specific packaging needs of their products. For example, a pharmaceutical company may outsource the packaging of their tablets to a contract packager that specializes in child-resistant packaging.

Small Businesses

Small businesses may not have the resources or expertise to handle their own packaging and may choose to outsource to a contract packager to save time and money. For example, a small business owner may outsource the packaging of their handmade candles to a contract packager.

Start-ups

Start-ups may also outsource packaging to a contract packager to get their products to market quickly while they focus on growing their business. For example, a start-up company may outsource the packaging of their new line of skincare products to a contract packager.

E-commerce Companies

E-commerce companies may use contract packaging services to fulfill orders, package products for shipping, and handle returns. For example, an e-commerce company may outsource the packaging and shipping of their apparel products to a contract packager.

Logistics Companies

Logistics companies may outsource packaging services to a contract packager to handle packaging and shipping needs for their clients. For example, a logistics company may outsource the packaging of their clients’ products to a contract packager.

Benefits and Disadvantages of Contract Packaging

The Benefits of Contract Packaging

- Cost savings: By outsourcing packaging to a contract packager, companies can reduce their labor and equipment costs.

- Increased efficiency: Contract packagers often have the latest equipment and technology to handle a wide range of packaging needs, which can increase efficiency and speed up the packaging process.

- Flexibility: Companies can choose to outsource only certain aspects of their packaging process, such as assembly or filling, rather than handling the entire process in-house.

- Compliance: Contract packagers often have expertise in specific areas, such as child-resistant packaging or food packaging, which can help ensure compliance with regulations.

- Scalability: Companies can scale up or down their packaging needs depending on demand.

The Disadvantages of Contract Packaging

- Loss of control: Outsourcing packaging to a contract packager means giving up some control over the packaging process.

- Quality control: It can be difficult to ensure the same level of quality control as when packaging in-house.

- Communication: It can be difficult to ensure clear communication between the company and the contract packager, which can lead to mistakes or delays.

- Dependence: Companies may become dependent on the contract packager, which can be problematic

If you are interested in contract packaging or packaging products for your company, then reach out to Brown Packaging today to get started.

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

Home » Contract Packaging: Everything You Need to Know

In the world of packaging, there’s a constant pursuit of innovation and improvement to ensure products are not only securely packaged but also easy to

In recent years, the world has seen a rapid growth in the e-commerce industry. With the convenience of online shopping and the ability to purchase

When choosing corrugated board for packaging, print quality is often a critical consideration. Two common board types—ECT (Edge Crush Test) board and Bursting Test board,