How to Handle Packaging Price Increases

Packaging prices don’t always stay still. Whether due to raw material costs,

Packaging prices don’t always stay still. Whether due to raw material costs,

Packaging isn’t just a box or a bag—it’s a line item on

Before a customer ever opens your product, they’ve already formed an opinion—based

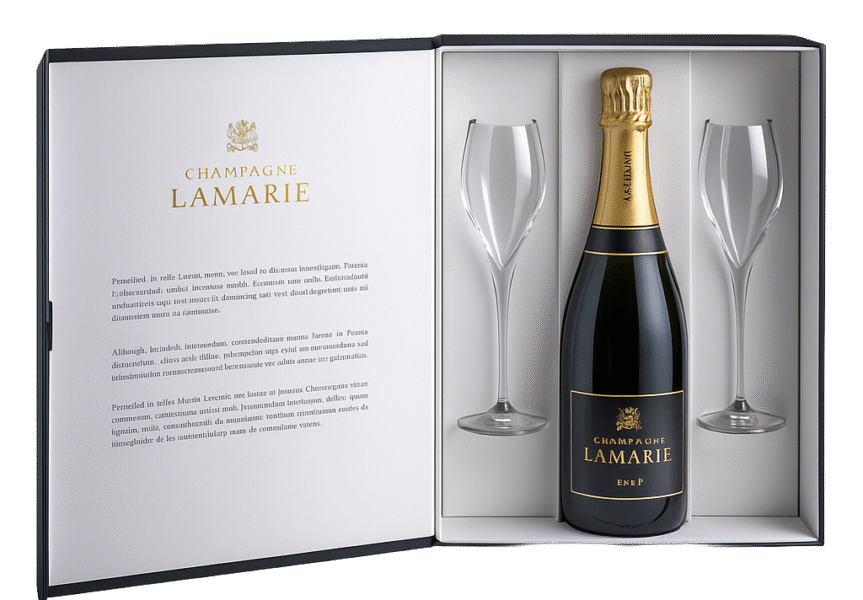

High-end products deserve more than protection—they require packaging that conveys value, craftsmanship,

Not every product calls for ultra-premium packaging—but that doesn’t mean you have

For pharmaceutical companies, sourcing packaging has become more complex in recent years.

Your packaging budget isn’t just about cost—it’s about timing, opportunity, and alignment

Evolving Demands, Smarter Decisions As 2026 approaches, packaging decision-makers across sectors—from retail

Why Holiday Fulfillment Demands Precision The holiday season introduces a unique set

Why Co-Packaging Becomes Critical During the Holidays As the holiday season approaches,

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

After the holiday rush, many packaging buyers face inflated costs from excess materials, rushed procurement, and seasonal surcharges. Q1 is the ideal time to reset,

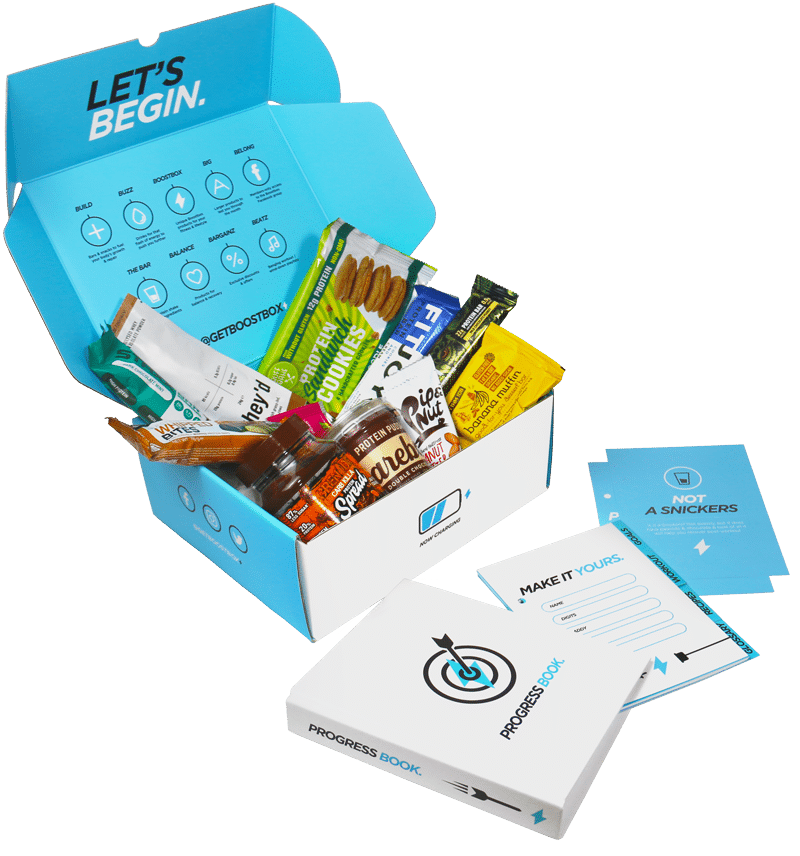

Subscription packaging remains one of the fastest-growing segments in e-commerce. In 2026, buyers face rising consumer expectations, stricter sustainability standards, and the need for efficient

Affordability used to be a quiet compromise — a goal that lived behind the scenes while marketing focused on gloss and finish. But in today’s

The Challenge Parakeet Cafe was preparing a holiday coffee blend promotion and needed custom digital printed pouches that reflected a festive, premium look. While the

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are