Home » An Advanced Guide to Corrugated Boxes

An Advanced Guide to Corrugated Boxes

Corrugated boxes are more than mere containers; they’re the culmination of engineering, design, and environmental consideration. This advanced guide delves into the nuances of corrugated boxes, offering in-depth knowledge for those looking to master their use in packaging.

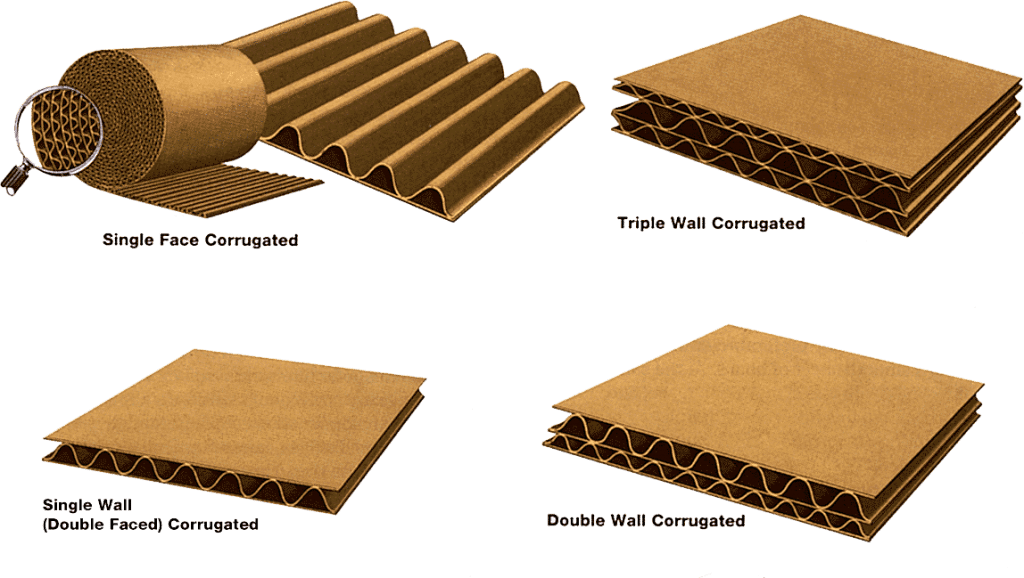

The Complex Anatomy of Corrugated Boxes

Understanding the structure of corrugated boxes is crucial for maximizing their utility.

- Flute Profiles Explained: Each flute type – A, B, C, E, and F – has specific characteristics. A-flute offers excellent cushioning, B-flute is great for die-cutting and printing, C-flute strikes a balance between cushioning and stacking strength, E-flute offers superior printability, and F-flute is ideal for retail packaging.

- Wall Construction Varieties: The choice between single, double, or triple wall construction impacts the box’s strength and durability. Each type serves different shipping and handling requirements.

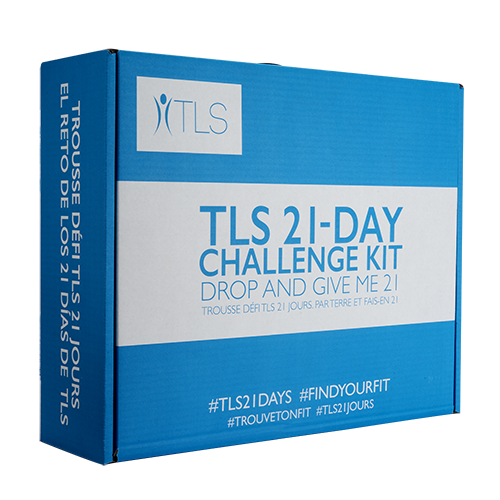

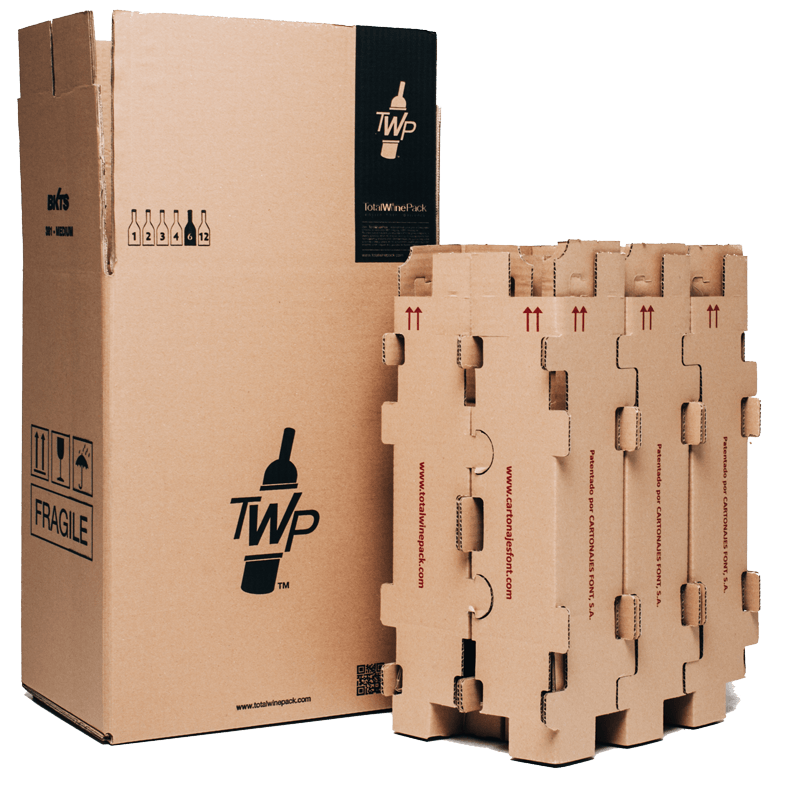

Diverse Types of Corrugated Boxes

Selecting the right box type is critical for product protection and cost efficiency.

- Regular Slotted Containers (RSC): The industry standard, versatile for a wide range of products.

- Full Overlap Boxes (FOL): Their overlapping flaps provide added strength for heavy or delicate items.

- Die-Cut Boxes: Custom-made for unique product shapes, offering both functionality and aesthetic appeal.

- Mailer Boxes: Popular in e-commerce, they provide a secure and presentable packaging solution.

Customization and Branding Techniques

Corrugated boxes are a blank canvas for branding and customization.

- Advanced Printing Methods: Flexographic, lithographic, and digital printing offer varied benefits from cost efficiency to high-resolution graphics.

- Structural Customization: Designing inserts, partitions, and dividers for product-specific protection and presentation.

- Surface Treatments: Laminations, coatings, and varnishes not only protect the product but also enhance the tactile and visual appeal of the box.

Measuring Strength and Durability

The resilience of a corrugated box is key to its performance.

- Understanding ECT vs. Mullen Test: The Edge Crush Test (ECT) measures stacking strength, while the Mullen Test assesses bursting strength. The choice depends on the product’s shipping and storage needs.

- Quality Standards and Certifications: Familiarize with industry standards like the Box Maker’s Certificate (BMC), which guarantees certain strength parameters.

Sustainability in Focus

Corrugated boxes play a significant role in sustainable packaging.

- Environmental Impact of Materials: Emphasize the use of recycled content and the recyclability of the boxes.

- Lifecycle Assessment: Consider the environmental impact throughout the box’s lifecycle, from production to disposal.

- Sourcing Ethics: Ensure the raw materials are sourced following sustainable forestry practices.

Leveraging Technological Innovations

Stay abreast of technological advancements that enhance corrugated box utility.

- Smart Packaging Features: Integrate technologies like QR codes, RFID tags, and IoT devices for tracking, user engagement, and authenticity verification.

- Automated Production Techniques: Understand the latest in box manufacturing technology for improved precision and efficiency.

Regulatory Compliance and Industry Standards

Navigating the maze of regulations is vital for hassle-free distribution.

- Shipping and Handling Compliance: Ensure your boxes meet the carrier’s requirements for size, weight, and strength.

- Adhering to Industry-Specific Norms: Certain sectors like food, pharmaceuticals, and electronics have specific packaging standards that must be followed.

If you are interested in custom or stock corrugated boxes, then partner with Brown Packaging today to get started.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » An Advanced Guide to Corrugated Boxes

When choosing corrugated board for packaging, print quality is often a critical consideration. Two common board types—ECT (Edge Crush Test) board and Bursting Test board,

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

In the world of packaging, the visual appeal of your product plays a significant role in catching the customer’s eye and leaving a lasting impression.