Home » Heat Seal Vs Cold Seal Packaging: Which Should You Choose?

Heat Seal Vs Cold Seal Packaging: Which Should You Choose?

Choosing the right sealing method impacts product quality, cost, durability, and speed to market. The two most common options—heat seal and cold seal—each have distinct strengths and limitations. By understanding how these methods differ, buyers can select the most effective solution for food, medical, industrial, and consumer products.

What is Heat Seal?

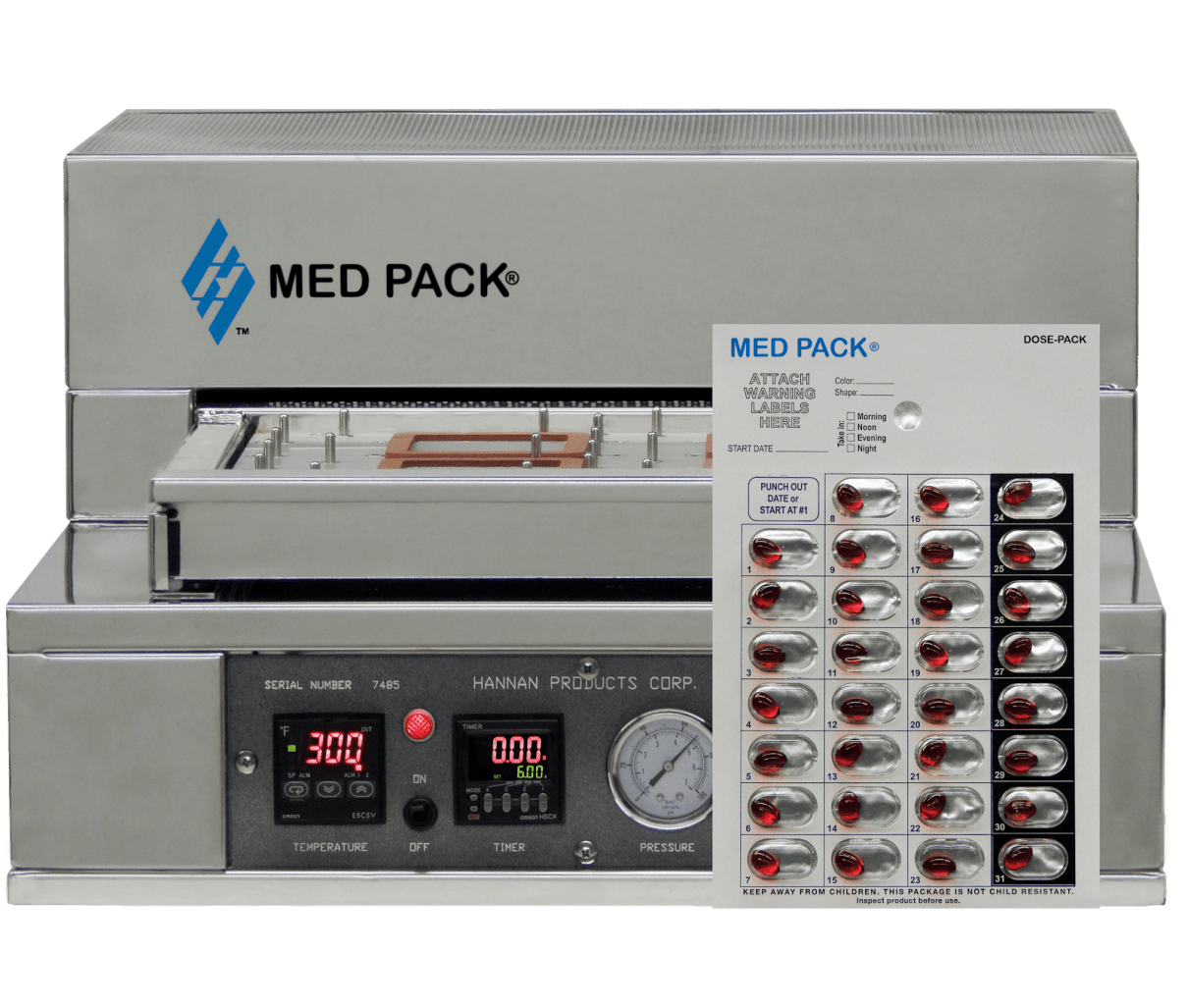

Heat seal packaging uses heated surfaces to melt the sides of a film or a sealant coating together. This creates a tight, durable closure that resists outside elements. Because it supports multi-layered films with barrier properties, heat seal remains one of the most widely used sealing methods.

Applications

Heat seal is often used for snacks, dry goods, frozen foods, and pasta. In addition, medical devices, electronic components, and industrial items such as screws or fittings are frequently packaged this way. These products are typically sealed in pouches, sachets, plastic bags, or blister packs.

Advantages

Provides strong seals resistant to chemicals, moisture, and harsh environments.

Creates a tamper-evident closure.

Works without adhesives.

Disadvantages

However, high temperatures can damage products such as chocolate or ice cream.

Production requires precise monitoring of time, temperature, and pressure.

Sealing speed is up to 10 times slower than cold seal.

Heated machinery increases the risk of burns and workplace injuries.

What is Cold Seal?

Cold seal packaging bonds film surfaces by applying a cohesive coating that sticks only to itself when pressure is added. Since heat is not required, this process is faster and well suited for products sensitive to high temperatures.

Applications

Cold seal is common for chocolates, ice cream, pharmaceuticals, baked goods, flammable items, and other temperature-sensitive products. Packaging formats include pouches, roll stock, chipboard cartons, clamshells, and blister packs.

Advantages

Much faster than heat seal because no warm-up is needed.

Protects heat-sensitive products.

Easier to open, enhancing consumer convenience.

Disadvantages

However, seal strength is lower than heat seal.

Requires cohesive material, adding cost.

Not chemical resistant, limiting use in some food and beverage applications.

Which Method Should You Choose?

Heat seal provides maximum strength, durability, and tamper resistance, making it ideal for applications that demand barrier protection. In contrast, cold seal offers higher production speed and protects heat-sensitive products, though with reduced strength. Ultimately, the choice depends on your product type, performance requirements, and fulfillment environment.

Sealing Solutions with Brown Packaging

Whether you need the superior durability of heat seal or the speed and temperature protection of cold seal, Brown Packaging delivers customized solutions to match your application. Contact us today to get started.

References

Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.

FDA. (2023). Food Contact Substances and Packaging Materials Guidance. U.S. Food and Drug Administration.

Fibre Box Association. (2022). Sealing and Packaging Methods Overview. Retrieved from https://www.fibrebox.org

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss,

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In

Home » Heat Seal Vs Cold Seal Packaging: Which Should You Choose?

Temperature fluctuations can have a detrimental effect on your products and packaging. Whether your goods are sensitive to extreme heat or cold, maintaining the right

When designing flexible packaging for perishables, customers often have initial ideas for graphics but lack clarity on functional aspects critical to product performance. Shelf life

Corrugated packaging is a popular packaging option for a wide range of products due to its strength, durability, and cost-effectiveness. In 2023, several trends are