Home » Anti-Static Packaging and Electrostatic Discharge Explained

Anti-Static Packaging and Electrostatic Discharge Explained

What Is Anti-Static Packaging?

Anti-static packaging is designed to control static discharge and protect sensitive electronics from electrostatic effects that can cause product failure or even ignition in flammable environments. Many businesses experience product loss, operational disruptions, and costly replacements due to improper packaging that fails to prevent electrostatic discharge (ESD).

This type of packaging is made with specialized anti-static materials and additives that dissipate static buildup, ensuring electronics remain safe during storage, handling, and transit. Available in various forms—including poly bags, bubble wrap, foam inserts, and stretch film—anti-static packaging is a critical investment for businesses dealing with sensitive electronic components.

Understanding Electrostatic Discharge (ESD)

Electrostatic discharge (ESD) is the sudden transfer of static electricity between two objects, which can damage electronic circuits and ignite flammable materials. Studies estimate that between 8% to 33% of damaged electronics suffer from ESD-related failures, costing the electronics industry billions annually.

Common sources of ESD include:

- Human Contact: A person’s body naturally generates and transfers electrostatic charges when touching sensitive components.

- Equipment & Machinery: Automated systems, conveyor belts, and trolleys generate static electricity during operation.

- Charged Insulators: Materials like plastic and polyethylene retain charges that can damage electronics through inductive discharge, even without direct contact.

To mitigate these risks, anti-static packaging is essential in environments where static-sensitive components are handled.

Products That Require Electrostatic Protection

The ESD Association recommends electrostatic discharge protection for products rated at 100 volts or higher, as these are more susceptible to static-related failures. Common products that require ESD-safe packaging include:

✔ Semiconductors & Microcircuits

✔ Computer Hardware & Components (CPUs, RAM, GPUs)

✔ Medical Devices & Equipment

✔ Flat-Screen Televisions & Monitors

✔ Aerospace & Automotive Electronics

Types of Anti-Static Packaging

Anti-static packaging products are available in stock and custom configurations to meet varying protection levels. Most anti-static materials are pink for easy identification, while conductive versions (which provide additional protection) are black.

✔ Anti-Static Poly Bags – Used for lightweight electronic parts and circuit boards.

✔ Anti-Static Bubble Bags & Rolls – Provides cushioning and static control for delicate electronics.

✔ Anti-Static Ziplocks & Tubing – Ideal for small components and moisture-sensitive devices.

✔ Anti-Static Foam – Custom-cut for impact protection and static prevention.

✔ Pallet Covers & Stretch Wrap – Shields bulk shipments from static exposure.

✔ Anti-Static Peanuts – Filler material that prevents static buildup inside packaging.

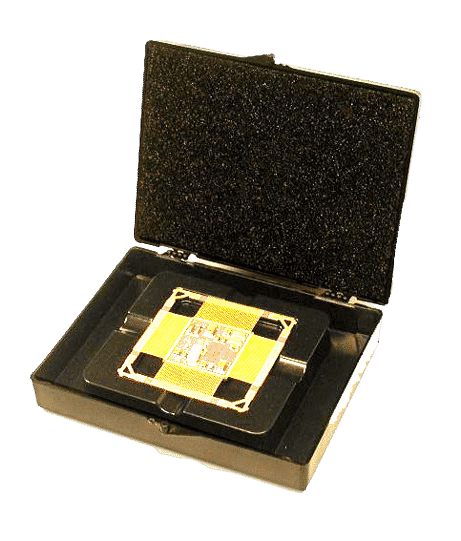

For high-value electronics, custom ESD-safe packaging solutions—such as die-cut foam inserts, shielding bags, and conductive corrugated boxes—can provide enhanced protection.

Benefits of Anti-Static Packaging

Investing in anti-static packaging safeguards your products and business operations. Key benefits include:

✔ Prevents Inventory Loss: Reduces damage and failures caused by electrostatic effects.

✔ Enhances Customer Satisfaction: Ensures product reliability, reducing complaints and returns.

✔ Saves Money on Repairs & Replacements: Minimizes costly product failures before reaching customers.

✔ Improves Product Shelf-Life & Durability: Prevents premature breakdown caused by static discharge.

✔ Meets Industry & Retail Compliance Standards: Ensures compatibility with regulatory and retailer ESD requirements.

✔ Reduces Safety Risks: Prevents fires, property damage, and injury in environments handling static-sensitive materials.

Where to Purchase Anti-Static & ESD Packaging

Not all packaging suppliers offer anti-static or conductive packaging. Many traditional packaging providers focus on standard solutions like corrugated boxes, foam, and poly bags without ESD protection.

At Brown Packaging, we supply businesses with anti-static, static-dissipative, and conductive packaging solutions, including custom and stock options. Whether you need static-safe bags, foam inserts, or complete ESD packaging systems, we can provide the right materials to protect your sensitive products.

📞 Contact Brown Packaging today to discuss your anti-static packaging needs and explore our full range of ESD protection solutions.

Many U.S. businesses currently sourcing packaging from China are facing a harsh reality: tariffs and trade volatility can quickly erode margins and disrupt supply chains.

Rising tariffs and trade restrictions on Chinese manufacturing are accelerating the need for U.S. companies to reevaluate their packaging supply chains. Many packaging buyers who

POP display design must serve two masters — maximizing visual impact in-store while minimizing logistics costs. Engineering the right balance between display footprint, assembly complexity,

Functional features like tear strips, windows, and hang tabs can enhance consumer experience and retail appeal—but they also introduce engineering challenges. Each modification affects structural

Phat Snax is redefining the snack aisle with a mission to make America’s snacks better for you — without killing the flavor. Their products, like

When choosing corrugated packaging, box style directly impacts cost, strength, speed of packing, and customer experience. Two of the most common options are the Regular

Home » Anti-Static Packaging and Electrostatic Discharge Explained

When it comes to retail marketing, Point of Purchase (POP) displays are essential for capturing customer attention and promoting your products effectively. The size and

In the world of packaging, the visual appeal of your product plays a significant role in catching the customer’s eye and leaving a lasting impression.

Whether you’re traveling with your bike, shipping it to a new location, or selling it, choosing the right bike shipping box is essential for safe