Home » What are Packaging Inserts and Why are They Important?

What are Packaging Inserts and Why are They Important?

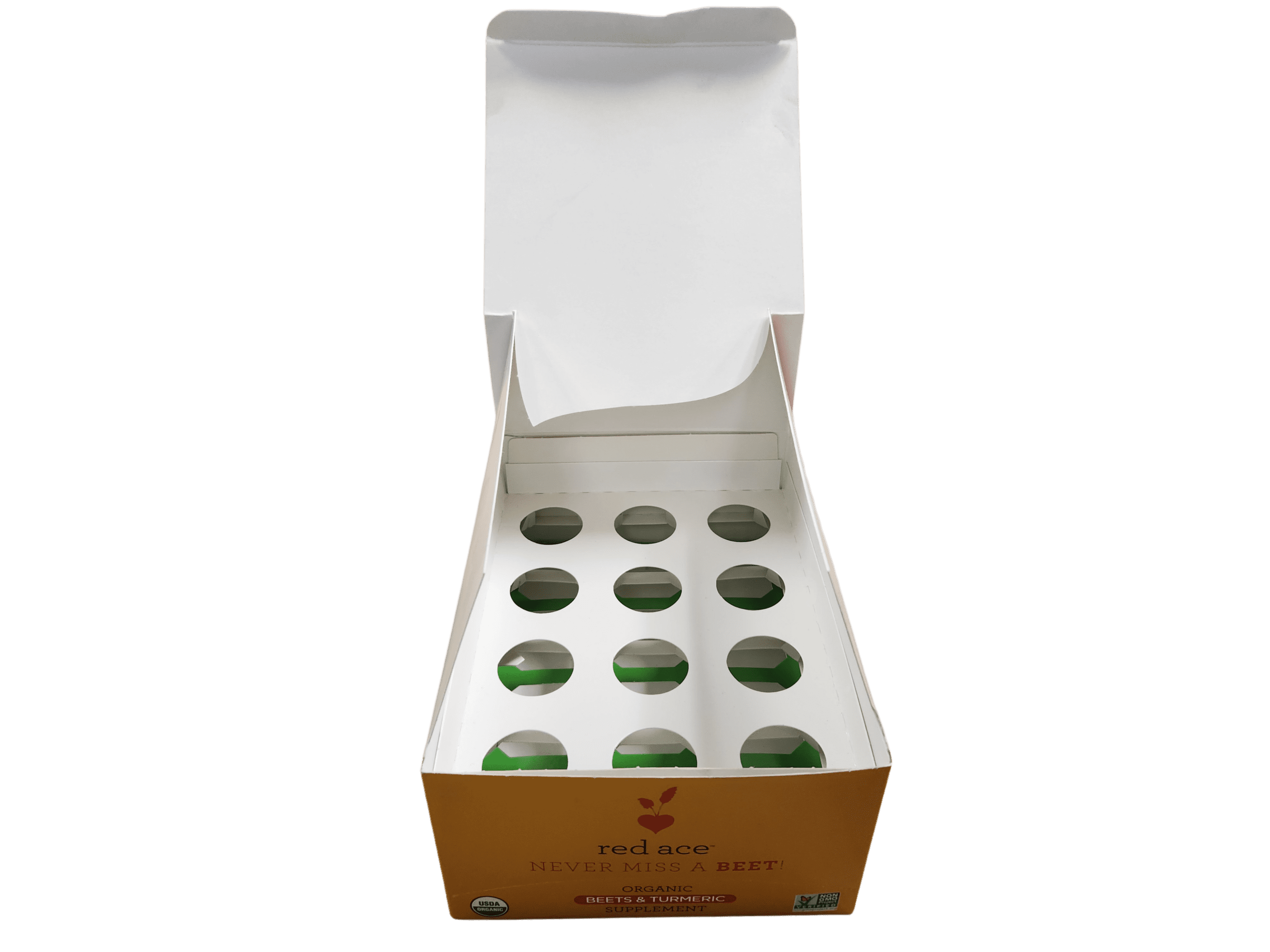

Packaging inserts, also known as inlays or box partitions, play a critical role in the packaging industry by enhancing product protection, presentation, and customer experience. They are designed to stabilize and secure products within a package, ensuring items are well-protected during transit and impeccably presented upon unboxing. Here’s an in-depth look at packaging inserts, their types, customization options, and why they are crucial for effective packaging solutions.

Understanding Packaging Inserts

Functionality of Packaging Inserts

Inserts are specifically crafted to limit and restrict the movement of one or multiple items within a package. They can be made from various materials, including foam, corrugated, paperboard, and thermoform plastics, each offering different levels of protection and aesthetic appeal. Whether in the form of trays or wall dividers, these inserts are essential for preventing product damage and enhancing the unboxing experience.

Types of Packaging Inserts

- Paperboard Inserts: Ideal for lightweight items such as cosmetics and electronic accessories. They provide basic protection and organization within the packaging.

- Corrugated Inserts: Offer enhanced durability and are suitable for small to medium weight products like light bulbs and small appliances.

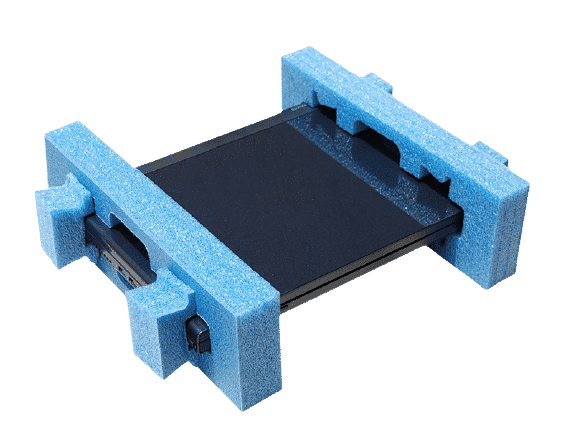

- Foam Inserts: Provide superior protection and are commonly used for fragile items, electronics, and sensitive instruments.

- Thermoform Inserts: Sturdy and rigid, these inserts are versatile for packaging a diverse range of products including food, medical supplies, and electronics.

Importance of Packaging Inserts

Protection and Security

The primary function of packaging inserts is to secure the packaged items robustly, ensuring they remain immobile and thus less susceptible to damage during shipping and handling. This is particularly important for fragile products or items with several components that need to be kept separate.

Enhanced Presentation

Custom inserts not only protect but also significantly enhance the presentation of products. They can be designed to fit the contours of specific items, displaying them in an appealing and organized manner that can elevate the customer’s perception of the brand.

Improved Customer Experience

Inserts contribute to a positive unboxing experience by presenting products in an organized and accessible way. They make unpacking simpler and more enjoyable, which can leave a lasting impression on consumers.

Customizing Packaging Inserts

Structural Design

Custom inserts can be tailored to the specific size and shape of the products they hold. Structural design ensures each product fits snugly within its compartment, providing optimal protection and a professional appearance.

Graphic Design

Inserts offer an additional surface for branding and communication. Custom graphics such as logos, product information, and brand colors can be added to inserts, furthering brand recognition and enhancing the aesthetic appeal of the packaging.

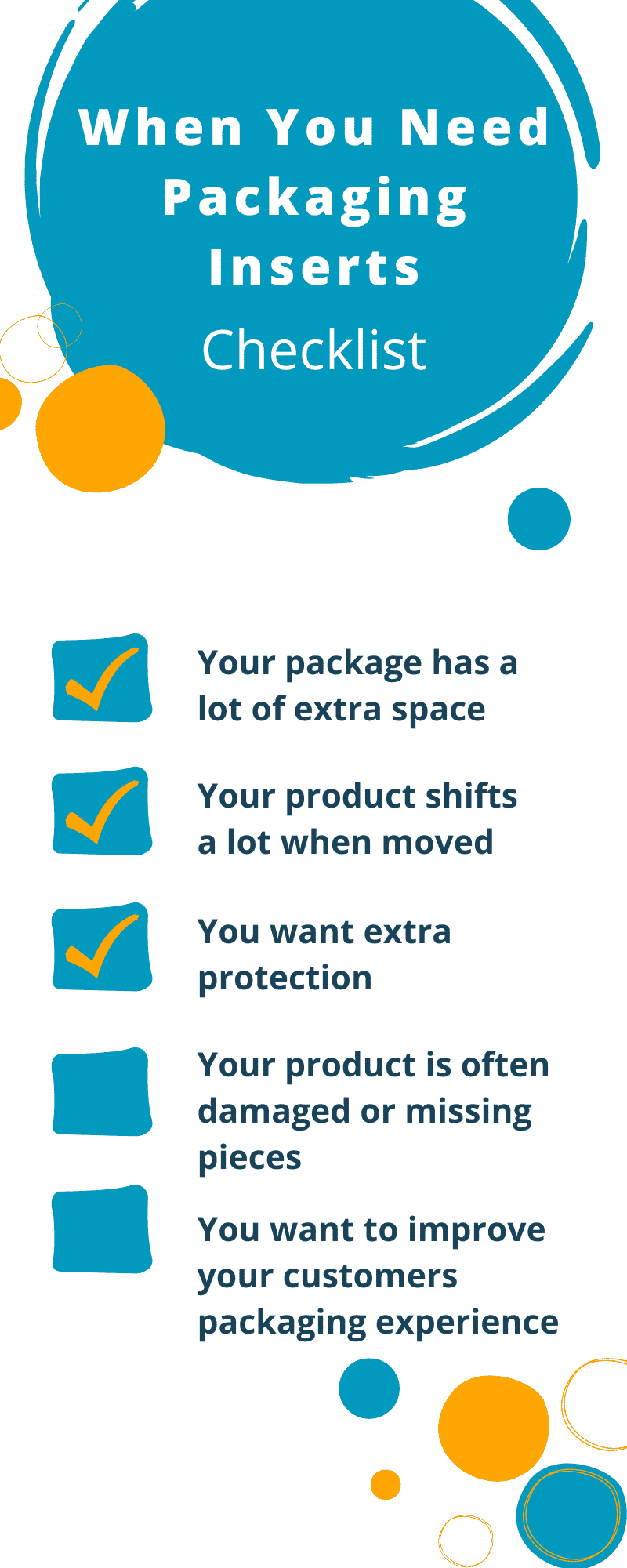

When Do You Need Packaging Inserts?

You should consider using packaging inserts if:

- You have fragile products that require additional protection.

- Your products have multiple components that need to be organized within the packaging.

- You are looking to improve the aesthetic presentation of your packaged products.

- Enhancing the customer unboxing experience is a priority for your brand.

Summary

Packaging inserts are vital components that help maintain the integrity and presentation of products during shipping and retail display. They not only protect items from physical damage but also play a significant role in brand perception and customer satisfaction. With various materials and customization options available, packaging inserts can be tailored to meet the specific needs of any product, making them a versatile and essential element in modern packaging strategies.

If you’re looking to develop customized packaging solutions that include high-quality inserts, consider partnering with a packaging expert like Brown Packaging. They can provide tailored advice and products designed to protect your goods effectively while promoting your brand effectively.

Premium packaging sells — until it doesn’t. In an environment where raw material costs, shipping rates, and consumer budgets all fluctuate, the smartest brands are

Dimensional (DIM) weight pricing has become a major driver of shipping costs in e-commerce and industrial supply chains. Carriers charge based on the greater of

The first quarter is a critical period for packaging buyers to reset supply levels after the holiday surge. Overstocking ties up capital, while understocking creates

Subscription packaging continues to expand across beauty, food, lifestyle, and specialty products. Buyers must balance branding, protection, and sustainability while keeping fulfillment efficient. This checklist

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss,

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In

Home » What are Packaging Inserts and Why are They Important?

In the world of packaging, the way a corrugated box is sealed and closed is as important as the box itself. The right type of

Shipping products safely and securely is a top priority for any business. During transit, packages are susceptible to various risks, including jostling, drops, and other

Packaging foam is essential for protecting products against shocks, vibrations, and other potential damages during transportation and storage. Understanding the different types of packaging foam