Sustainable Corrugated Boxes

Explore our selection of sustainable corrugated boxes, designed to cater to various packaging requirements. We provide multiple styles, eco-conscious materials, and sustainable ink/print options, ensuring each box meets both your needs and environmental standards. Opt for our tailored solutions to enhance your packaging’s impact and sustainability.

Sustainable Corrugated Boxes

Explore our selection of sustainable corrugated boxes, designed to cater to various packaging requirements.

How We Can Help Make Your Corrugated Box Sustainable

We specialize in providing sustainable corrugated box solutions that adhere to the highest environmental standards, including certifications from the FSC, SFI, RCS, and more. Let us help you meet your sustainability goals with our certified eco-friendly products and practices.

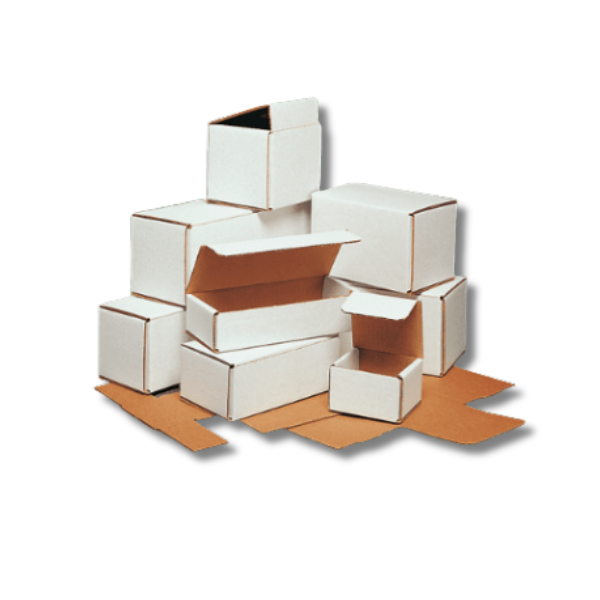

Corrugated Box Styles

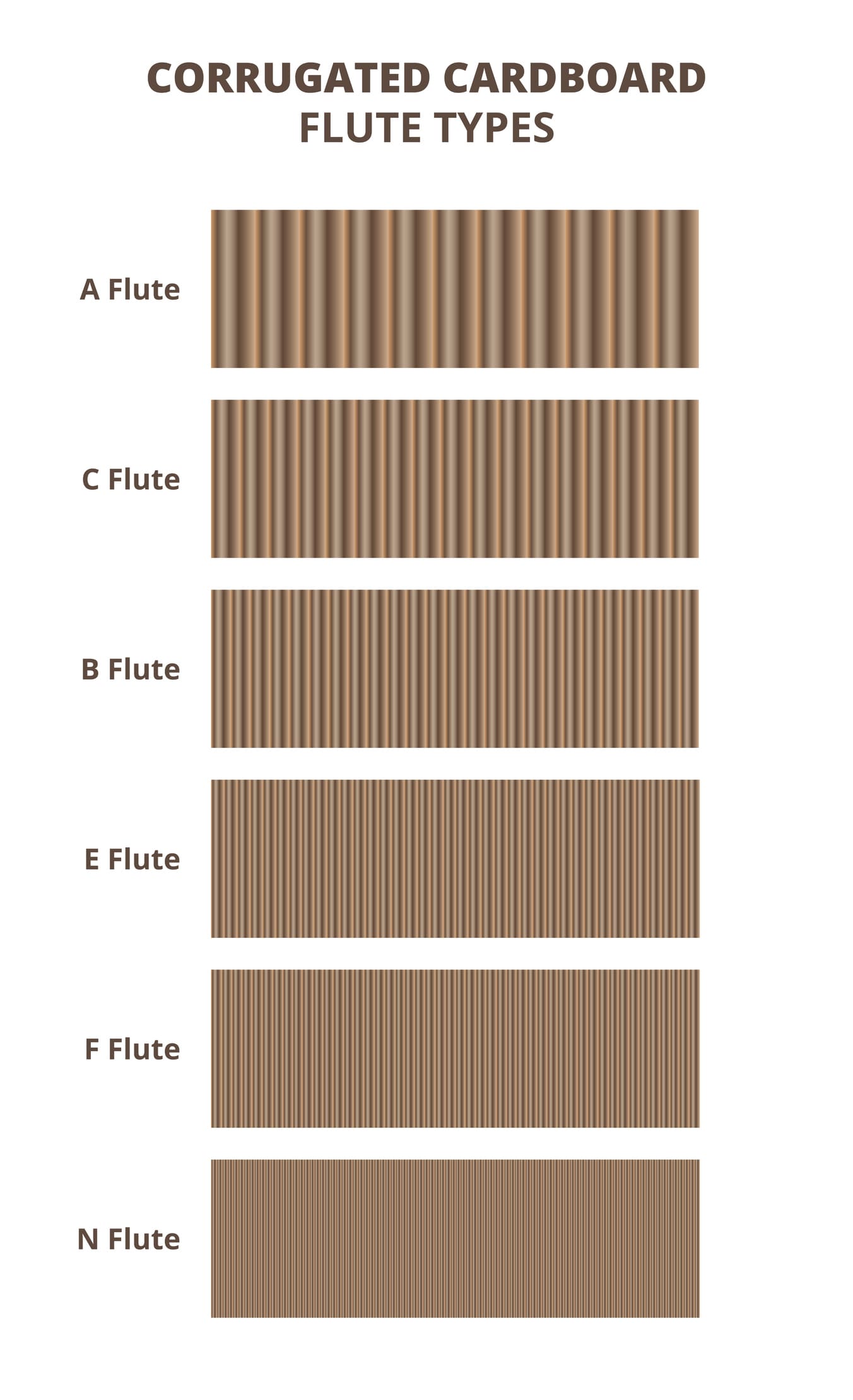

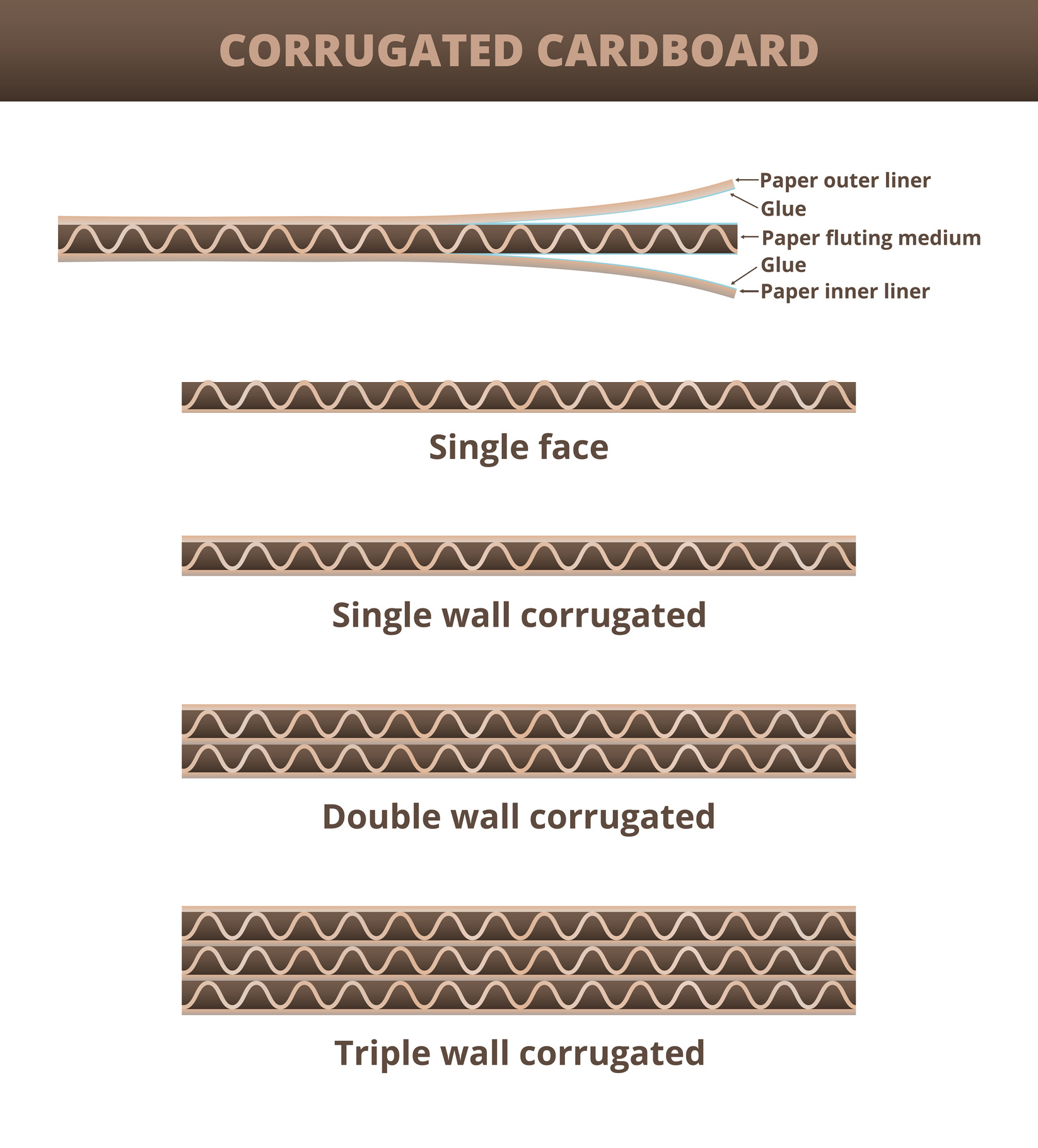

We offer a complete range of corrugated boxes, available in custom and stock options to suit your specific packaging needs. Our boxes are designed to meet various burst strengths and edge crush test (ECT) ratings, ensuring durability and reliability for your requirements.

The RSC is the most common style of corrugated box, featuring flaps of equal length from both the top and bottom, which meet in the center when folded. This design is versatile, economical, and ideal for a wide variety of products, providing reliable protection during shipping and storage.

RETT boxes are designed with a roll end that tucks into the top, providing a secure closure without the need for tape. They are commonly used for retail packaging due to their neat presentation and ease of access, making them ideal for shelf display.

An STE box features a bottom that can be quickly assembled with a snap-lock mechanism, offering security and durability. This style is frequently used for heavier items or products that require a more robust base for transport.

The RTE box has a top and bottom closure that tuck in opposite directions, which provides a simple and effective seal. This style is typically used for lighter products and offers a cost-effective solution for various packaging needs.

Trays are shallow platforms used for transporting and displaying products, especially useful in food service and retail environments. They are designed to be stackable and can be customized with dividers and covers to secure the contents.

Folders are a type of corrugated box that wraps around a product, providing a snug fit. They are excellent for books, framed items, or other flat products, offering a layer of protection that is reinforced by the corrugated folds.

If you’re looking for additional styles or have specific packaging requirements not covered in our listed options, please contact Brown Packaging. We offer a wide range of customizable corrugated box solutions and are dedicated to meeting your unique needs with precision and expertise.

Material Options

In our mission to support environmentally responsible practices, we offer corrugated boxes crafted from sustainable materials. These options not only ensure robust packaging but also contribute to reducing environmental impacts. Below are the sustainable materials we utilize:

Recycled Content

Renewable Resources

Sustainable Print and Ink Options

Explore our eco-friendly print and ink options for corrugated boxes, designed to ensure high-quality results while minimizing environmental impact. We use sustainable inks and printing processes that reduce harmful emissions and are safer for the environment, providing you with a greener choice without compromising on visual appeal.

Digital printing stands out for its direct from digital file to print capability, which eliminates the need for printing plates, reducing waste and setup times. This method is highly efficient for short runs and customized printing, making it ideal for on-demand and variable data projects. Digital printing uses less energy and fewer chemicals than traditional methods, reducing environmental impact.

- Applicable to: Small to medium print runs, customized packaging, high-quality detail.

- Sustainability Level: High, due to reduced waste and lower consumption of energy and materials.

Flexographic printing uses flexible printing plates and fast-drying, primarily water-based inks, making it suitable for a wide range of substrates and large volume runs. This method combines high efficiency with adaptability and is particularly valued in the packaging industry for its speed and cost-effectiveness for long print runs. While flexographic printing involves more setup compared to digital, advancements have made it more eco-friendly with the use of water-based inks and improved plate technology.

- Applicable to: Large print runs, continuous patterns, packaging films, labels, and corrugated materials.

- Sustainability Level: Moderate to High, depending on ink choice and operational efficiency improvements.

Lithographic printing, also known as offset printing, is renowned for its high-quality image reproduction and efficiency in high-volume tasks. This method uses plates that transfer an image onto a rubber blanket and then to the printing surface, typically involving oil-based inks. Lithographic printing is less favorable in terms of environmental impact due to higher VOC emissions and the extensive use of chemicals and water in the process.

- Applicable to: High-volume print runs, publications, detailed artistic prints, and quality packaging.

- Sustainability Level: Lower, due to higher resource usage and VOC emissions compared to other methods.

Digital printing stands out for its direct from digital file to print capability, which eliminates the need for printing plates, reducing waste and setup times. This method is highly efficient for short runs and customized printing, making it ideal for on-demand and variable data projects. Digital printing uses less energy and fewer chemicals than traditional methods, reducing environmental impact.

- Applicable to: Small to medium print runs, customized packaging, high-quality detail.

- Sustainability Level: High, due to reduced waste and lower consumption of energy and materials.

Soy-Based Inks utilize soy oil, allowing deeper color saturation and easier recycling compared to petroleum-based inks. While they provide excellent print quality and environmental benefits, soy-based inks generally cost more than traditional inks and may offer slower drying times, which can affect production speed. Additionally, they are sometimes limited in resistance to water and abrasion, requiring careful handling and specific applications.

- Applicable to: Lithographic printing where print quality and environmental considerations are important.

- Sustainability Level: High, due to their renewable nature and reduced emissions.

- Cost Level: Slightly higher than traditional inks, justified by environmental benefits.

- Advantages: Enhances recyclability, vibrant colors, reduces environmental impact, supports sustainability.

- Disadvantages: Higher cost, slower drying times than other inks, and potential limitations in water and abrasion resistance.

Water-Based Inks are chosen for their safety and low environmental impact. These inks use water as the solvent, reducing volatile organic compounds (VOCs) emissions and enhancing workplace safety. They are suitable for high-speed printing processes due to their quick drying by absorption into the substrate. Water-based inks provide vibrant colors and good adhesion but may pose challenges in terms of achieving the same level of vibrancy and durability as solvent-based inks.

- Applicable to: Flexographic and digital printing for corrugated boxes.

- Sustainability Level: High, as they minimize harmful emissions and are safe for use in various industries, including food.

- Cost Level: Moderate, generally more affordable than UV-curable inks but can vary based on formulation.

- Advantages: Eco-friendly, reduces VOC emissions, quick drying, cost-effective for large runs.

- Disadvantages: May have limited color saturation and durability compared to solvent-based inks, sensitive to environmental conditions like humidity.

UV-Curable Inks are notable for their durability and quality, instantly curing under UV light to create a robust, smudge-resistant finish. They are ideal for high-quality graphic displays on retail packaging. Despite their advantages, UV-curable inks require specific equipment and high energy consumption for curing, which can increase operational costs. Their formulation can also be less eco-friendly compared to other inks if not properly managed.

- Applicable to: Digital and lithographic printing for high-quality graphic corrugated boxes.

- Sustainability Level: Moderate, significantly reducing solvent emissions.

- Cost Level: Higher, due to energy use in curing and the need for specific equipment.

- Advantages: Excellent durability, superb print quality, effective on various substrates, instant curing reduces lead time.

- Disadvantages: Higher initial setup and operating costs, potential environmental impact from energy use, and the need for specialized curing equipment.

Soy-Based Inks utilize soy oil, allowing deeper color saturation and easier recycling compared to petroleum-based inks. While they provide excellent print quality and environmental benefits, soy-based inks generally cost more than traditional inks and may offer slower drying times, which can affect production speed. Additionally, they are sometimes limited in resistance to water and abrasion, requiring careful handling and specific applications.

- Applicable to: Lithographic printing where print quality and environmental considerations are important.

- Sustainability Level: High, due to their renewable nature and reduced emissions.

- Cost Level: Slightly higher than traditional inks, justified by environmental benefits.

- Advantages: Enhances recyclability, vibrant colors, reduces environmental impact, supports sustainability.

- Disadvantages: Higher cost, slower drying times than other inks, and potential limitations in water and abrasion resistance.

Water-Based Inks are chosen for their safety and low environmental impact. These inks use water as the solvent, reducing volatile organic compounds (VOCs) emissions and enhancing workplace safety. They are suitable for high-speed printing processes due to their quick drying by absorption into the substrate. Water-based inks provide vibrant colors and good adhesion but may pose challenges in terms of achieving the same level of vibrancy and durability as solvent-based inks.

- Applicable to: Flexographic and digital printing for corrugated boxes.

- Sustainability Level: High, as they minimize harmful emissions and are safe for use in various industries, including food.

- Cost Level: Moderate, generally more affordable than UV-curable inks but can vary based on formulation.

- Advantages: Eco-friendly, reduces VOC emissions, quick drying, cost-effective for large runs.

- Disadvantages: May have limited color saturation and durability compared to solvent-based inks, sensitive to environmental conditions like humidity.

UV-Curable Inks are notable for their durability and quality, instantly curing under UV light to create a robust, smudge-resistant finish. They are ideal for high-quality graphic displays on retail packaging. Despite their advantages, UV-curable inks require specific equipment and high energy consumption for curing, which can increase operational costs. Their formulation can also be less eco-friendly compared to other inks if not properly managed.

- Applicable to: Digital and lithographic printing for high-quality graphic corrugated boxes.

- Sustainability Level: Moderate, significantly reducing solvent emissions.

- Cost Level: Higher, due to energy use in curing and the need for specific equipment.

- Advantages: Excellent durability, superb print quality, effective on various substrates, instant curing reduces lead time.

- Disadvantages: Higher initial setup and operating costs, potential environmental impact from energy use, and the need for specialized curing equipment.

Interested In Sustainable Corrugated Packaging?

Frequently Asked Questions

Learn more about sustainable corrugated boxes, including style options, order minimums, lead time and more. Discover information to help you make informed decisions about eco-friendly packaging solutions tailored to your needs.

Expert Consulting

Our expert consulting services provide tailored guidance and strategic insights to help you make informed packaging decisions and optimize your packaging processes.

Digital Print

Utilizing advanced in-house digital printing technology, we offer high-quality printed samples that showcase your packaging design concepts effectively.

Structural Design

Our structural design expertise ensures your packaging is not only visually appealing but also optimized for functionality, protection, and cost-efficiency.

Sampling

We provide sampling services to help you evaluate and refine your packaging prototypes, allowing you to make data-driven decisions before full-scale production.

Graphic Design

Our graphic design team specializes in creating captivating visuals, ensuring your packaging communicates your brand identity and product messaging effectively.

Product & Material testing

We offer comprehensive product and material testing to guarantee the durability, safety, and compliance of your packaging, assuring its suitability for your specific industry and requirements.

Order minimums vary from project to project, it usually depends on the type of packaging, design, size and desired materials. Contact us and we will evaluate the best options for your packaging needs.

Shipping is free to all Southern California businesses. Fees are generally added to orders outside of Southern California or if you need a rush order. We also deliver to all of the United States, in which prices for shipping can vary.

Yes, we offer both custom and stock corrugated boxes to meet a variety of needs and specifications. Whether you require standard sizes for general use or customized solutions tailored to unique product dimensions and branding requirements, we have the capability and expertise to provide high-quality corrugated boxes that perfectly suit your needs. Feel free to contact us to discuss your specific requirements and explore our extensive range of options.

Selecting the right style of corrugated box is crucial as it ensures optimal protection, enhances cost-effectiveness, and meets specific logistical requirements, ultimately safeguarding your product’s integrity throughout the shipping and handling process.

We Are Retail Compliant:

We ensure our corrugated boxes meet the packaging standards of major retailers like Amazon, Target, and Home Depot, aligning with their specific guidelines to facilitate compliance and streamline distribution. Our adherence to these standards helps clients optimize market reach and avoid repackaging costs.

We Are Gov. Compliant:

Our corrugated boxes comply with government regulations set by the FDA, EPA, CPSC, TSA, OSHA, DTSC (California), CPR (California), and more, ensuring adherence to stringent safety and environmental standards. This compliance supports a seamless distribution process across various sectors, protecting both products and consumers.

To dive deeper into sustainable packaging, we invite you to explore our blog, which features a wealth of information on eco-friendly practices, innovations in sustainable materials, and expert insights. Our blog is regularly updated to help you stay informed about the latest trends and developments in sustainable packaging. Visit our blog to learn more and take your knowledge to the next level.

As environmental concerns continue to dominate consumer and regulatory conversations, the packaging industry is responding with innovative, eco-friendly solutions. In 2025, sustainable packaging will not

Sustainability in pet food packaging is not just about recyclability—it’s about reducing environmental impact across the entire lifecycle. For products with high barrier needs like

In today’s market, the concept of ethical packaging has become increasingly important. Companies are recognizing the need to adopt packaging practices that are not only