Home » Shock Absorption Properties in Foam Packaging

Shock Absorption Properties in Foam Packaging

In the realm of packaging, the safe transport and protection of delicate and fragile items are paramount. Foam materials serve as the frontline defense in ensuring that products remain intact throughout the rigors of transportation and handling. This comprehensive guide delves into the pivotal role of shock absorption properties in foam packaging, their profound impact on product protection, and the key considerations when selecting the ideal foam for your packaging needs.

Understanding Shock Absorption Properties

Before delving into the importance of shock absorption properties, it’s vital to grasp their essence. Shock absorption properties in foam packaging are primarily concerned with the foam’s ability to dissipate and absorb energy when subjected to sudden impacts or shocks. These properties encompass two key aspects:

Compression Deflection (Firmness): This metric gauges the force required to compress a foam material by a specified percentage of its original thickness. It dictates the foam’s firmness and its resistance to deformation under load.

Compression Set: Compression set assesses the foam’s capacity to regain its initial shape after being compressed. It quantifies the foam’s ability to rebound to its original form once the external pressure is removed.

The Role of Shock Absorption Properties

Safeguarding Against Impact and Shock

The primary role of foam in packaging is to act as a protective barrier, shielding products from the perils of impact and shock during transit and handling. The compression deflection of foam directly influences its aptitude for absorbing and dissipating the energy generated by these impacts. Foam with well-suited compression deflection properties significantly mitigates the risk of damage to packaged goods, ensuring their pristine condition upon arrival.

Preserving Product Integrity

For fragile and sensitive products, maintaining their structural integrity is of paramount importance. A foam with appropriate compression set properties guarantees that, even after experiencing compression during packaging or transit, the foam will faithfully revert to its original shape. This characteristic holds particular significance for products with intricate shapes or those that necessitate secure placement within the packaging.

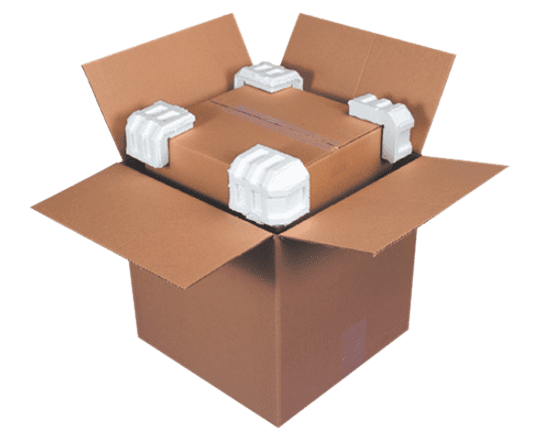

Uniform Distribution of Forces

In certain instances, packaged items may endure prolonged periods of compression, whether due to stacking in storage or during transit. The shock absorption properties of foam become crucial in such scenarios. Foam materials that boast well-matched compression deflection and compression set characteristics serve to evenly distribute the load, averting uneven pressure points that could culminate in deformation or harm to the packaged items.

Customization and Versatility

Packaged items come in diverse forms and dimensions, necessitating adaptable packaging solutions. By selecting foam with the appropriate shock absorption properties, packaging designers can ensure that the foam seamlessly conforms to the unique contours and fragility of each item. This tailored approach to protection is a hallmark of effective foam packaging.

Choosing the Optimal Foam Material

The process of selecting the right foam material with fitting shock absorption properties involves a comprehensive evaluation of your packaging prerequisites and the fragility of the products in question. Key considerations encompass:

- Product Weight: Bulkier items may necessitate foam with a higher compression deflection to withstand the load without undergoing deformation.

- Product Fragility: Items susceptible to breakage or damage benefit significantly from foam with suitable compression deflection and compression set properties, effectively absorbing and recuperating from shocks.

- Packaging Configuration: The design and structure of your packaging play a pivotal role in determining the foam’s shock absorption requisites. Tailored foam inserts can be instrumental in optimizing protection.

- Environmental Conditions: Contemplate the environmental conditions to which the packaged items will be exposed. Some foam materials are better suited for extreme temperatures or conditions involving moisture.

- Budgetary Considerations: Strike a balance between your packaging needs and budget constraints. Different foam materials may come at varying costs, so select one that aligns with your requirements without exceeding your budget.

If you are interested in foam packaging solutions, then partner with Brown Packaging today to get started.

Choosing the right packaging material is one of the most important decisions buyers face. Single-material packaging offers simplicity and recyclability, while multi-material designs provide enhanced

One of the biggest challenges in sustainable packaging is balancing environmental responsibility with product protection. Buyers often worry that switching to eco-friendly materials means sacrificing

In today’s competitive market, packaging affordability doesn’t start with cheaper materials — it starts with smarter design. Every score, fold, and insert decision affects not

Every brand is feeling the squeeze — higher raw material costs, volatile freight rates, and a consumer base more price-conscious than ever. But cutting packaging

Corrugated board comes in multiple flute sizes and wall grades, each designed to balance strength, weight, and cost. Selecting the wrong grade can lead to

As tariff changes reshape global trade, packaging buyers moving production from China to the U.S. or nearshore regions face a new challenge: supplier qualification. Transitioning

Home » Shock Absorption Properties in Foam Packaging

The fascinating world of protective packaging has seen considerable evolution over the decades. These advancements have been driven by the needs of various industries, emerging

Packaging is an integral part of the overall customer experience, providing protection, information, and branding to the products we buy. However, when it comes to

Packaging is the first line of defense for your products, shielding them from the hazards they may encounter during storage, handling, and transportation. One of