Home » Unveiling the Power of Custom Packaging in Brand Storytelling

Unveiling the Power of Custom Packaging in Brand Storytelling

In the realm of marketing, storytelling has evolved into a potent tool for brands to forge meaningful connections with consumers. Beyond the mere sale of products, brands are now focused on offering experiences and emotions. One pivotal avenue for achieving this is through the art of custom packaging. In this blog, we’ll delve deep into the captivating world of custom packaging and how it transforms into a canvas for brand storytelling, allowing businesses to convey their essence, values, and unique narrative.

Packaging Beyond Protection: The Unfolding Story

Traditionally, packaging has been regarded as a functional necessity, primarily tasked with safeguarding and containing a product. While these foundational roles are undeniably essential, custom packaging transcends utility to become a strategic canvas for storytelling.

Reflecting Brand Identity

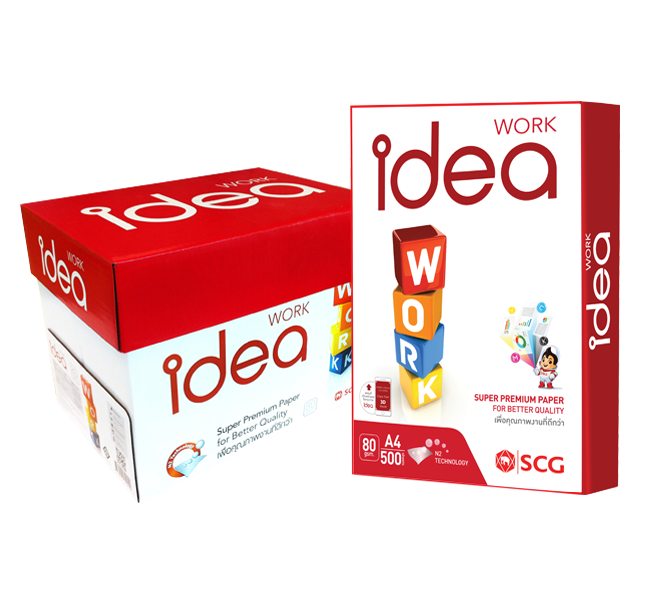

Custom packaging serves as the first touchpoint between your product and consumers. It’s the initial glimpse into your brand universe. To craft an unforgettable experience, every facet of your packaging design should resonate with your brand’s identity. Delve deep into your brand’s personality and values. Do the design elements, color schemes, and typography echo your brand essence? For instance, if your brand is synonymous with eco-friendliness, your custom packaging should speak volumes through sustainable materials and environmentally-conscious design choices.

Telling the Brand’s Origin Story

Consumers are drawn to stories – particularly the stories behind the products they purchase. Custom packaging becomes the storyteller that narrates your brand’s history, its evolution, and the passion that fuels it. Contemplate including a succinct narrative on your packaging that shares the origin story of your brand, its mission, or the driving force behind your products. This personal touch fosters a deeper emotional bond with consumers, making them feel like they are part of your brand’s journey.

Showcasing Product Benefits

Your custom packaging should also act as a stage to spotlight the merits and unique features of your product. Employ concise and compelling language to articulate how your product can enhance the consumer’s life. Whether it’s convenience, quality, or unparalleled characteristics, ensure these messages are crystal clear and persuasive on your packaging.

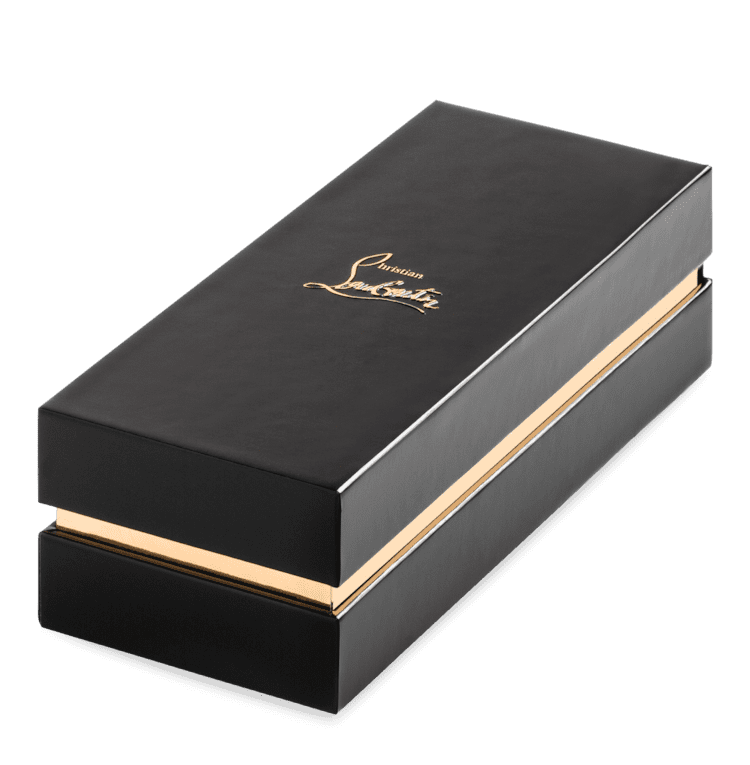

Creating an Unboxing Experience

In the digital age, unboxing has evolved into a phenomenon. Consumers relish sharing their unboxing experiences on social media, and custom packaging can take center stage in this theatrical performance. Ponder how your packaging can elevate the thrill of unwrapping your product. Consider thoughtful additions such as delicately crafted tissue paper, branded stickers, or personalized thank-you notes to fashion a memorable unboxing ceremony.

Demonstrating Sustainability

Sustainability is an ever-mounting concern for consumers. Custom packaging can serve as a powerful canvas to showcase your unwavering commitment to eco-friendliness. By employing eco-conscious materials, spotlighting your sustainable practices, and transparently communicating your dedication to reducing your environmental footprint through your packaging, you not only tell a sustainability story but also underscore your brand’s integrity.

Conclusion: Custom Packaging as a Dynamic Storytelling Medium

In the fiercely competitive market landscape, brand storytelling is not merely a marketing strategy; it’s a necessity. Custom packaging emerges as a dynamic storytelling medium that transcends its practical role. It becomes an extension of your brand’s character, values, and narrative. By meticulously crafting your custom packaging to mirror your brand identity, narrate your story, and orchestrate a memorable unboxing spectacle, you don’t just safeguard your product – you engage and connect with consumers on a profound level. In essence, custom packaging evolves into your brand’s storyteller, inviting consumers to unravel the captivating narrative behind your products and become active participants in your brand’s saga.

If you are interested in custom packaging, then partner with Brown Packaging today.

Full Overlap (FOL) corrugated boxes are valued for their durability, with overlapping flaps that add protection on the top and bottom panels. But the strength

Full Overlap (FOL) corrugated boxes are engineered for strength. Unlike a Regular Slotted Container (RSC), the major flaps on an FOL extend the full width

Product damage during transit is one of the most significant hidden costs in packaging. Each damaged shipment increases returns, erodes customer trust, and raises overall

Moisture and humidity can weaken paperboard fibers, alter structural performance, and compromise print quality. From production to end use, controlling these factors is critical to

Flexible pouches rely on laminates to deliver strength, barrier protection, and shelf appeal. A laminate is a structure made by combining multiple film layers—each selected

Peak season shipping volumes put pressure on every part of the supply chain. For packaging buyers, right-sizing boxes is one of the most effective strategies

Home » Unveiling the Power of Custom Packaging in Brand Storytelling

For retail brands, Point of Purchase (POP) displays are crucial for maximizing product visibility and driving sales. Ensuring that these displays are retail-ready is key

Rigid boxes, known for their durability and premium appearance, are a popular choice for packaging high-end products. However, the perception of being expensive can deter

Packaging design is a crucial aspect of any product’s marketing strategy. It serves as a visual ambassador for your brand and plays a pivotal role