Home » Custom Packaging: Everything You Need to Know and More

Custom Packaging: Everything You Need to Know and More

Custom packaging is the process of creating unique and personalized packaging materials tailored to the specific requirements of a product, brand, or business. In today’s crowded marketplace, custom packaging plays a crucial role in enhancing the overall customer experience, promoting brand recognition, and setting businesses apart from their competitors. In this blog, we will delve deeper into custom packaging, explore its benefits, types, considerations, and additional information that businesses need to know to make informed decisions about their packaging needs.

Why Custom Packaging is Important?

Custom packaging provides businesses with numerous benefits, such as improved brand identity, product protection, marketing, and sustainability. Custom packaging is essential for businesses because it:

- Enhances Brand Identity: Custom packaging allows businesses to create packaging designs that align with their brand identity, values, and messaging. By creating unique and consistent packaging, businesses can create a lasting impression on their customers and set themselves apart from their competitors.

- Ensures Product Protection: Custom packaging is designed to protect the product during transportation and storage. Custom packaging ensures that the product arrives at the customer’s doorstep in perfect condition, leading to customer satisfaction and loyalty.

- Improves Marketing Efforts: Custom packaging can be used as a marketing tool to promote the brand, communicate product information, and increase customer engagement. Custom packaging creates a memorable experience for customers, making it an effective way to communicate brand values and messaging.

- Supports Sustainability Efforts: Custom packaging allows businesses to choose eco-friendly materials, reduce waste, and promote their commitment to sustainability. In today’s world, customers are environmentally conscious, making sustainability an important factor for businesses to consider.

Types of Custom Packaging

Businesses have numerous options when it comes to custom packaging. Depending on the product and business requirements, there are different types of custom packaging solutions available. Some popular types of custom packaging are:

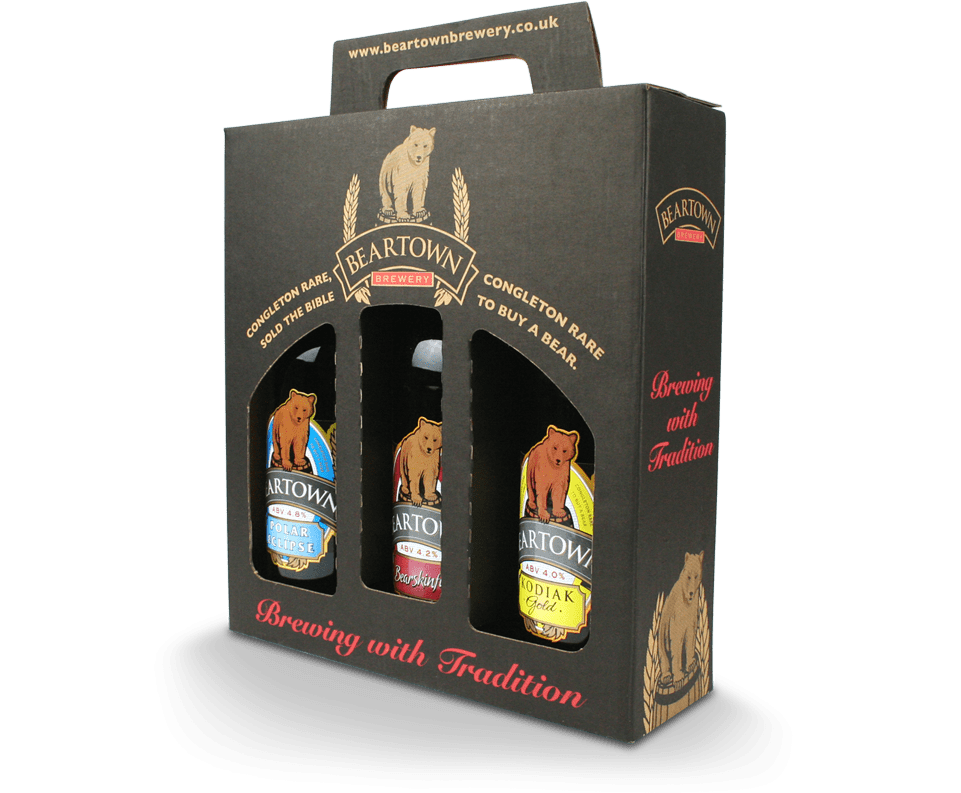

Printed Boxes

Printed boxes are a cost-effective and customizable packaging solution for various products, including food, cosmetics, and electronics. They can be customized with various printing options, including logos, images, and product information. Printed boxes come in different sizes, shapes, and materials (chipboard, paperboard and corrugated), making them versatile and suitable for different products.

Custom Bags

Custom bags are an excellent packaging option for retail businesses, restaurants, and food delivery services. They can be made from different materials, including paper, plastic, and fabric, and customized with branding and design elements. Custom bags are easy to carry, lightweight, and convenient for customers, making them a popular choice for businesses.

Custom Labels

Custom labels are an essential component of custom packaging and can be used to display product information, branding, and marketing messages. They can be made from various materials, including paper, vinyl, and polyester, and come in different sizes, shapes, and finishes. Custom labels can be applied to different packaging materials, including boxes, bags, and jars.

Custom Inserts

Custom inserts are designed to protect and secure the product inside the packaging. They can be made from different materials, including foam, corrugated, plastic and molded pulp, and customized to fit the product’s dimensions. Custom inserts ensure that the product is safe and secure during transportation, reducing the risk of damage.

Custom Tubes

Custom tubes are a popular packaging option for products such as cosmetics, pharmaceuticals, and food items. They can be made from various materials, including paper, plastic, and metal, and customized with different printing options. Custom tubes are durable, convenient, and easy to use, making them a preferred choice for many businesses.

Considerations for Custom Packaging

When designing custom packaging, businesses need to consider various factors, such as product requirements, budget, materials, design, and sustainability. By taking these factors into account, businesses can create custom packaging solutions that align with their values, meet their specific requirements, and promote their brand identity effectively. Some additional considerations for custom packaging are:

Product Compatibility

The packaging material should be compatible with the product it is intended to protect. Businesses need to consider factors such as product fragility, moisture resistance, and temperature control to ensure that the packaging material is suitable for the product.

Packaging Size

The packaging size should be appropriate for the product, ensuring that it is neither too loose nor too tight. A packaging size that is too small can damage the product, while a packaging size that is too large can lead to unnecessary material waste.

Budget and Cost-Effectiveness

Custom packaging can be expensive, and businesses need to determine their budget and cost-effectiveness of the packaging solution. It is essential to strike a balance between cost and quality to ensure that the custom packaging solution meets the business’s specific requirements and is cost-effective.

Materials

The materials used for custom packaging should be eco-friendly, sustainable, and aligned with the business’s values and messaging. Businesses should consider materials such as recycled paper, biodegradable plastics, and natural fibers to promote sustainability and environmental consciousness.

Design and Branding

The packaging design should be visually appealing, consistent with the brand identity, and convey the product information and marketing messages effectively. Custom packaging design should be eye-catching and memorable, ensuring that the packaging creates a lasting impression on customers.

Custom Packaging Regulations

Businesses should be aware of the regulatory requirements for custom packaging, such as food safety regulations, labeling requirements, and environmental regulations. Compliance with these regulations ensures that the custom packaging solution is safe, legally compliant, and sustainable.

Impact on Customer Experience

Custom packaging plays a significant role in enhancing the overall customer experience. Businesses should consider how their custom packaging solutions impact the customer experience, such as how easy it is to open, how the packaging feels in the hands, and how well it protects the product.

Logistics and Transportation

Businesses should consider the logistics and transportation requirements of their custom packaging solutions. Factors such as packaging weight, dimensions, and materials can impact shipping costs, transportation logistics, and storage.

Summary: Custom Packaging

In conclusion, custom packaging is a valuable investment that can enhance the overall customer experience, promote brand recognition, and support sustainability efforts. Businesses should carefully consider product requirements, budget, materials, design, sustainability, and additional considerations when choosing a custom packaging solution. By creating custom packaging solutions that align with their values, meet their specific requirements, and promote their brand identity effectively, businesses can differentiate themselves in a crowded marketplace and create a memorable customer experience.

If you are interested in custom packaging solutions, then partner with Brown Packaging today to get started.

As budgets tighten in 2026, packaging buyers are under pressure to reduce costs without increasing damage rates. Cutting too aggressively can lead to product loss, higher return rates, and frustrated customers. The key is balancing material use, box design, and supply chain efficiency so that savings do not come at the expense of protection. Where Packaging Costs Add Up Oversized boxes: Drive dimensional weight charges. Excess materials: Overuse of void fill and inserts. Complex SKU mix: Redundant sizes increase inventory costs. Inefficient freight: Poor palletization and stacking. Cost-Saving Strategies That Maintain Protection Right-sizing: Match box size to product dimensions to cut DIM charges and material use. Optimize corrugated grades: Switch to single- or double-wall where appropriate without compromising strength. Consolidate SKUs: Streamline packaging options to reduce inventory overhead. Efficient inserts: Replace foam or excess dunnage with engineered corrugated or molded pulp. Supplier contracts: Negotiate based on annual volumes, not just peak season orders. Testing Before Implementing Changes Use ASTM and ISTA protocols to ensure changes won’t increase product damage. Test for compression, vibration, and drop resistance. Run pilot shipments before scaling across the supply chain. Balancing Sustainability and Cost Eco-friendly doesn’t have to mean expensive: Use recyclable coatings to reduce plastic films. Choose corrugated designs that require less material while maintaining stacking strength. Highlight sustainable solutions in marketing to offset cost concerns. Packaging Solutions with Brown Packaging Brown Packaging helps companies lower costs while protecting products across the supply chain. From SKU rationalization to right-sized corrugated solutions, our team ensures packaging savings don’t compromise performance. Contact us to optimize your packaging program. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.Sustainable Packaging Coalition. (2023). Packaging Efficiency and Waste Reduction Report. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Product damage is one of the most expensive risks in packaging. Beyond replacement costs, damaged goods lead to lost sales, returns, and reputational harm. In 2026, complex e-commerce, global shipping, and automation create new challenges for packaging buyers. The right materials, testing, and design strategies are critical to protecting products while controlling costs. Why Damage Prevention Matters Financial losses: Damaged products increase replacement and freight costs. Customer impact: Poor delivery experience reduces loyalty and repeat sales. Sustainability: Returns and waste drive higher carbon footprints. Compliance: Retailers often impose penalties for damaged shipments. Common Causes of Product Damage Compression: Pallet stacking weakens boxes in transit. Vibration and shock: Long-haul shipping increases risk. Moisture exposure: Humidity and rain compromise corrugated performance. Poor right-sizing: Oversized boxes allow product movement inside. Strategies to Reduce Damage in 2026 Right-size packaging: Minimize empty space and movement. Material optimization: Choose the correct corrugated grade for load demands. Protective inserts: Molded pulp or engineered corrugated reduce shock. Moisture-resistant coatings: Defend against water and humidity. Automation-friendly design: Prevent jams that damage products on high-speed lines. Testing Protocols for Damage Prevention ISTA testing: Simulates vibration, drops, and compression. ASTM standards: Validate packaging strength and durability. Pilot shipments: Real-world trials confirm lab results. Packaging Solutions with Brown Packaging Brown Packaging designs solutions that minimize damage across today’s complex supply chains. From right-sized corrugated to ISTA-tested inserts, we help buyers protect products while reducing costs. Contact us to strengthen your packaging program. References ASTM International. (2023). ASTM D4169: Standard Practice for Performance Testing of Shipping Containers and Systems.International Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Retail packaging continues to evolve as brands balance sustainability, supply chain performance, and consumer experience. In 2026, buyers face new challenges shaped by material innovation, compliance requirements, and rising consumer expectations. Understanding these trends helps companies stay competitive while aligning packaging programs with industry standards. Sustainability Becomes Non-Negotiable Greater use of recyclable and compostable substrates. Retailers pushing suppliers toward FSC-certified materials. Minimalist designs that reduce waste without losing impact. Smarter Packaging for Supply Chains Increased adoption of right-sizing to reduce freight costs. Boxes designed for automation and faster fulfillment. Stronger corrugated grades to withstand long e-commerce journeys. Enhanced Consumer Experience Custom graphics for seasonal campaigns and limited editions. Tear strips, resealable closures, and window cutouts for convenience. Premium finishes that elevate gift packaging at retail. Growth of Hybrid Packaging Formats Combining corrugated strength with folding carton graphics. Modular designs for multi-SKU and club store environments. Packaging engineered to serve both e-commerce and in-store needs. Compliance and Testing Standards Retailers demanding ISTA and ASTM testing for packaging durability. Supply chain audits on recyclability and sustainability claims. More pressure for transparent reporting on environmental impact. Retail Packaging Solutions with Brown Packaging Brown Packaging helps brands adapt to evolving retail packaging trends. From sustainable substrates to automation-friendly designs, our solutions balance branding, durability, and compliance for 2026. Contact us to prepare your packaging program for the year ahead. References Forest Stewardship Council (FSC). (2023). FSC Packaging Certification Guidelines. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Packaging Trends and Consumer Insights. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Supplier contracts can make or break a packaging program. Without the right terms, buyers risk price volatility, missed lead times, and inconsistent product quality. In 2026, negotiating smart contracts is essential for controlling costs, securing reliable supply, and meeting compliance requirements. Why Packaging Contracts Matter Cost stability: Protects against sudden raw material price spikes. Supply security: Ensures availability during peak demand. Quality control: Aligns suppliers with testing and compliance standards. Operational efficiency: Streamlines purchasing and reduces administrative burden. Key Terms Buyers Should Negotiate Volume commitments: Secure better pricing with accurate forecasts. Price adjustment clauses: Define when and how costs can change. Lead times and delivery windows: Avoid shortages and production delays. Testing and compliance: Require ISTA, ASTM, or FSC certification where applicable. Sustainability commitments: Ensure suppliers align with environmental goals. Risks of Weak Contracts Paying inflated prices during market fluctuations. Receiving inconsistent corrugated strength or print quality. Missed shipments leading to costly expedited freight. Difficulty meeting retailer or regulatory compliance. Best Practices for Buyers in 2026 Leverage data: Use past order history to negotiate realistic volumes. Dual sourcing: Maintain backup suppliers for risk management. Annual reviews: Reassess terms to reflect changes in demand and compliance. Collaborative approach: Treat suppliers as partners, not just vendors. Packaging Solutions with Brown Packaging Brown Packaging helps buyers secure strong supplier contracts that balance cost, quality, and supply chain reliability. Our partnerships and industry expertise ensure your packaging program is protected for 2026 and beyond. Contact us to discuss supplier solutions. References Soroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals.Fiber Box Association. (2024). Corrugated Packaging Market Outlook. Retrieved from https://www.fibrebox.orgSustainable Packaging Coalition. (2023). Supplier Standards for Sustainable Packaging. Retrieved from https://sustainablepackaging.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Packaging compliance is no longer optional—it’s a requirement for accessing retail shelves, shipping networks, and international markets. In 2026, buyers must navigate evolving regulations around sustainability, labeling, and testing to avoid costly fines, rejected shipments, or damaged customer relationships. Why Compliance Matters in 2026 Retail requirements: Major retailers demand FSC, ISTA, and sustainability certifications. E-commerce standards: Carriers enforce dimensional weight and package testing rules. Global trade: Export packaging must comply with ISPM 15, ASTM, and ISO guidelines. Consumer trust: Transparency in packaging claims impacts purchasing decisions. Key Compliance Areas for Buyers Material sourcing: FSC-certified corrugated and board for sustainability. Labeling standards: GS1-compliant barcodes and accurate product details. Durability testing: ISTA and ASTM protocols for drop, vibration, and compression. Sustainability regulations: Requirements for recyclable or compostable materials. Chemical restrictions: Compliance with FDA, EU, or state-specific standards. Common Compliance Challenges Keeping up with frequent regulatory changes. Managing multiple certifications across suppliers. Balancing compliance with cost-efficiency. Verifying supplier claims for sustainability. Best Practices for Staying Compliant Audit suppliers annually to confirm certification validity. Run internal packaging tests before scaling. Track regulatory updates for each region you ship to. Work with experienced partners who understand industry compliance. Packaging Solutions with Brown Packaging Brown Packaging helps buyers meet 2026 compliance standards with FSC-certified materials, ISTA-tested designs, and regulatory expertise. Our team ensures your packaging meets retailer, carrier, and sustainability requirements. Contact us to keep your program compliant. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgInternational Safe Transit Association (ISTA). (2023). ISTA Testing Procedures for Transport Packaging. Retrieved from https://ista.orgGS1. (2024). Global Standards for Packaging and Labeling. Retrieved from https://www.gs1.org (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

In 2026, sustainability is no longer just a trend—it’s a buyer expectation. Forest Stewardship Council (FSC) certification has become a key benchmark for responsible packaging, signaling that materials are sourced from responsibly managed forests. For packaging buyers, FSC certification is more than a compliance checkbox—it’s a brand value that influences purchasing decisions, retailer acceptance, and customer loyalty. What Is FSC Certification? The Forest Stewardship Council certifies that paper-based packaging materials are sourced from forests managed for environmental responsibility, social benefit, and economic viability. FSC Mix: Packaging contains a blend of FSC-certified and controlled wood. FSC Recycled: Packaging is made entirely from recycled fiber. FSC 100%: Packaging is sourced only from FSC-certified forests. Why FSC Matters to Buyers in 2026 Retail access: Many major retailers now require FSC-certified packaging. Sustainability goals: Aligns with corporate ESG and carbon reduction commitments. Consumer trust: Customers recognize the FSC label and view it as credible. Global compliance: Meets international sustainability regulations. How FSC Certification Strengthens Brand Value Differentiation: Stand out with certified sustainable packaging. Marketing advantage: FSC logos reinforce eco-friendly messaging. Risk reduction: Verified sourcing prevents greenwashing claims. Customer loyalty: Environmentally conscious buyers prefer certified products. Challenges in FSC Implementation Limited supply of certain FSC substrates. Higher costs compared to non-certified materials. Need for supplier audits and documentation. Packaging Solutions with Brown Packaging Brown Packaging partners with buyers to integrate FSC-certified materials into corrugated boxes, folding cartons, and retail packaging. Our solutions support sustainability while maintaining cost efficiency and protection. Contact us to strengthen your brand with FSC-certified packaging. References Forest Stewardship Council (FSC). (2023). FSC Certification Guidelines for Packaging. Retrieved from https://fsc.orgSustainable Packaging Coalition. (2023). Consumer Insights on Sustainable Packaging. Retrieved from https://sustainablepackaging.orgSoroka, W. (2009). Fundamentals of Packaging Technology (4th ed.). Institute of Packaging Professionals. (714)300-0650 request@brownpackaging.com Most Recent Posts: Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Sustainable Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

Home » Custom Packaging: Everything You Need to Know and More

In an era where electronic components and sensitive products are more prevalent than ever, understanding and utilizing anti-static packaging has become essential for businesses. This blog post delves into the significance, types, and considerations of anti-static packaging, highlighting its critical role in protecting sensitive items from static damage. The Importance of Anti-Static Packaging Static electricity can be a silent but deadly foe for electronic components and other sensitive products. Even a small amount of static discharge can damage or destroy these items. This is where anti-static packaging plays a pivotal role, by preventing the build-up of static electricity and protecting the products during storage and transportation. Types of Anti-Static Packaging Anti-Static Bags: These are the most common type of anti-static packaging. Made from plastic with an anti-static coating, they prevent the build-up of static inside the bag. Ideal for small electronic parts like RAM, hard drives, and motherboards. Conductive Bins and Totes: Used for larger components or for transportation of multiple items, these containers offer a conductive surface that dissipates static charge. Foams and Bubble Wraps: Anti-static foam and bubble wrap provide cushioning while also preventing static build-up, making them perfect for delicate or shock-sensitive items. Static Shielding Bags: These offer more protection than regular anti-static bags by also protecting the contents from static charges outside the bag. Why Choose Anti-Static Packaging? Protects Sensitive Equipment: The primary purpose is to safeguard electronic components and other static-sensitive products from static damage. Reduces Returns and Complaints: By ensuring products arrive in working condition, anti-static packaging reduces the likelihood of returns and customer complaints. Compliance with Industry Standards: Many industries mandate the use of anti-static packaging for certain products, making it not just a choice but a compliance issue. Considerations When Selecting Anti-Static Packaging Type of Product: The nature of the product (size, sensitivity to static, value) will determine the type of anti-static packaging needed. Cost-Effectiveness: While essential for certain products, anti-static packaging can be more expensive than standard options. Balancing cost with necessity is key. Environmental Impact: Some businesses may seek eco-friendly options, as traditional anti-static materials can be less biodegradable. Storage and Handling Requirements: Certain anti-static packaging materials may have specific storage or handling requirements to maintain their effectiveness. Conclusion Anti-static packaging is a critical component in the safe handling and shipping of electronic and static-sensitive products. Understanding the different types and their appropriate applications can help businesses protect their products, reduce losses, and maintain customer satisfaction. As technology continues to evolve, the importance of anti-static packaging is only set to increase, making it an indispensable part of modern product handling and logistics. If you are interested in anti-static packaging, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Anti-Static Packaging Facebook Twitter LinkedIn Pinterest Relevant Posts

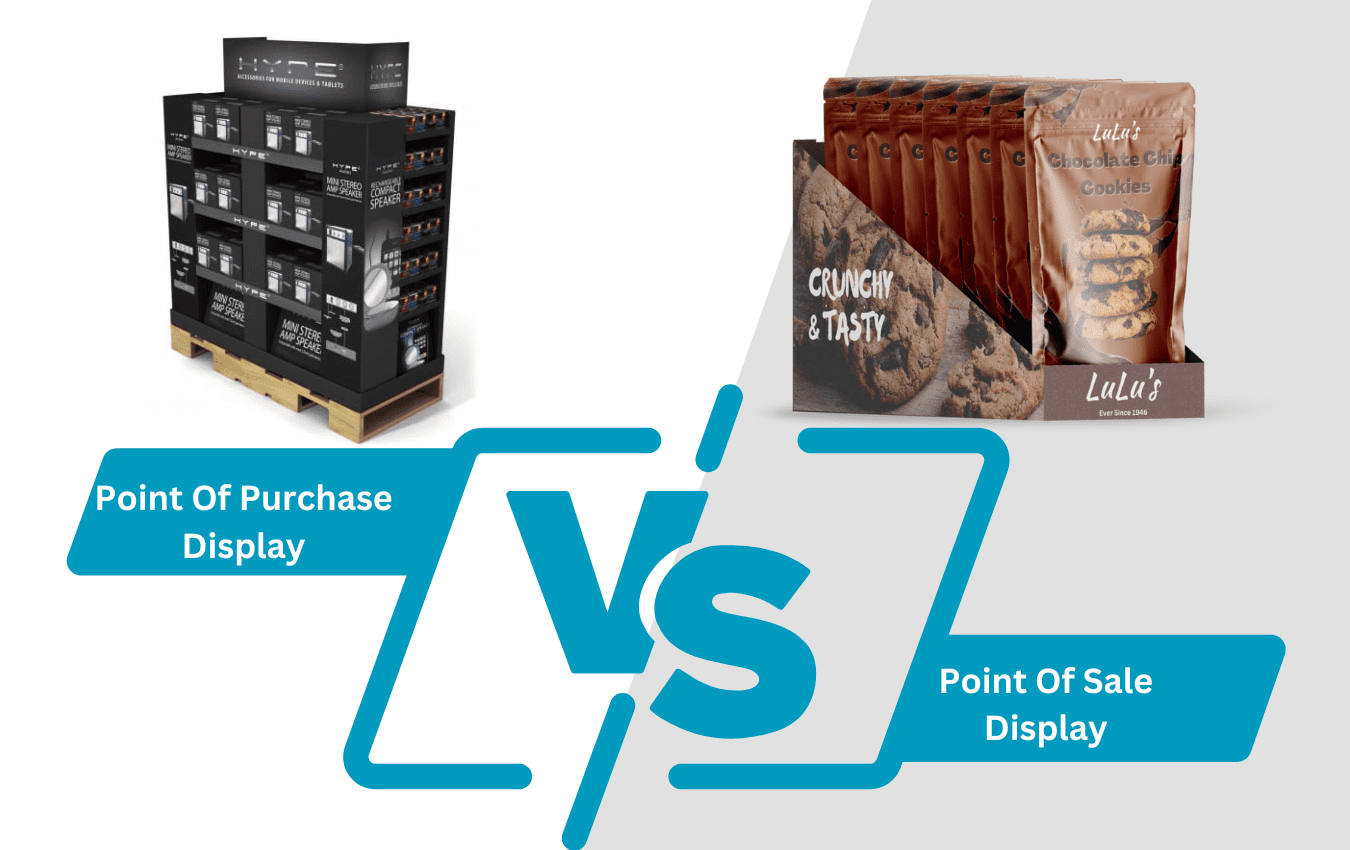

Displays play a key role in marketing and selling your product in stores. With the goal of grabbing the attention of a customer, it is important to choose the right style. There are many factors to keep in mind when deciding which display is best for your business needs. The two main types are POP and POS displays. Making the decision between both will be based on your product and your overall company goals. With a well-designed display you can showcase your products most impressive features and have a better chance of catching your customer’s attention. It is important to understand the differences between the two in order to choose the best display for your business needs. What is a POP Display? A POP display refers to point of purchase which is the physical location where a consumer decides they would like to buy a product. These displays need to appeal to the customer and convince them to make a purchase. It is important that POP displays are customized with eye catching designs, in order to convince the costumer to purchase the product. These displays are meant to be placed in highly trafficked areas to ensure the maximum number of views. There are three main types of POP displays. The first being temporary which is made with corrugated material. This is the cheaper to produce compared to the longer shelf life displays. Shelf life for this is up to 6 months. Next being semi-permanent, which is made with heavy duty corrugated, metal, wood, acrylic, and glass. The shelf life for this is 6 months to a year. Lastly is permanent which is made with plastic, metal, wood, glass and other durable materials. The shelf life is up to 3 years which makes it the longest lasting POP display. POP Display Styles: Floor Display: Typically located in aisles with shopping access from all sides. Pallet Display: Located on a pallet and can vary in three sizes (Half, Quarter, Full) Power Wing (Sidekick) Display: Versatile and can be placed on endcaps or the sales floor. Dump Bin: Placed on the sales floor and can be accessed from all sides. Pallet Skirt/Wrap: A corrugated covering of a stack of pallets, which is used to hold up and display products. Floor Pallet Power Wing (Sidekick) Dump Bin POP Display Strengths: Increase brand awareness Showcase products and new items Breakaway from competition on shelf Placed in high traffic areas What is a POS Display? A POS display refers to point of sale which is the specific area where the sale takes place. These are the displays that customers interact with near the checkout or register. The purpose of these are to engage the customer in impulse purchasing. This is usually for items you didn’t plan on purchasing, but after seeing the item at check out, you impulsively chose to buy it. Since these are placed at checkouts, it’s almost a guarantee that customers will see your product. Although these displays are small, it is still important to have an eye catching design in order to draw in the customer. Since these displays are smaller, they are best for small items and those that are individually packaged. Common examples of these are; drinks, candy, gum, and other small items located at the register. POS Display Styles: PDQ Trays: Designed to fit in small places and maximize the use of retail place. Counter Top: Displays that are usually on a counter and designed to hold small products and fit them in compact areas with limited space. Power Wing (Sidekick) Display: Versatile and can be placed on endcaps or the sales floor. PDQ Tray Counter Top Display POS Display Strengths: At checkout, all customers will see Targets impulsive buyers Usually smaller and cheaper products Showcase products and new items When to Choose a POP or POS Display: Point of Purchase More costly Bigger displays More products Versatility and mobility to place display throughout the store Variety of display options and best for design Point of Sale Less costly Smaller/individually packaged products Less variety of products Placed at check out Targets impulse purchases Summary: Choosing the Right Display Displays are a great way to stand out among your competitors. These two displays although similar, give two different approaches when it comes to showcasing your product. Choosing the right display for your business needs is important. They can come in many sizes, shapes, and designs with the common purpose of promoting and displaying your products. You must take many factors into consideration when making that decision. If you need help deciding which display would be best for your business needs, then contact Brown Packaging today so one of our packaging specialists can assist you. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. Custom Displays Facebook Twitter LinkedIn Pinterest Relevant Posts

In the fiercely competitive world of retail, brand recognition is the key to success. Standing out amidst a sea of choices requires a strategic approach, and one effective method to achieve this is through the art of consistent Point-of-Purchase (POP) displays. These displays are more than just functional; they are an opportunity to reinforce your brand identity and leave a lasting imprint on your customers’ minds. The Role of Brand Recognition in Retail Brand recognition is the ability of consumers to identify and associate a brand with specific attributes, values, and emotions. It’s not just about recalling a company’s name; it’s about forging a strong connection that leads to trust, loyalty, and increased sales. The Power of Consistency in Branding Consistency is the cornerstone of effective branding. It entails presenting a unified and harmonious image across all touchpoints, whether online, on packaging, or in-store displays. Consistency builds familiarity, making it easier for customers to connect with your brand on a profound level. Leveraging POP Displays for Cohesive Branding POP displays, strategically placed within a retail environment, offer a golden opportunity to reinforce consistent branding. These displays serve as visual ambassadors, conveying your brand’s essence in a matter of seconds. When executed seamlessly, they bridge the gap between online and offline experiences. Key Elements of Consistent POP Displays Color Palette and Typography Consistency in color and typography is a visual hallmark of your brand. Opt for a color palette that aligns with your brand’s personality and resonates with your audience. Whether bold and vibrant or minimalistic and subdued, the colors you choose should reflect your brand’s identity. The same holds true for typography—choose fonts that are not only readable but also reflective of your brand’s tone. Logo Placement and Sizing Your logo is your brand’s visual signature. Ensure it’s prominently placed on all your POP displays. Maintain a consistent logo size, regardless of the display’s dimensions. This consistency reinforces brand recognition and fosters a cohesive appearance. Messaging and Tone Craft a clear and succinct brand message that effectively communicates your value proposition. Keep a consistent tone across your messaging—whether it’s light-hearted, professional, or inspirational. A unified tone helps customers identify and resonate with your brand’s voice. Visual Style and Imagery Select a visual style that aligns with your brand’s essence. Whether through photography, illustrations, or graphics, make sure your chosen style remains consistent across all displays. A cohesive visual approach enhances brand recognition and makes your displays instantly recognizable. Creating a Unified In-Store Experience Consistent POP displays contribute to a unified in-store experience. When customers encounter consistent visual elements across various products and displays, it reinforces a sense of familiarity and trust. This experience plays a vital role in cultivating long-lasting customer relationships. Benefits of Consistent Branding in POP Displays Instant Recognition: Customers can quickly identify your brand. Professionalism: Consistency conveys professionalism and dependability. Trust and Loyalty: Familiarity fosters trust, leading to customer loyalty. Unified Brand Identity: Consistency maintains a unified brand image across touchpoints. Tips for Implementing Consistent Branding in POP Displays Conduct a brand audit to identify key visual elements. Establish clear brand guidelines for your POP displays. Educate your staff on the significance of consistent branding. Regularly review and update displays to ensure alignment with your brand. Measuring the Impact of Brand-Centric POP Displays Monitor metrics such as customer engagement, sales lift, and customer feedback to gauge the impact of consistent POP displays on brand recognition and overall performance. Future Trends in Brand-Focused POP Displays Explore emerging trends like interactive displays, personalized experiences, and the integration of technology. Discuss how brands can incorporate these trends while maintaining consistency. By harnessing the potential of consistent POP displays, retailers can forge a commanding brand presence that resonates with customers, nurtures loyalty, and propels long-term success in today’s dynamic retail landscape. If you are interested in Point of purchase displays, then partner with Brown Packaging today to get started. (714)300-0650 request@brownpackaging.com Most Recent Posts: Categories: Corrugated Ecommerce ESD Design Display Flexible Packaging Foam Folding Carton Packaging Plastic Packaging Pouch Printing Protection Retail Rigid Box Thermoform Sustainability Subscribe To Our Newsletter By submitting your information, you agree to our terms and conditions and privacy policy. POP Displays Facebook Twitter LinkedIn Pinterest Relevant Posts